Estop Loop Broken

Scenario:

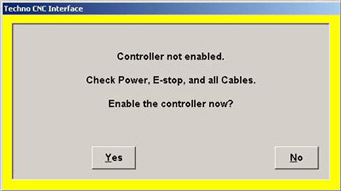

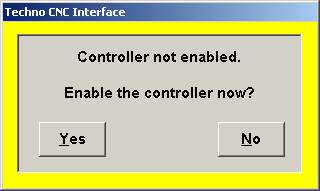

The ready light is blinking on the controller when the user attempts to enable, but the emergency stop is not the cause. The following screen persists:  or

or

Problem

The Emergency stop loop has been tripped. The emergency stop loop is run through all of the motors as well as the E-stop button. It must be determined which segment of the E-stop loop is broken.

Solution

Before doing any work on the machines, switch off and lock out power to the control box.

› Check all cables going into motors. Ensure they are completely engaged and screwed in tightly.

› Check all cables going into the control board inside the control box. Ensure they are completely engaged and screwed in tightly.

If the problem persists, you will next need to isolate the problem.

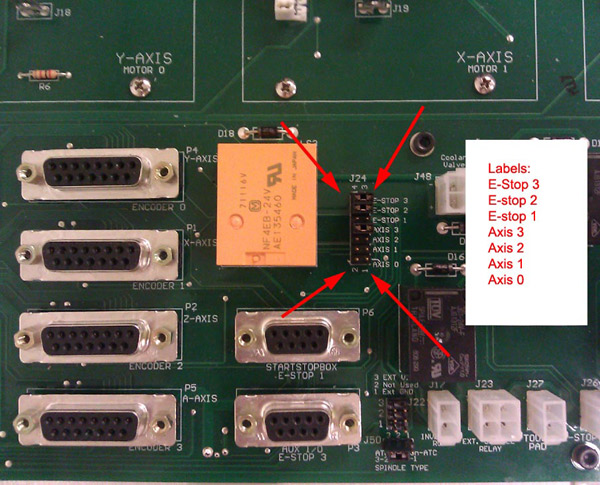

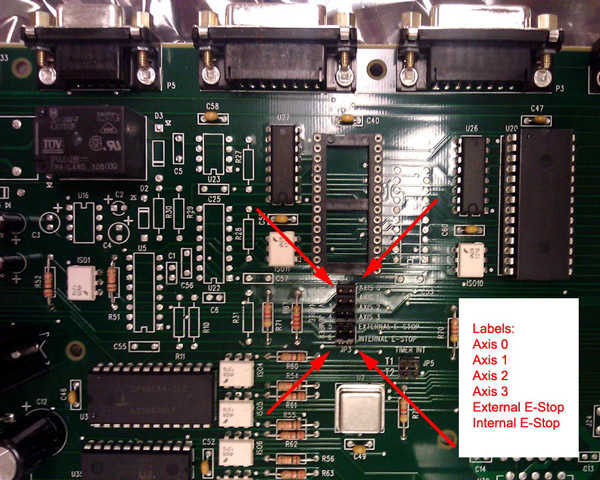

Find the jumper block on the control board. (Determine your Controller box)

LC Plus Control Board E Stop Jumper header  |

LC Control Board E Stop Jumper header |