The HDS Series

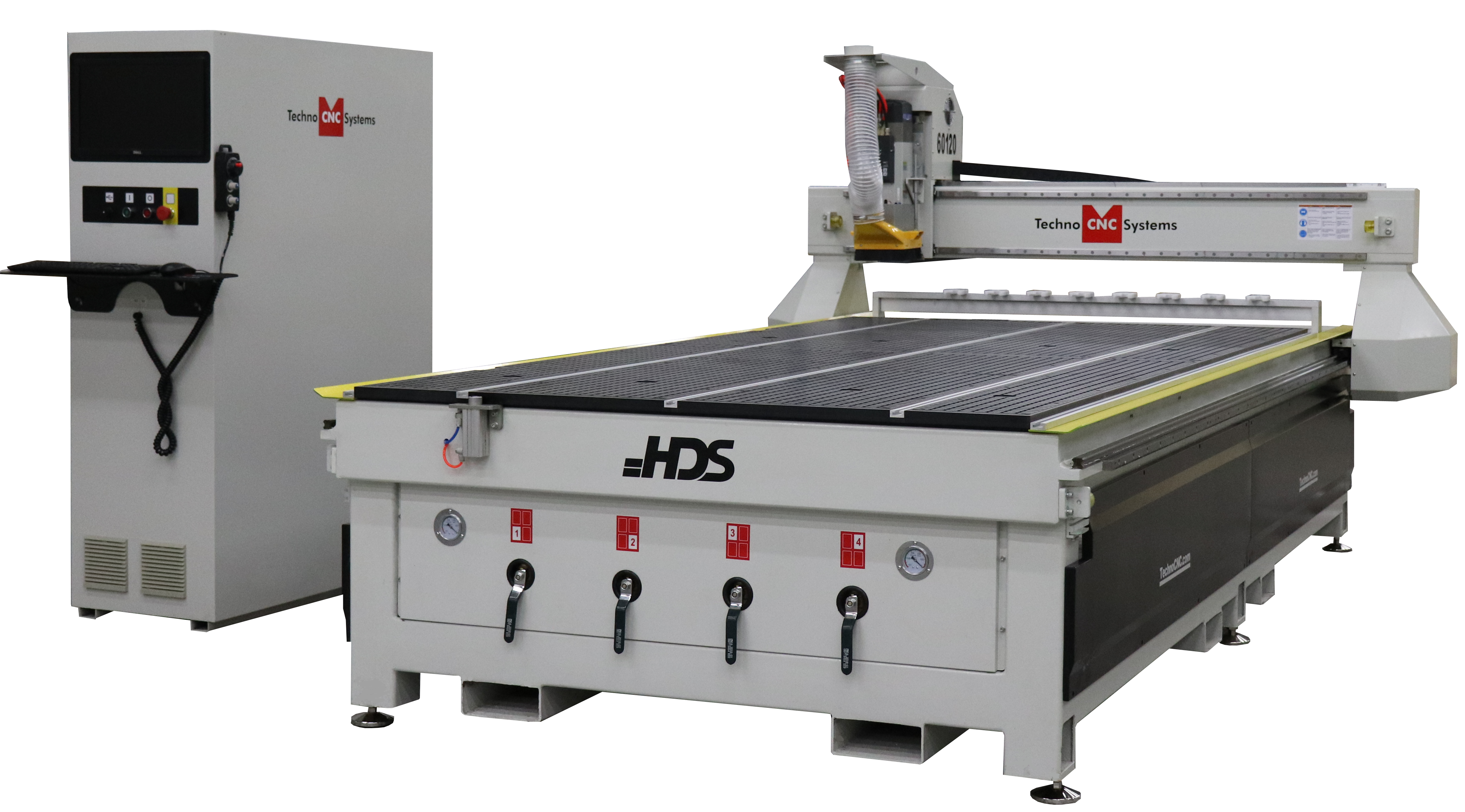

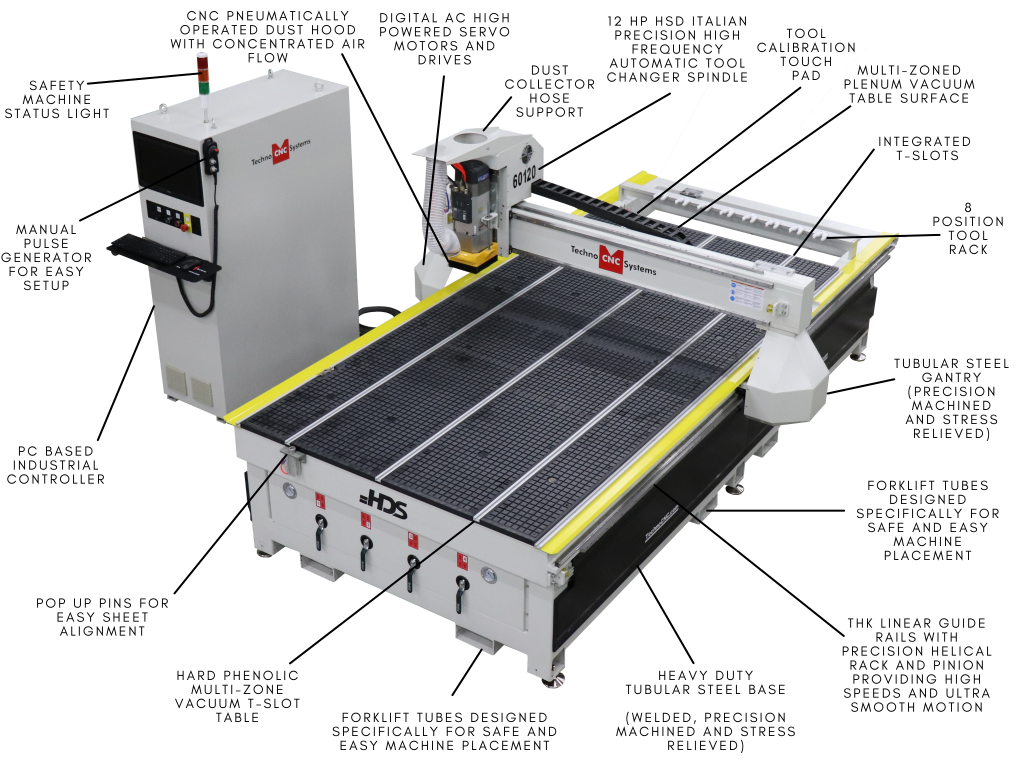

