Object Based Sculpture and Design with Leah, from Anderson Ranch

By Maryann Valentine

Leah Aegerter grew up in Seattle, Washing with a passion in art and sculpting. She completed her BFA at the Rhode Island School of Design in Providence, RI, where she got a technical education in woodworking, steel fabrication, casting and mold making for a variety of materials, including metals. She also took electives in video and performance arts, and during her senior year at RISD, she took an elective in digital fabrication where she learned Rhino and had a few opportunities to output designs using 3D printers, CNC machines and laser cutters. During her senior year, she applied and began her internship at Anderson Ranch in Snowmass Village, Colorado, where she would be assisting workshops in digital fabrication, woodworking and sculpture. Throughout this internship at Anderson Ranch, she gained a lot of knowledge and proficiency in working with CNC machines in the fabrication lab. She furthered her knowledge in CAD/CAM and outputting by working closely with the variety of machinery, like the Techno CNC Titan Series CNC Router and HD II Tabletop CNC Router, inside the digital fabrication lab on campus. At the beginning of 2019, Leah became the Studio Coordinator of Digital Fabrication at Anderson Ranch, and quickly made the ‘FabLab’ her newest home.

Anderson Ranch is a 55 year old, non-profit art center, based in Snowmass Village, Colorado that hosts a variety of workshops for all skill and age levels. The center offers a variety of different programs all year long, ranging from weekly intensive workshops to artist residencies across disciplines. Digital fabrication workshops range in content from CNC flat pack furniture to 3D printing and metal casting workshops that include using 3D prints with mold making in 3D sculpture, etc. The center works closely with the community in the Roaring Fork Valley, as well. The digital fabrication lab at Anderson Ranch is an interdisciplinary studio – meaning all projects held in the fab lab are in collaboration with another department at Anderson Ranch. Leah’s main goal as the Studio Coordinator of the lab is to integrate 3D technology with traditional craft and hand processes, by taking advantage of the limitless digital abilities of the CNC machinery in the fablab, from Techno CNC Systems.

