A Hybrid of Old and New Art and Anatomy, Using a Techno CNC Router

By Maryann Valentine

Marnie Blair is an artist from Northwestern Ontario, Canada. She received a BFA with distinction from Lakehead University and an MFA from the University of Calgary. She has studied at the Royal College of Art in London, UK, the Studio Art Centres International in Florence, Italy and has interned at Manhattan’s Lower East Side Print Shop. Blair has worked as the Print and Paper Facilitator at the Banff Centre, taught at Thompson Rivers University and is currently an instructor at Red Deer College. She has exhibited in numerous exhibitions nationally and internationally.

Marnie Blair, a mother – an artist- a wife – a professor- a cardiac arrest survivor and more, is one of the most fascinating and captivating practicing artists I’ve ever encountered. At only 19 years old, Marnie Blair became 1 in 100 people who survived cardiac arrest. Inspired by her own story, she became fascinated by the human body, and began incorporating anatomy into her print making. Her own experience represents the specific and direct physical relationship that exists between ICD and the electrical activity of the heart. Also an art instructor at Red Deer College in Red Deer, Canada, Marnie has also found herself utilizing the Techno CNC Systems LC 4896 from the Red Deer College, and creating one-of-a-kind art like I’ve never seen before. She uses her Implantable Cardioverter Defibrillator (ICD) as a starting point to examine questions that surround the intersection of technology and humanity. Her work explores the natural and the artificial and what it means to be dependent on a machine in order to live. This reliance on technology references our own increasing dependence on technology and its impact on our daily life.

“I’m a print maker. I do wood cuts, etchings and screen prints. Across the United States, print makers do not have access to a CNC router normally, but after working at Red Deer College for almost 4 years, they built the Center of Innovation and Manufacturing, which then allowed for a CNC router. The President of Red Deer College gave access to all students and faculty, allowing for anybody to utilize the router in its fullest potential. So naturally, I brought my students to the Center of Innovation and Manufacturing to utilize the Techno CNC router. My students and I made a 4×8 wood cut, printed it, and the rest was history. I was so fascinated with what the router could do, and how wonderful each piece was carved.”

About 6 months ago, Marnie was fully trained on how to use the router. She spent about 4 months in the studio learning the software and practicing how to carve. Then, she began routing images inspired by the imagery in an old found textbook she bought from an antique store. Her dual purpose was to try to recreate sweat books where people can go into a gallery and flip through her art, and with the router available, her vision could become a reality. “So far, I’ve spent this entire summer with the router, and I love the entire process. I love carving it and then hand painting each piece after.”