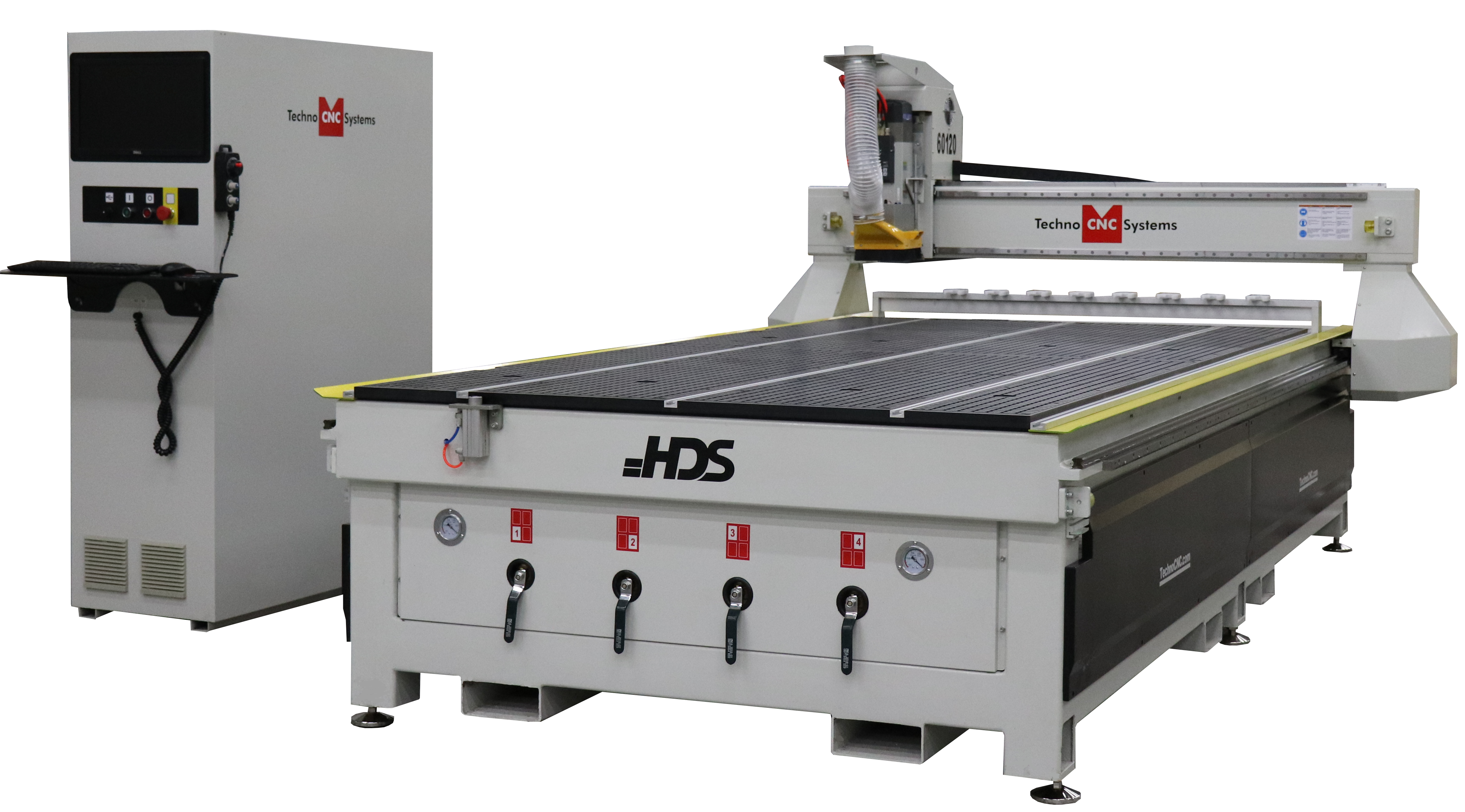

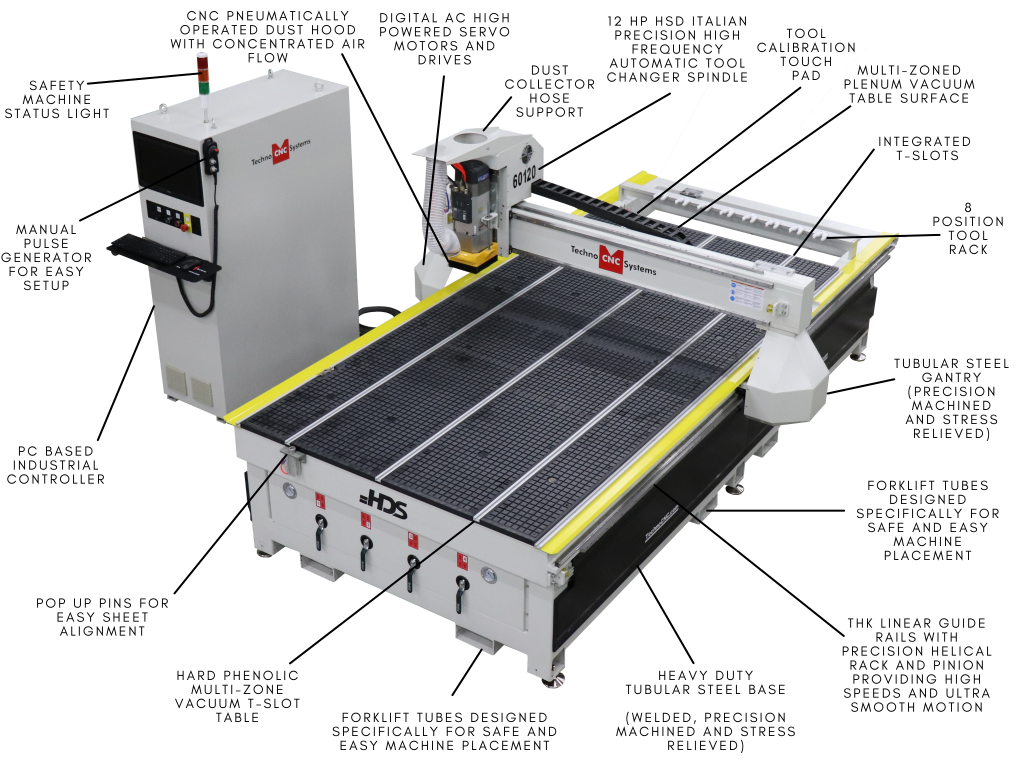

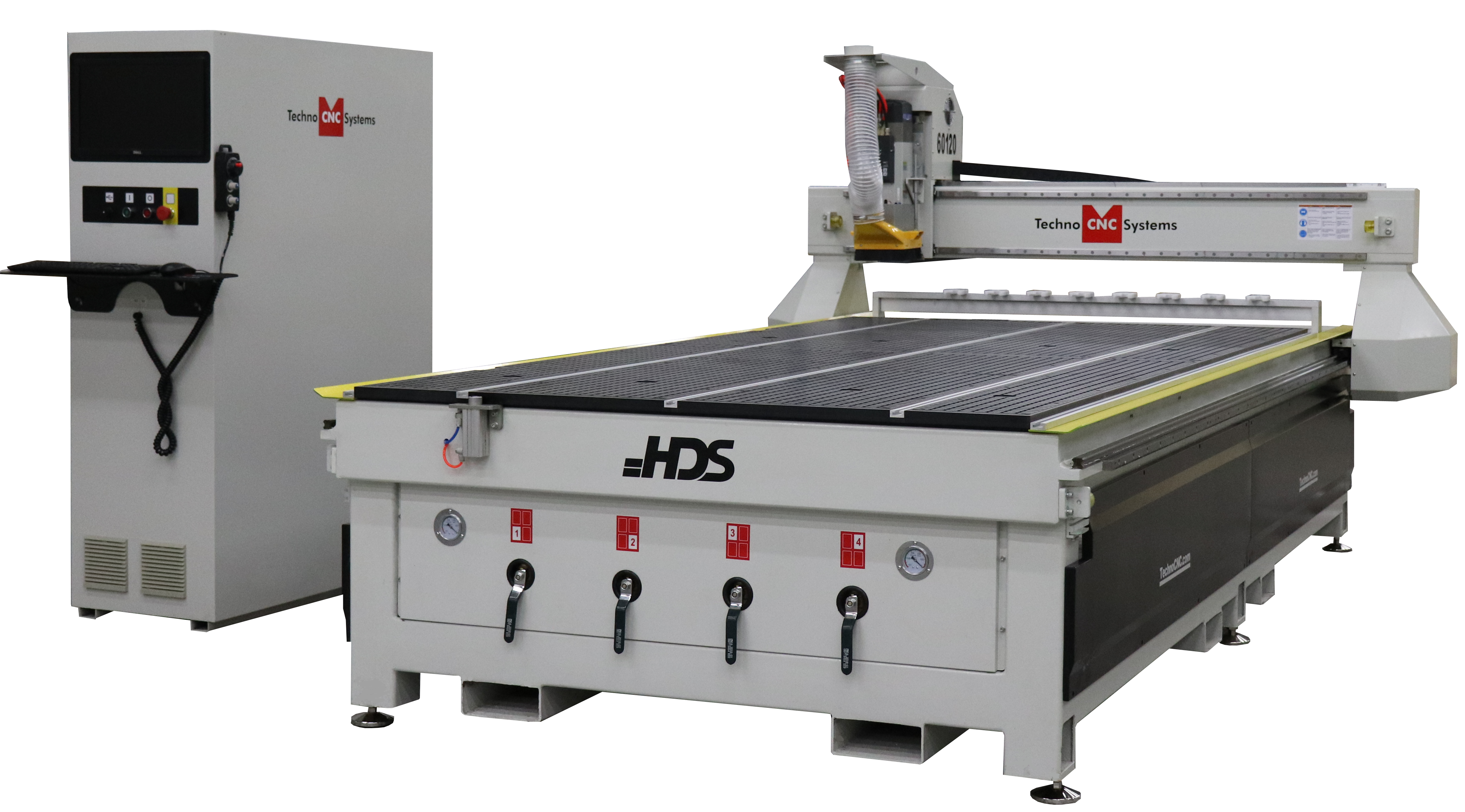