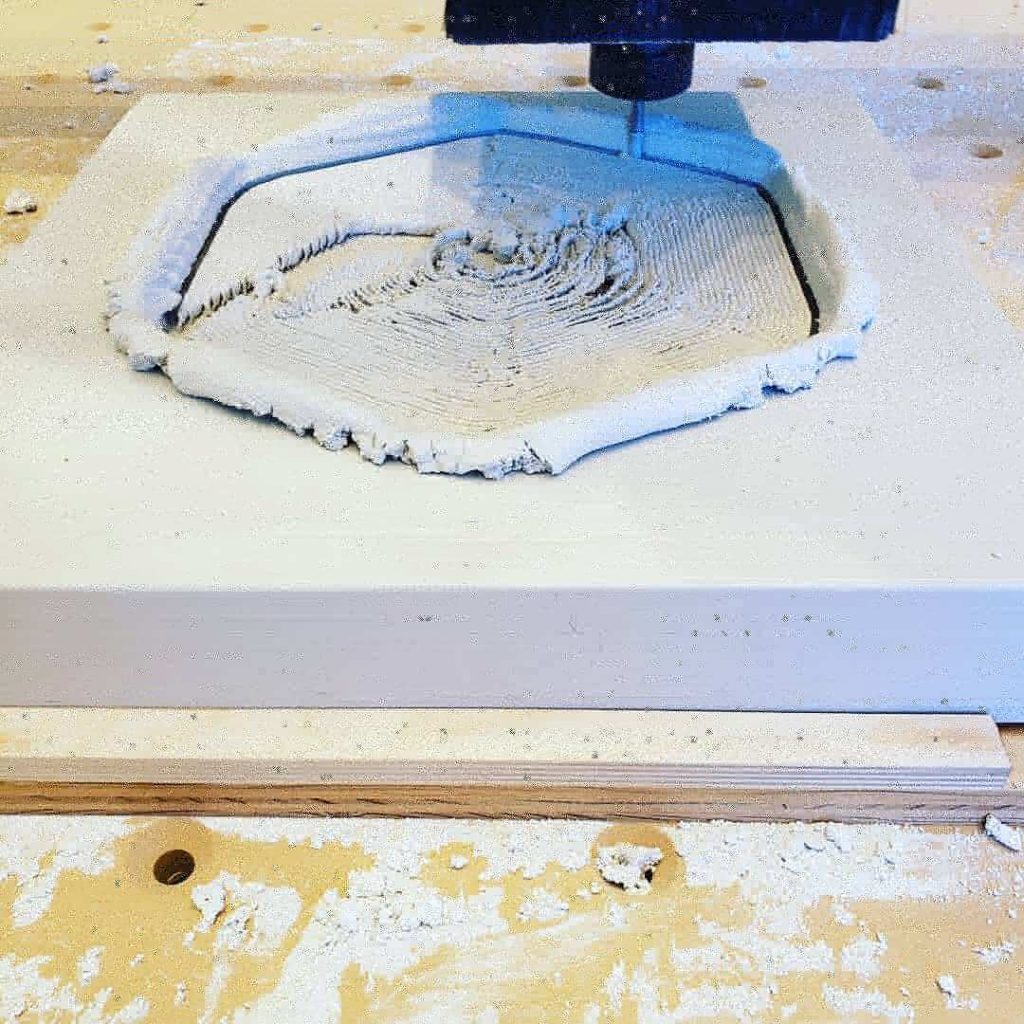

“In our fablab, we use the CNC machines for 2D and 3D operations for the different workshops we host on campus. Students are given lessons on how to use the machinery, and are able to work closely with each CNC machine that we have to offer. We currently have 2 CNC routers from Techno CNC Systems. We wanted to upgrade our digital fab lab in 2020, so we invested in our 2nd and 3rd CNC routers from Techno. We now upgraded to a Titan Series CNC model with an automatic tool changer spindle, and a smaller, more-compact version of the Titan, their HD-II Tabletop model, to fit in a smaller area inside our digital fabrication lab. Both machines are used during various workshops to help integrate digital abilities while continuing to teach traditional craft to our students”. Anderson Ranch recently renovated their digital fabrication lab, moving the lab across campus to a bigger studio, where they were gifted money to purchase two new CNC routers from Techno CNC. “In one of my favorite workshops, we use the Titan Series to make molds for slip-casting and ceramics. We make the plaster molds from foam, or directly carve plaster blocks, and cast into those molds. Students learn both digital and traditional methods for making plaster molds”.

Leah also uses the CNC routers for her own personal projects. “I use the machines to carve textures of 3D scans from the outdoors. I use an app called Trnio, an app that transforms your iPhone into a handheld 3D scanner and flawlessly carries real life objects and scenes into a digital space. Basically, I take photos of an object outside, like a rock or a leaf, and process the scans back at home. I then do a 1:1 representation of the texture by using the machines to carve them out on different hardwoods with a very fine pass. This allows for little to no finishing required. And from there, I take that block of wood and cut it up in a variety of ways, to then reassemble the pieces into a new composition. These 3D applications are extremely exciting to me as a sculptor”.

Artists throughout campus also use the CNC machines in the digital fabrication lab at Anderson Ranch for their own personal projects, as well. “We had an artist resident come in to work with copper plates on the HD II Tabletop recently. She used a diamond tip bit and unplugged the spindle so the machine was not spinning while routing; it was just engraving on a copper plate. She then took her plate back to the print shop and ran it through the press … the results were very exciting”.

Currently, Anderson Ranch hosts a variety of classes that incorporate CNC technology into the art curriculum. The center hosts different woodworking classes that use the CNC for flat pack furniture making and stack laminated furniture making where students cut out plywood forms and laminate them back together. For next year, Leah has programmed a workshop that combines digital and traditional carving techniques, where students will learn to carve basic 2D pockets and contour paths with both of the Techno CNC machines in the fabrication lab. They will then take the panels cut on the CNC routers, and learn to carve them by hand using gauges to create traditional carved textures. The center also hosts digital foundry classes that uses the Techno CNC machinery for carving foams to use for sand molds and metal casting.

“The biggest pro of having access to these CNC routers is the capabilities, in general. We have laser cutters and 3D printers in our fab lab as well, but the CNC routers offer so much more. The CNC machines offer both the capabilities from the laser cutter and 3D printers combined, and then some. These Techno CNC machines allow us the ability to use a wide variety of different materials, at different sizes and thicknesses, as well. This is a huge advantage for us while we study and practice different art techniques while designing and hosting classes. Another benefit of the CNC machinery is having not just one, but two. We have double the capabilities for students to work hands-on with the routers. This advantage allows for students to have more one on one time with the routers, and allow for our workshops to flow smoother while teaching CAD/CAM, new techniques, cutting tips, and more. We are extremely pleased with how our routers run, and give us and our students the ability to carve something out of thicker hardwoods for example, like my rock textures – it makes the process truly unique. We can’t wait to begin working with our new 4th axis rotary table and testing different tool paths. We are seeing that as Universities and schools become more accustomed to using CNC technology, incorporating it into their everyday curriculums, the learning curve decreases and the technology becomes more accessible to our program participants.”