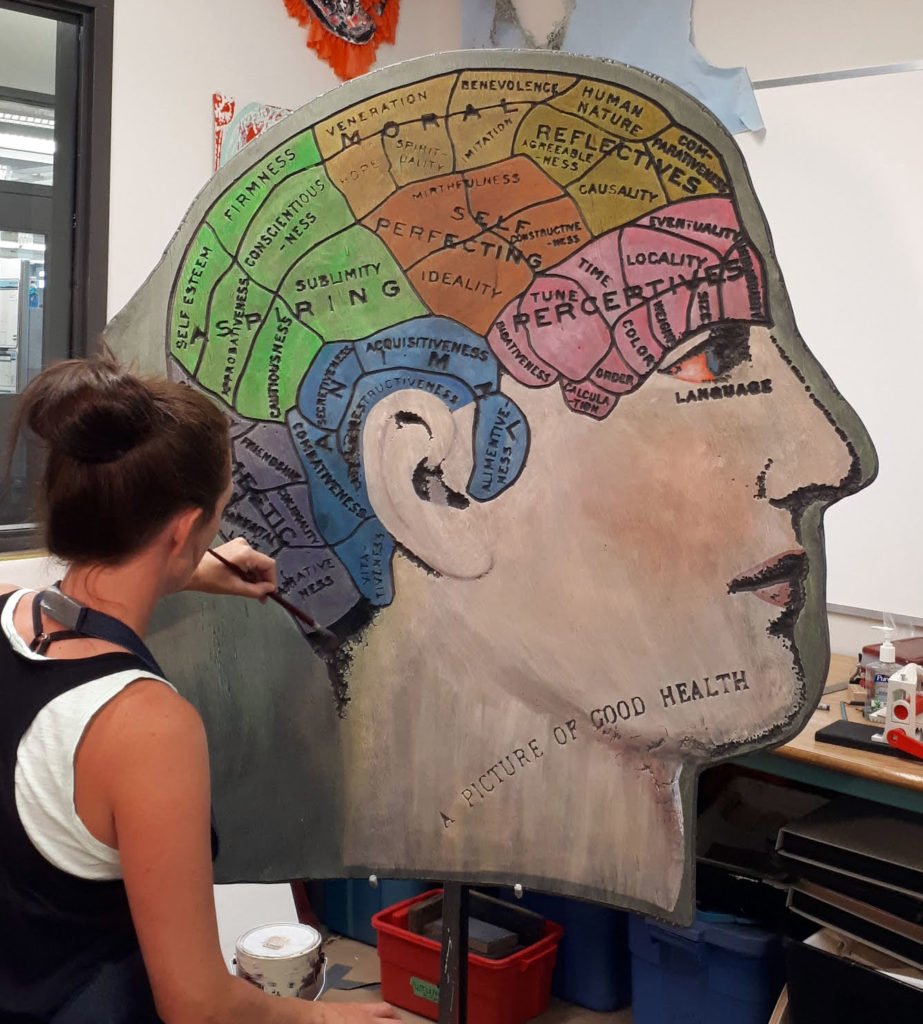

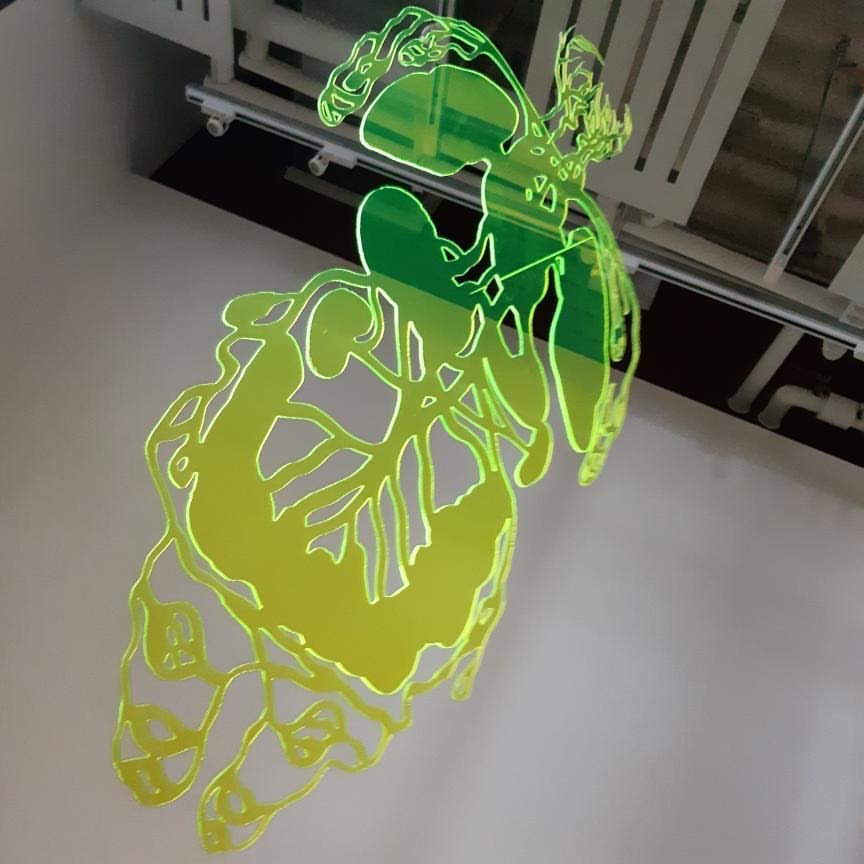

Marnie programs the router based off the image from her 1900s textbook, routes the image, hand paints the wood cut to match the colors used in the textbook, and then stamps the painted wood carving, creating a fascinating yet vintage inspired piece of art. Her work is meant to be a hybrid of old and new – woodcut is a traditional printmaking process that dates back to the Han Dynasty before 220 AD and new technology, using the CNC router to carve the imagery. “I am interested in how relying on a computer and machine in my artistic practice is similar to her own experience of relying on a machine, an implanted defibrillator, to ensure her body functions as it should.”

“Before the router, it would take me about a week to carve each one of my pieces. Now, I can make my art in double the time, and the carve is so much cleaner, neater, and faster. The router carves so beautifully, and adds another layer of information and aesthetic beauty to my work.”

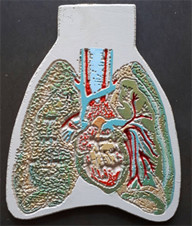

When she first attempted to route, Blair was practicing using 3D carving techniques. Due to long cycle times, she quickly learned that these techniques were not sufficient for her project. After playing around with the software capabilities and learning the ins and outs of the Techno CNC router, Marnie was able to reduce the file size, resulting in a reduced cycle time to complete her project. The time lowered from days and weeks, to hours and minutes. “I wanted to create a large back panel of the human body with a bunch of assembled pieces, like the lungs, the uterus, the intestines, etc. on top of it, yet when I inputted the large back piece into the router; it said it was going to take hours to route. I absolutely loved the beautiful pattern the router created on the wood… I didn’t want to go back to carving each piece to by hand. The router created this mesmerizing pattern on the wood that I would have never got if I had carved it by hand. I learned how to reduce my file size, in order to make my operating time a lot faster.”

Blair has carved a number of body parts. She has carved a shoulder, a hip bone, lungs, rib cages, a liver, intestines, a womb with a fetus, etc. “I want to carve every single organ I can find in my vintage medical textbook. I love the abstract ideas that scientists had about the human body many years ago, and am inspired by the different though process, the colors they used… the phenomenon’s about how the human brain is separated into different layers… I love it all, and I plan to recreate it using my knowledge and creativity paired with the Techno CNC router.” This work is the beginning of a larger body of work. Blair has started to carve more large pieces that will be painted – the 7 layers of the brain, eyes, ears, hands and feet, all based on medical flip charts. These pieces will be hinged like a book for viewers to flip through! “I am so happy with where I am with my art. I couldn’t work like this without the CNC router.”