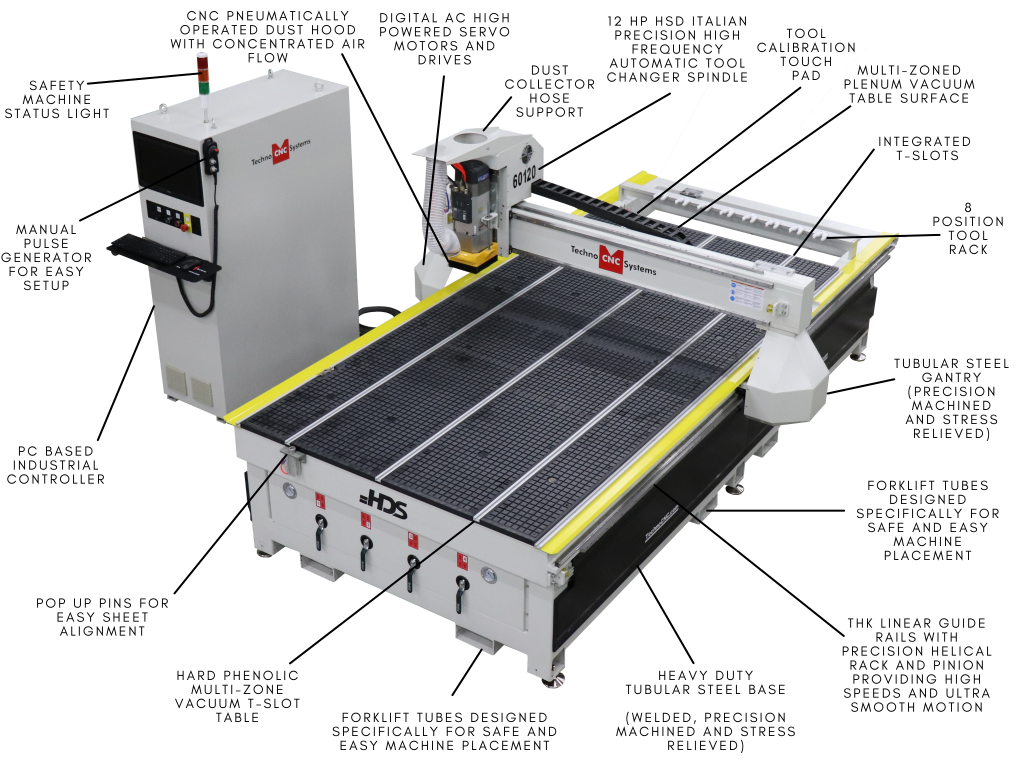

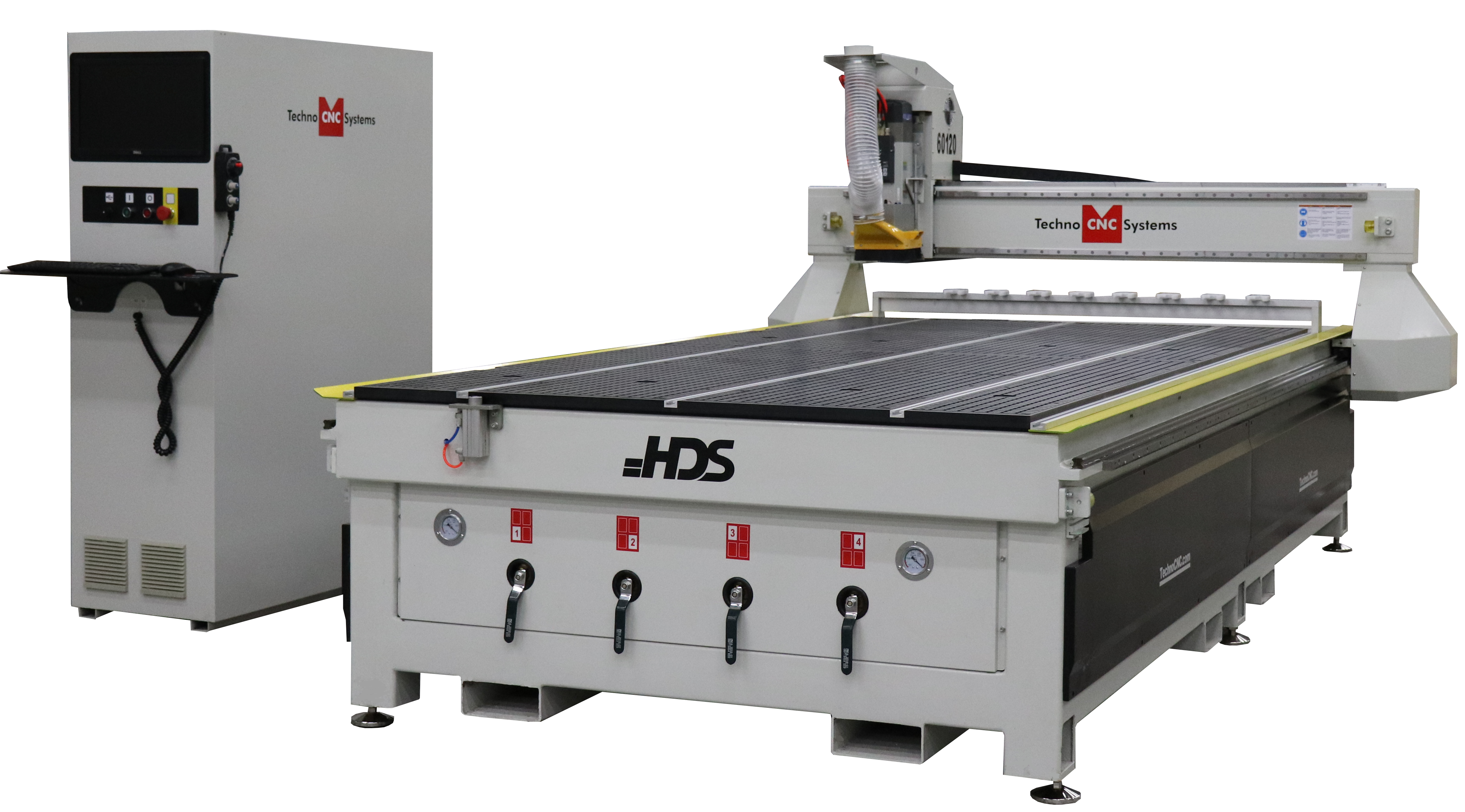

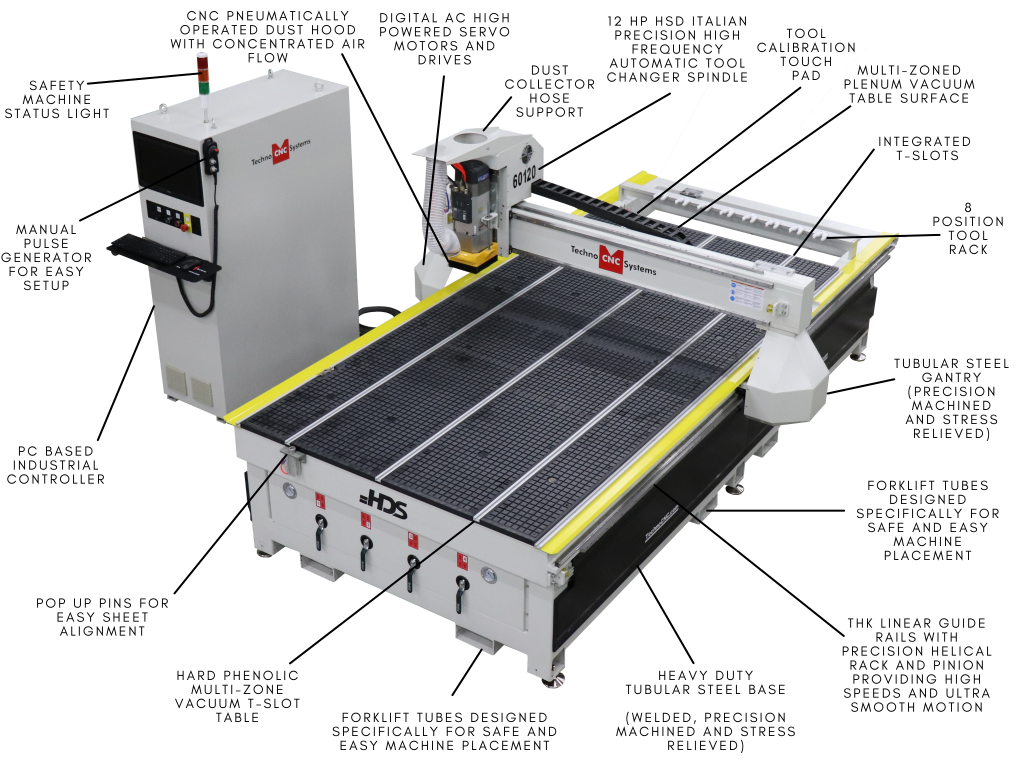