Discover Anderson Ranch

Our Mission

At Anderson Ranch, we recognize human beings’ lifelong need to develop personal creativity and to discover, learn and grow. Artists of all levels come from across the country and around the world to explore new ideas, hone their art making skills and engage in meaningful dialog at the Ranch. Both an international center and a close community, Anderson Ranch welcomes adults, art students, children and teens―from beginners to the leading artists of our time.

The Studios

What you need, when you need it.

Our artistic studios offer 55,000 square feet of space in which to work, in all eight of the Ranch’s artistic disciplines: Ceramics, Digital Fabrication, Sculpture, Furniture Design & Woodworking, Woodturning, Painting & Drawing, Printmaking, and Photography & New Media.

Inside you’ll find impeccable spaces for art making and state-of-the-art equipment, all specifically designed to feed the passion of the artists who come to Anderson Ranch to make art, learn new skills and share ideas.

About Leah:

Leah Aegerter

Studio Coordinator, Digital Fabrication at Anderson Ranch

Leah Aegerter is an artist working in object-based sculpture, furniture, and installation. She received a BFA in Sculpture from the Rhode Island School of Design in 2017 and is the Studio Coordinator for Digital Fabrication at Anderson Ranch.

Leah’s Links:

Website: https://www.leahaegerter.com/

Learn more about our “Titan” Series CNC Router: https://technocnc.com/titan-series-cnc-router/ Explore our Full Line of CNC Routers Here: https://technocnc.com/cnc-routers/

► Contact us for more info: 631-648-7481 or email: technosales@technocnc.com

Please Like and Subscribe to our YouTube Channel! Stay tuned for more CNC router and CNC plasma cutting machine videos, DIY projects, how-to’s, builds, demo’s and more. We feature CNC cutting with different applications such as wood, plastic, aluminum, and other materials. ► Subscribe to our YouTube Channel: https://www.youtube.com/channel/UCEkd9rWdBXJj-LICGiougHA

► Instagram: https://www.instagram.com/technocnc/?hl=en

► Shop our Online CNC Site: www.technocncshop.com

► Subscribe to our CNC email list for deals and promotions

** Notice the efficiency & accuracy of our CNC routers – minimal production time, impeccable cut quality, smooth finishes, and limited material costs, as our CNC machines are programmed to utilize the entire sheet of material, leaving little to no wasted material between cuts **

Our Family of CNC routers represents 32+ years of CNC research and development. Since 1986, Techno CNC Systems has been solving the toughest manufacturing challenges. We use our CNC experience to help sign makers, woodworkers, mill workers, artists, general fabricators and more with their production needs. Our goal is to help businesses create more parts by spending less money and provide companies with the most advanced CNC technology.. Our CNC equipment is designed to route, carve, drill, and engrave in wood, plastic, foam, and aluminum for all businesses looking to better their company. Our Mission Techno has sold and serviced thousands of CNC machines worldwide. We believe that high quality CNC machinery ensures reliable cutting and machine longevity. It has become our mission to remain price conscious while delivering CNC solutions to businesses all across the globe. We are continuously studying technology and designing our own equipment to better serve our customers. Here at Techno, we produce a vast number of machine models to meet any and all production needs and budgets. Our full line CNC routers and CNC plasma cutters consist of large format and small table top sizes with a vast assortment of accessories to meet any production need.

Our Educational Sector

We also has a special educational CNC line up for schools and universities looking to Future Start their students! Are you a school or University looking for high speed, affordable industrial quality CNC Routers and/or CNC Plasmas? You are at the right place. Our Educational CNC routers and CNC plasma cutters come in a wide range of sizes with work areas available from 2″ x 3″ to 5′ x 10′. All machines offer endless STEM opportunities. Every machine is also installed and supported by local Techno CNC Systems representatives to ensure a successful startup. Call today to get your CNC machining program off to the right start.