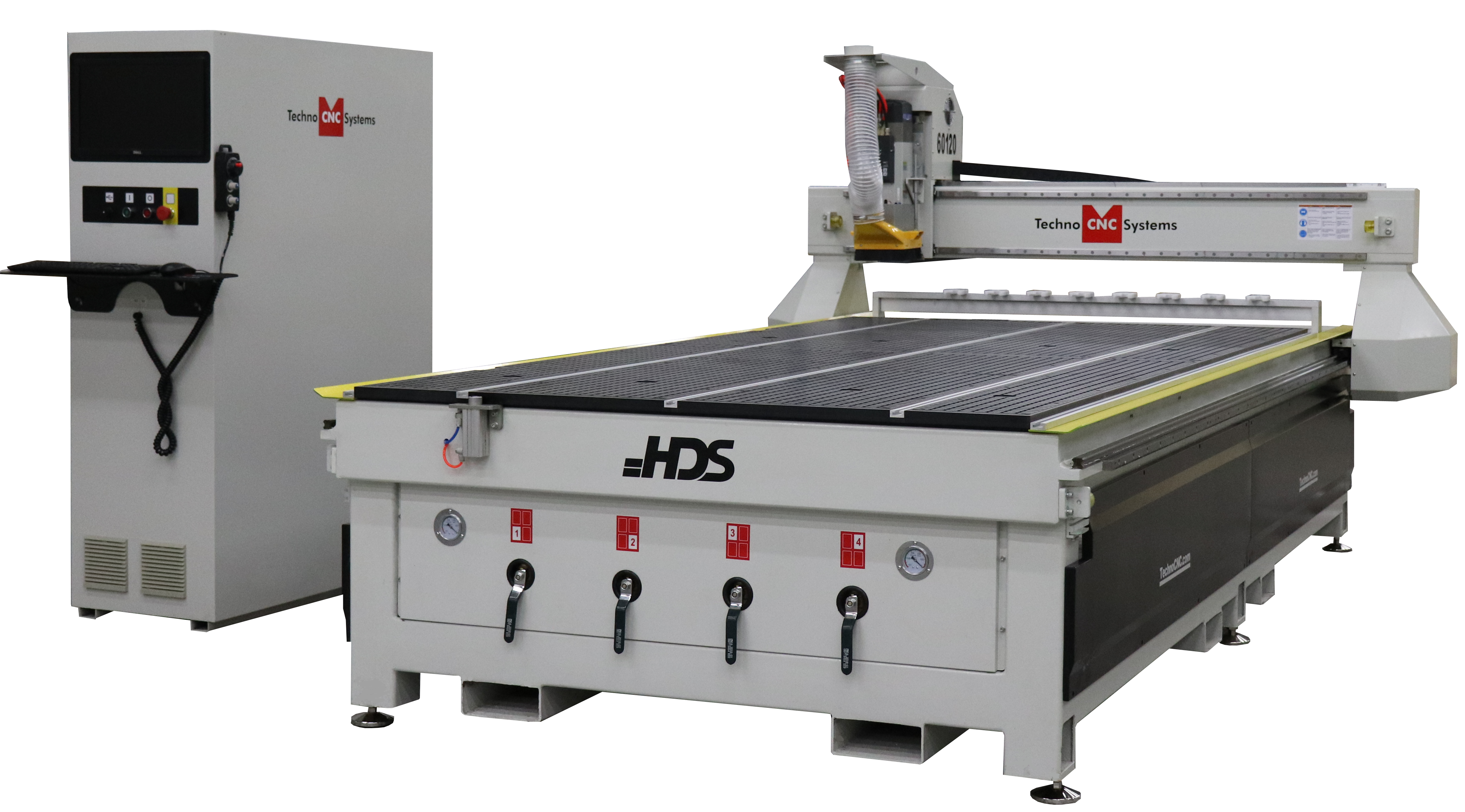

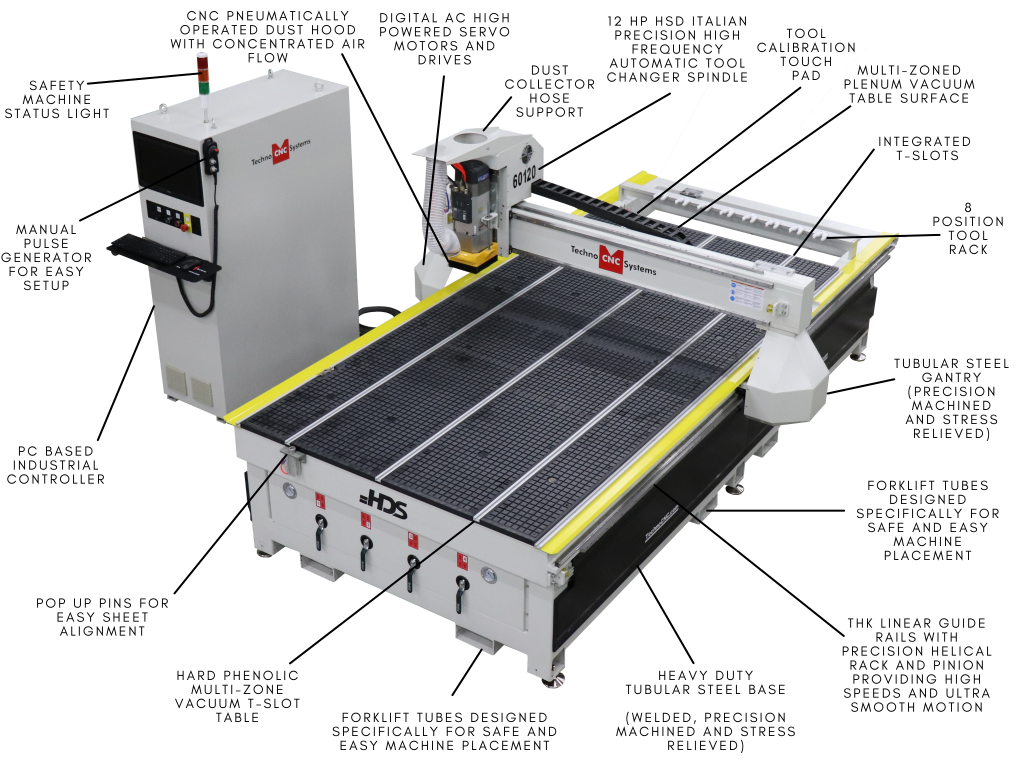

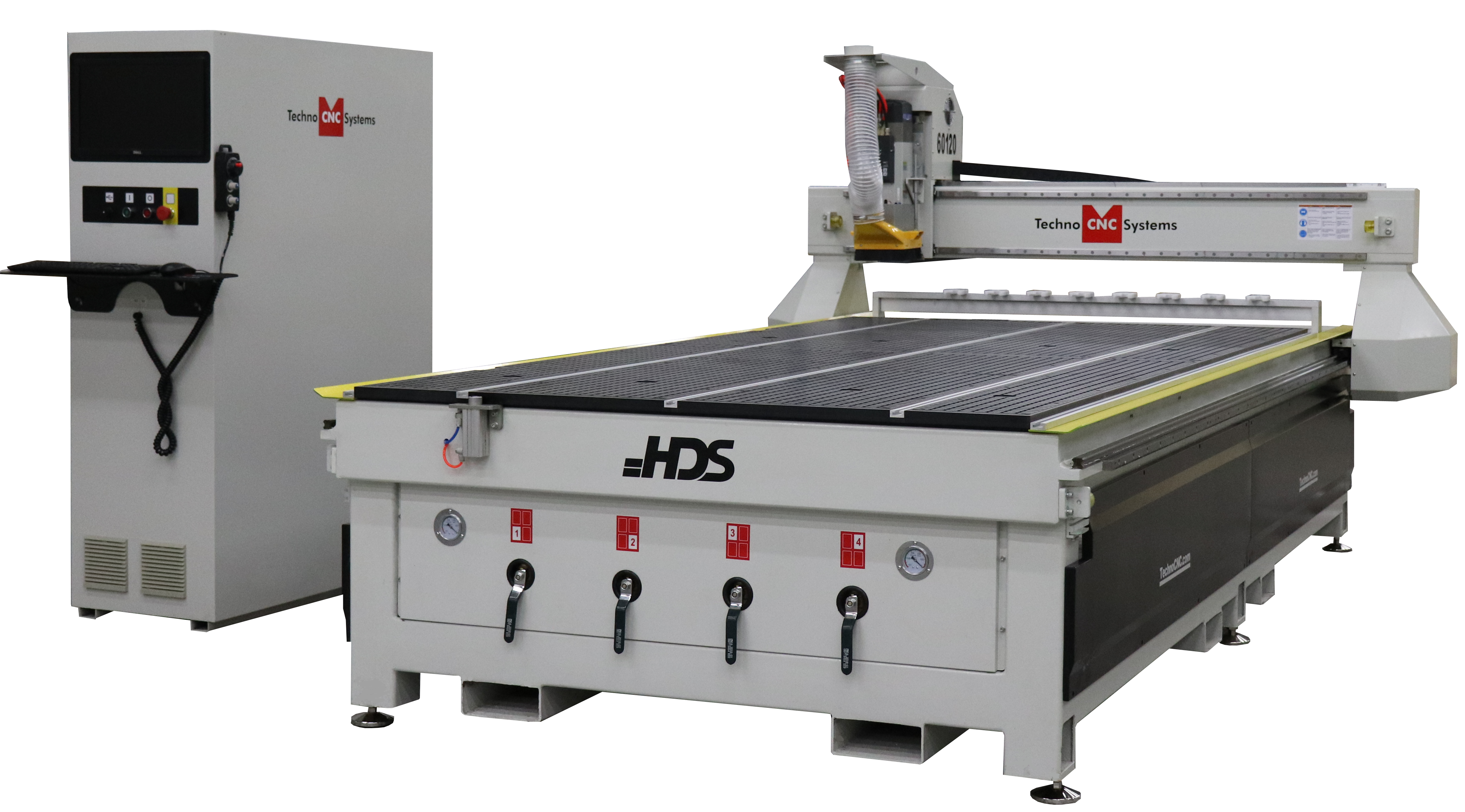

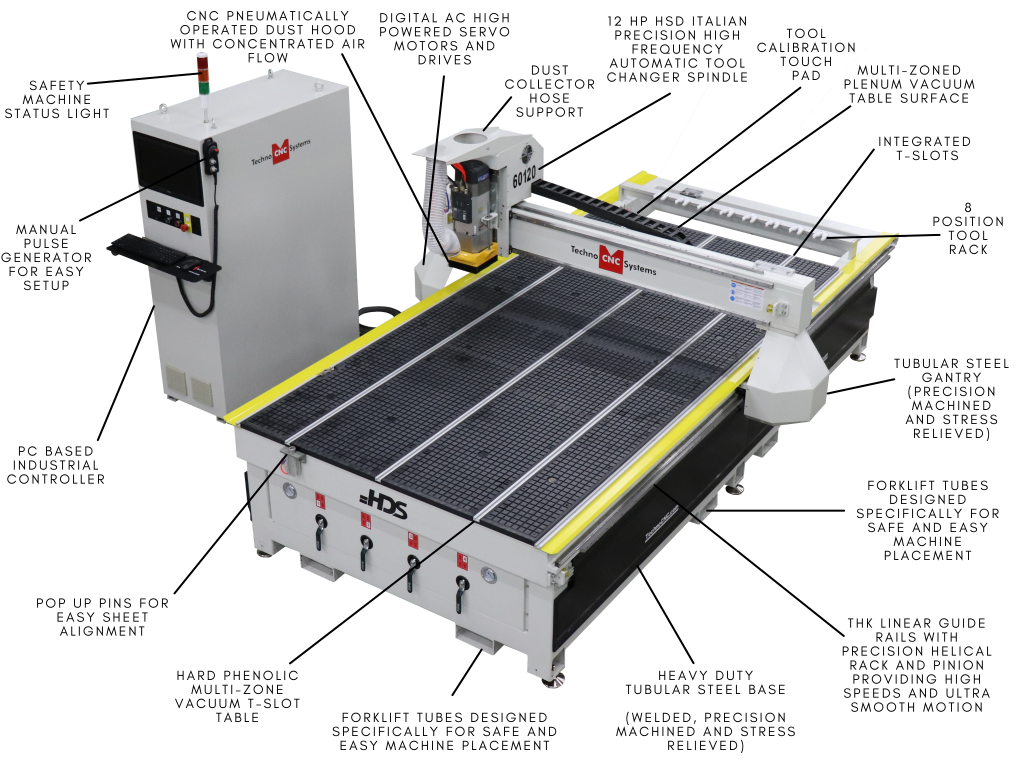

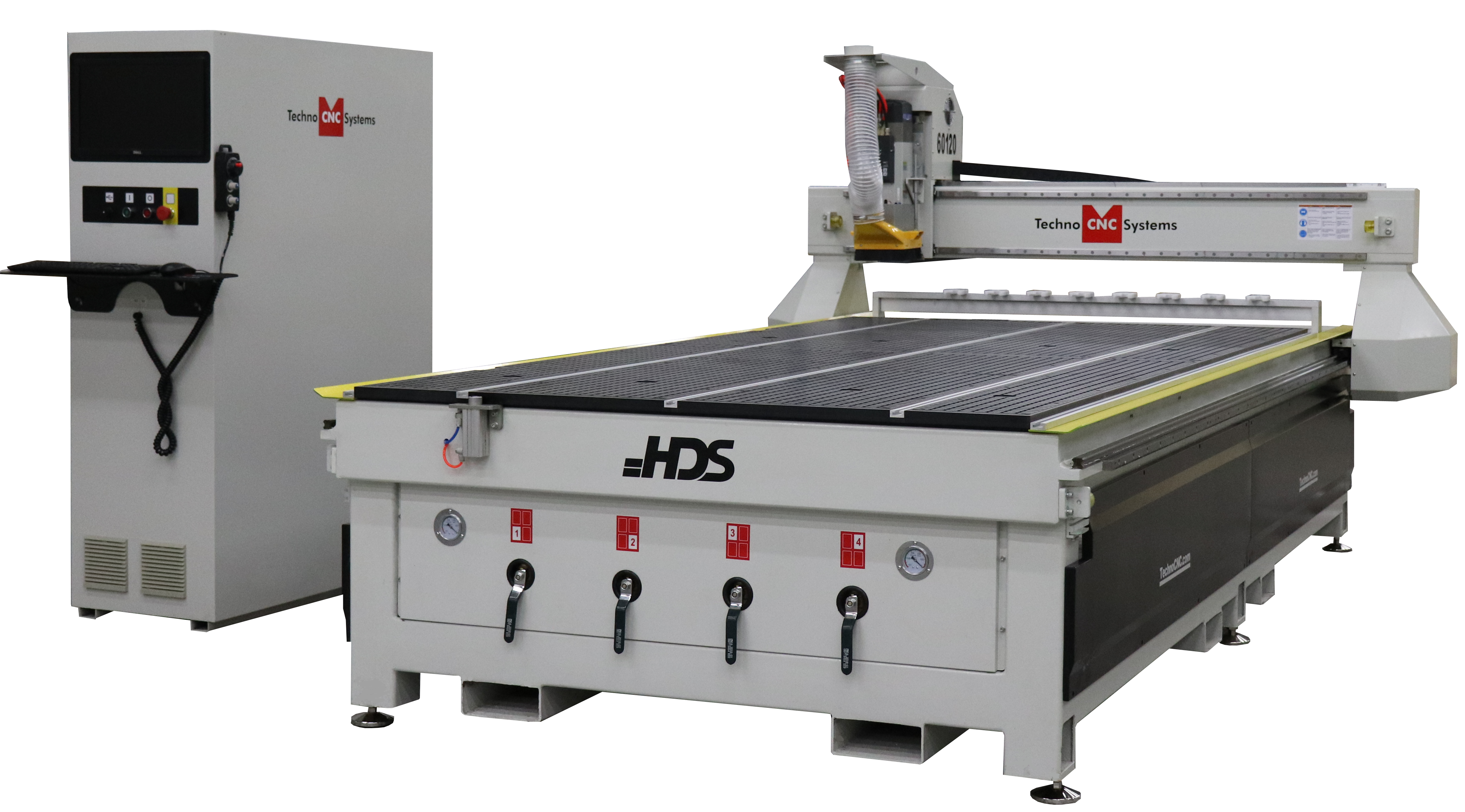

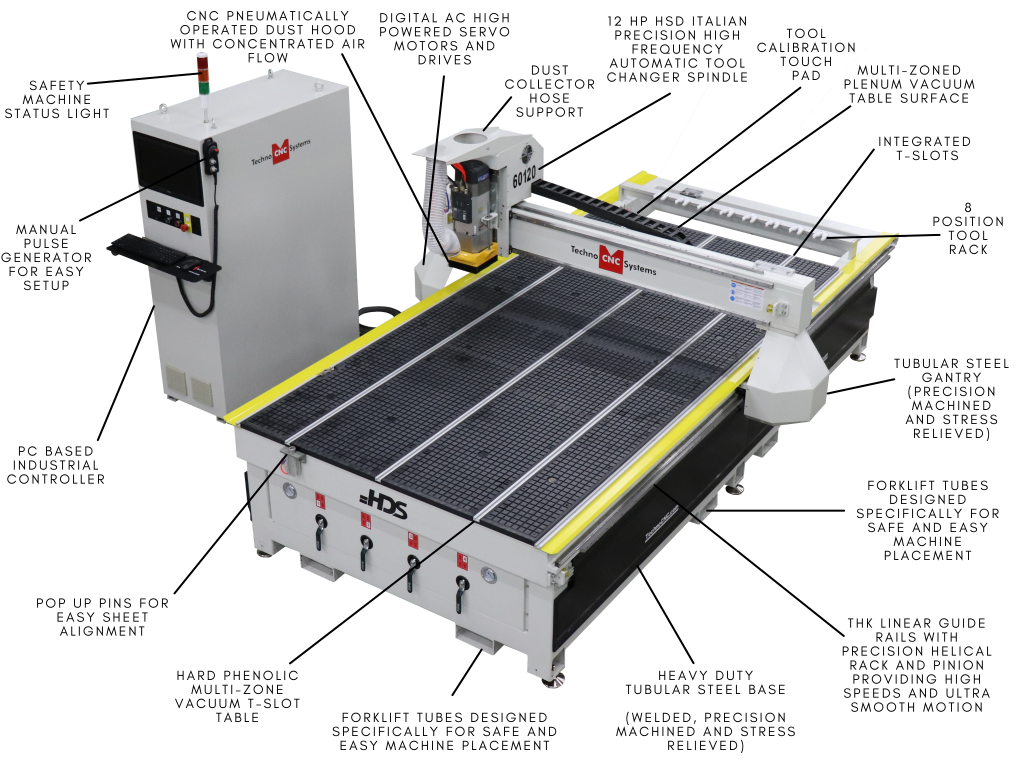

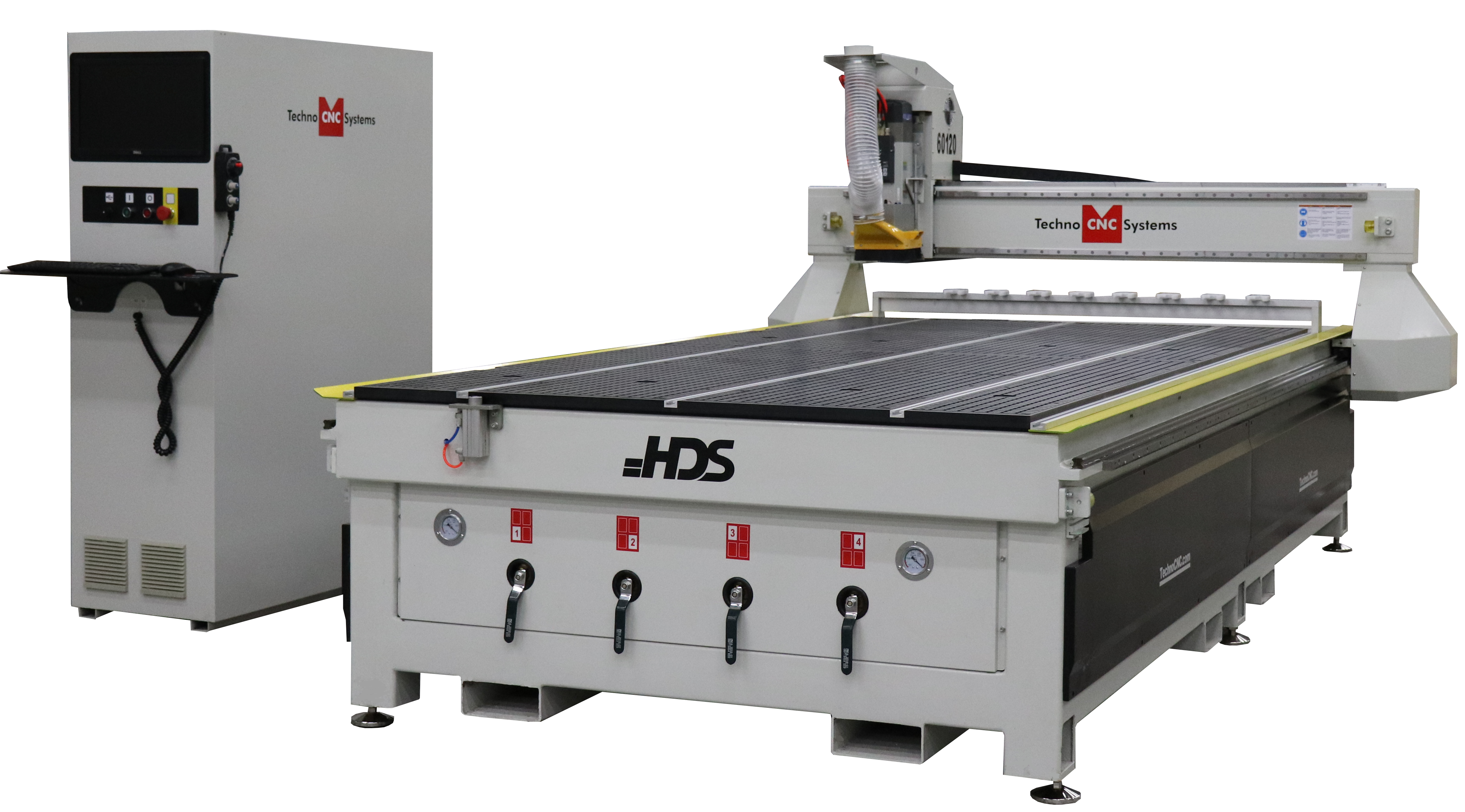

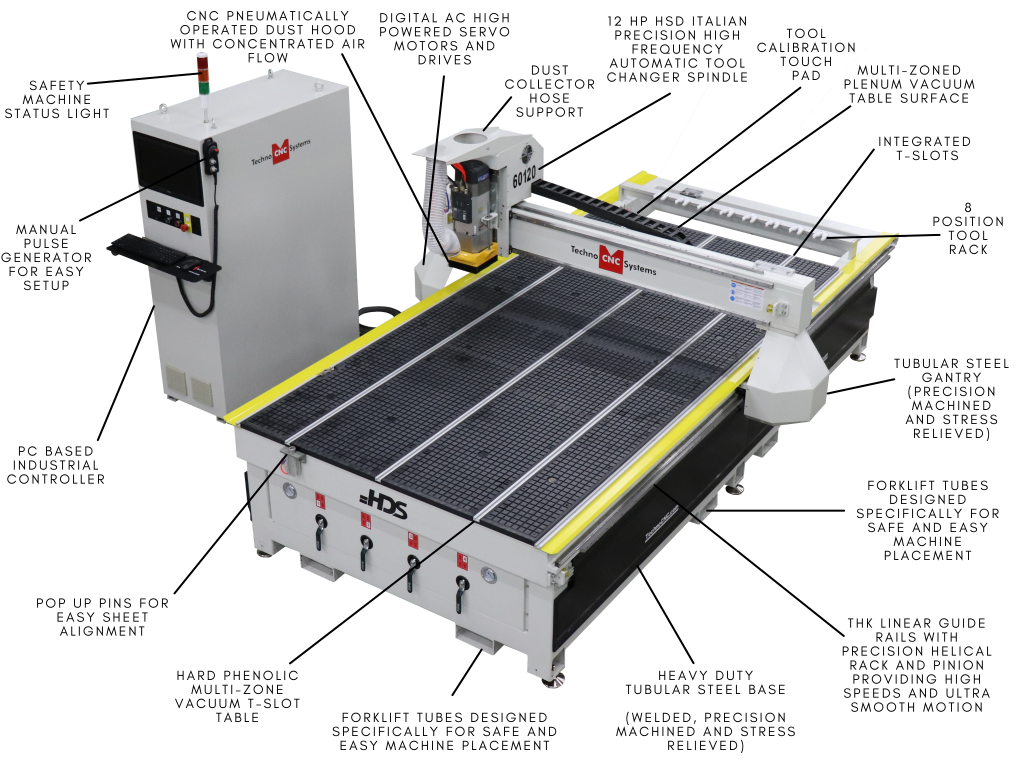

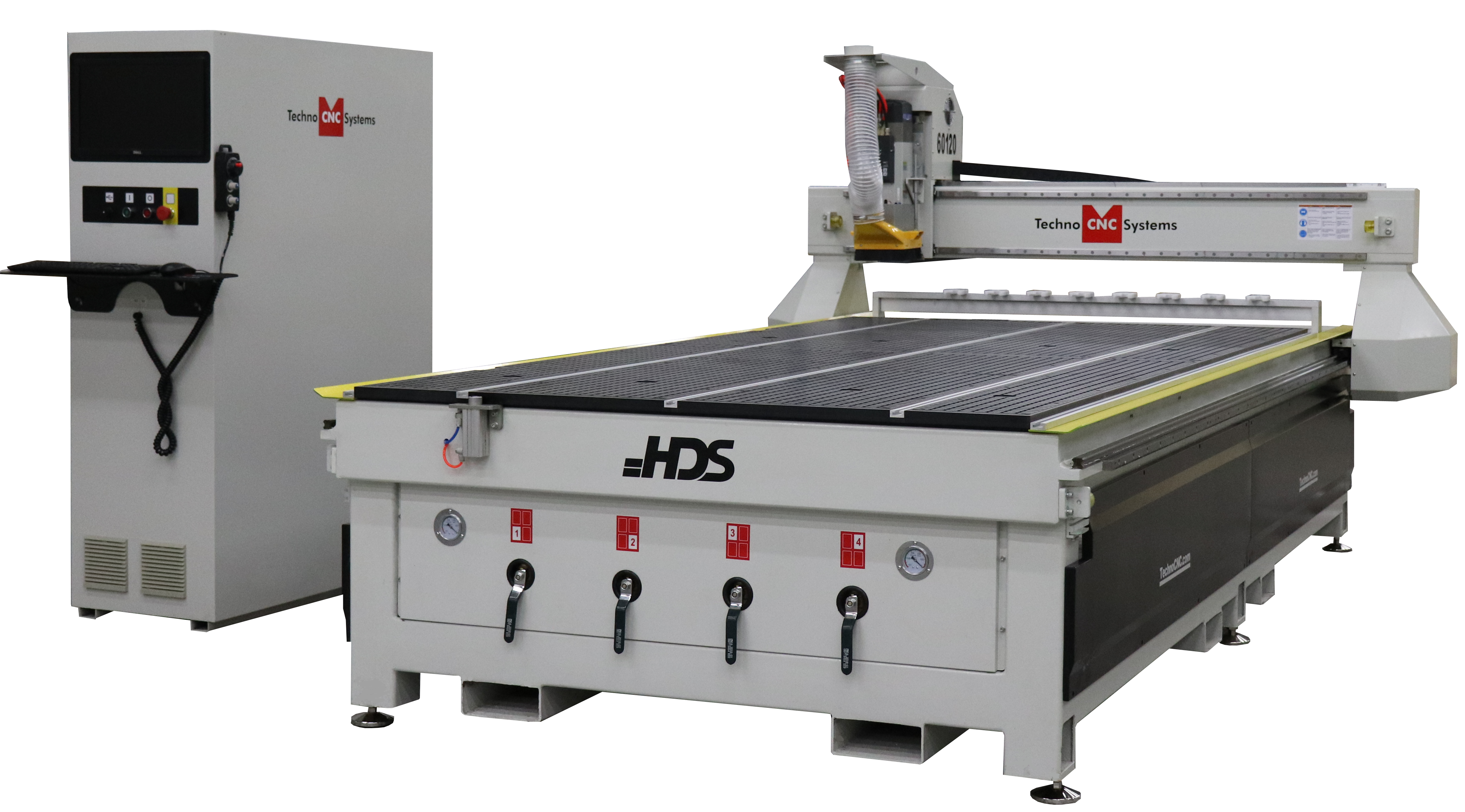

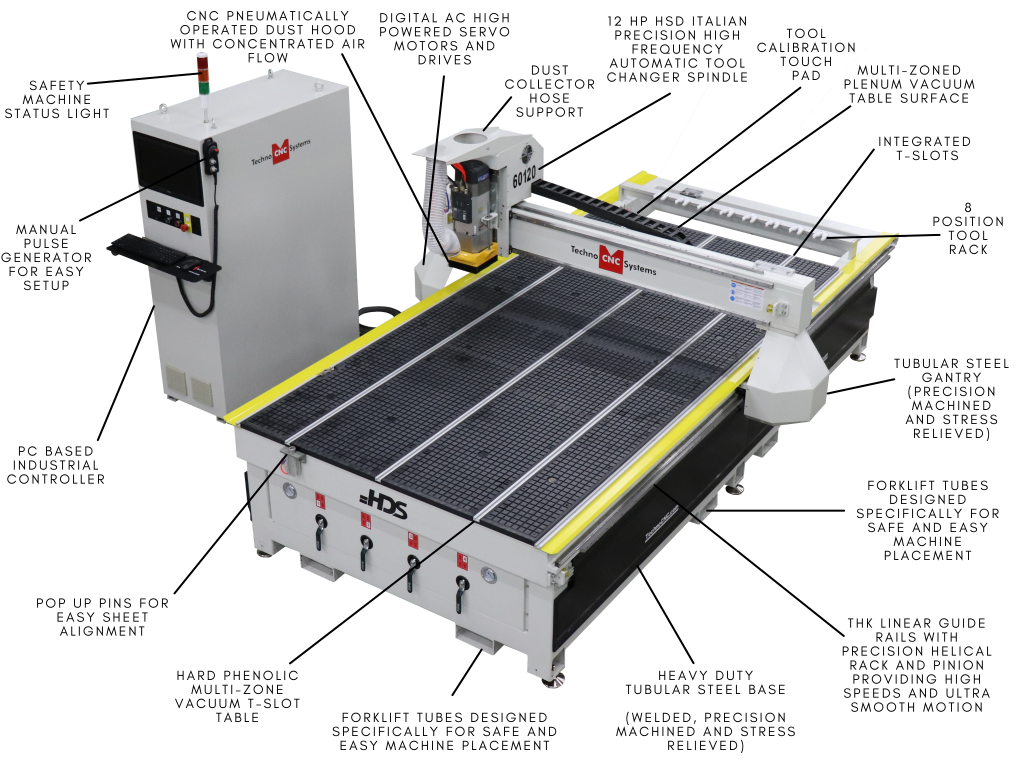

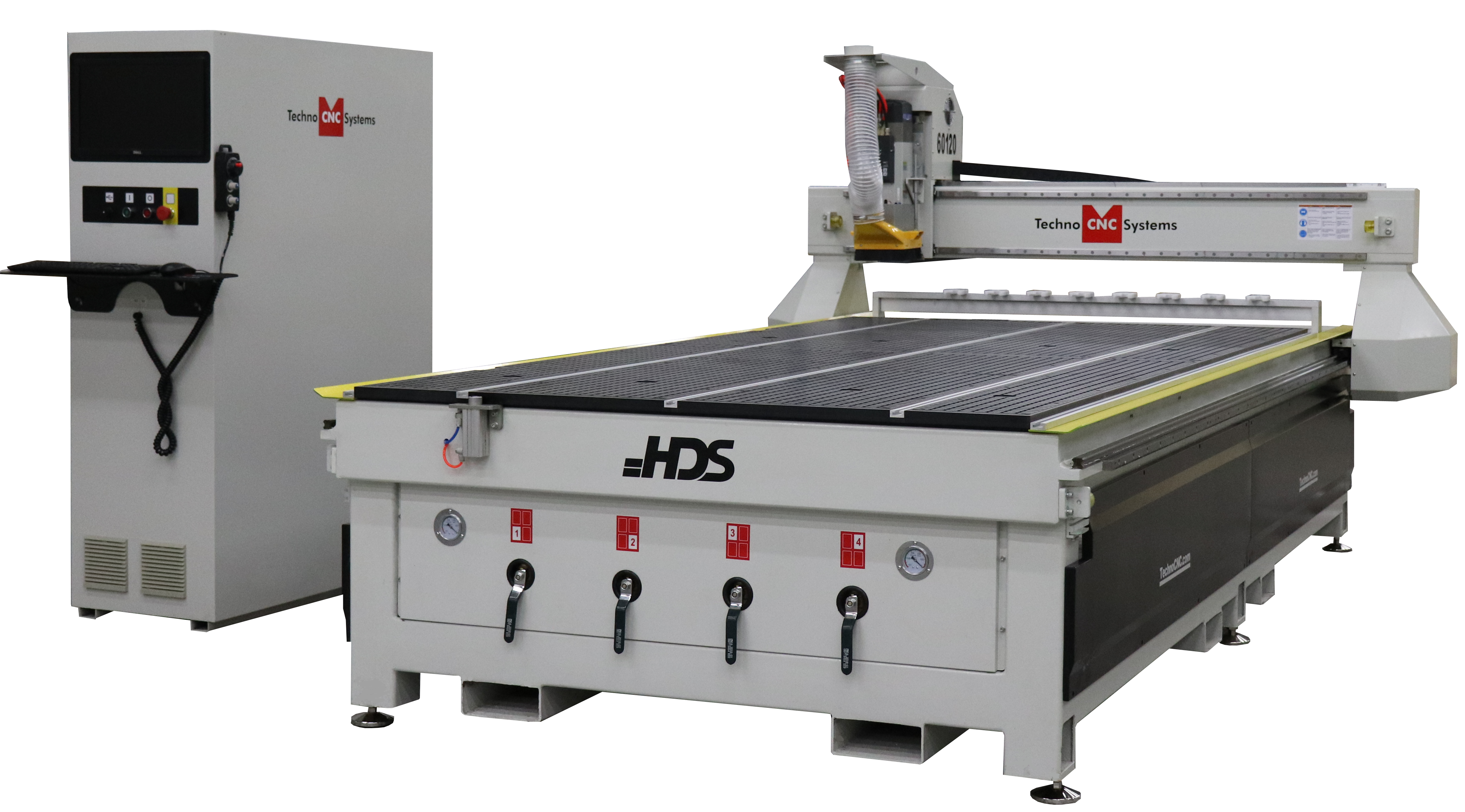

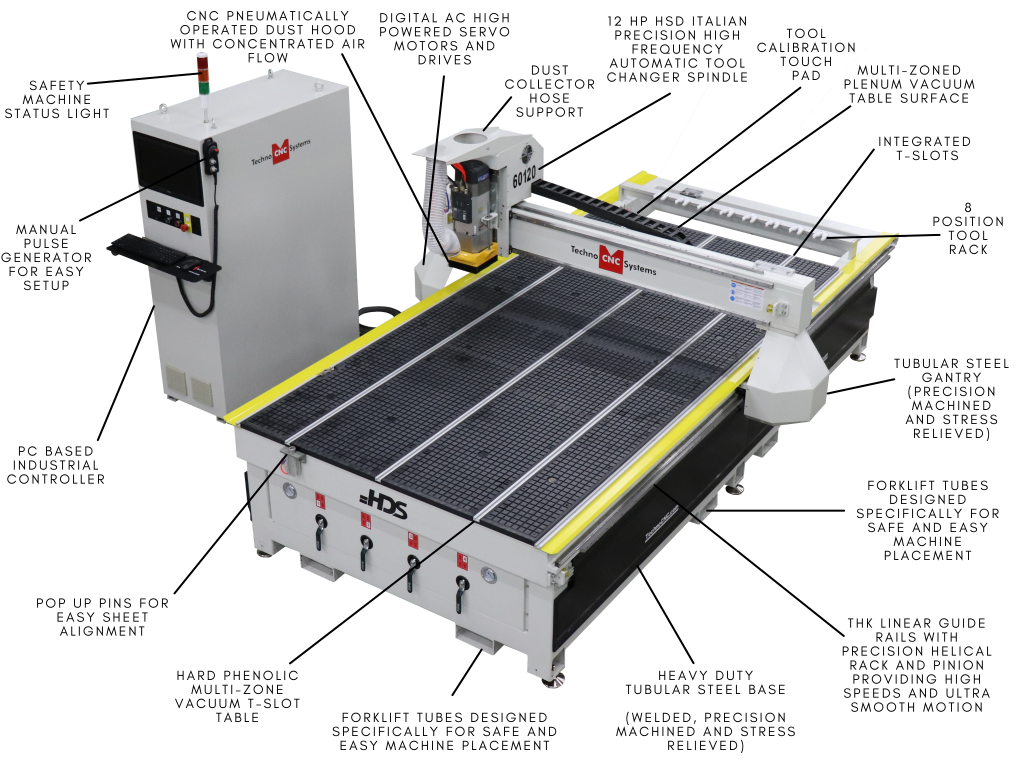

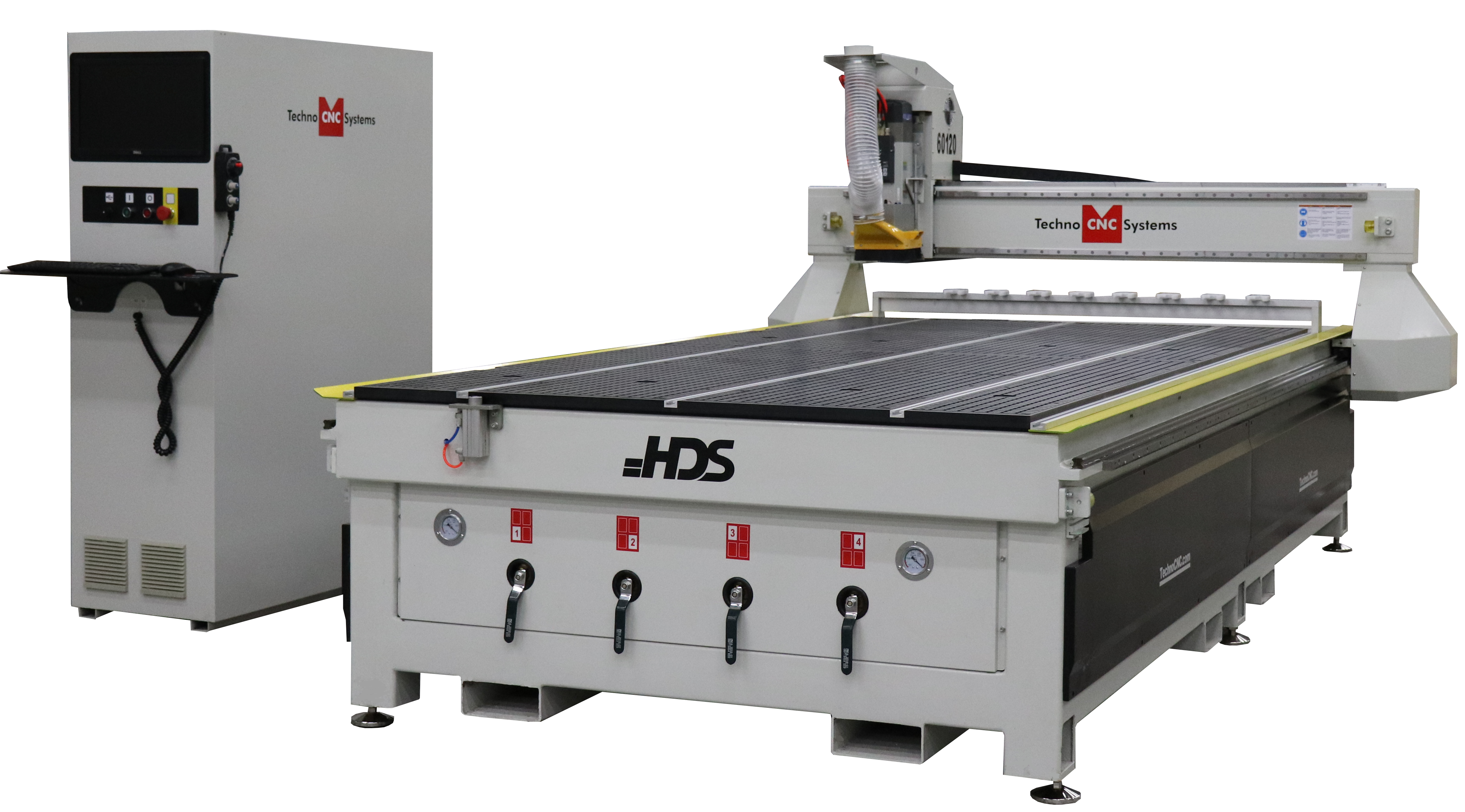

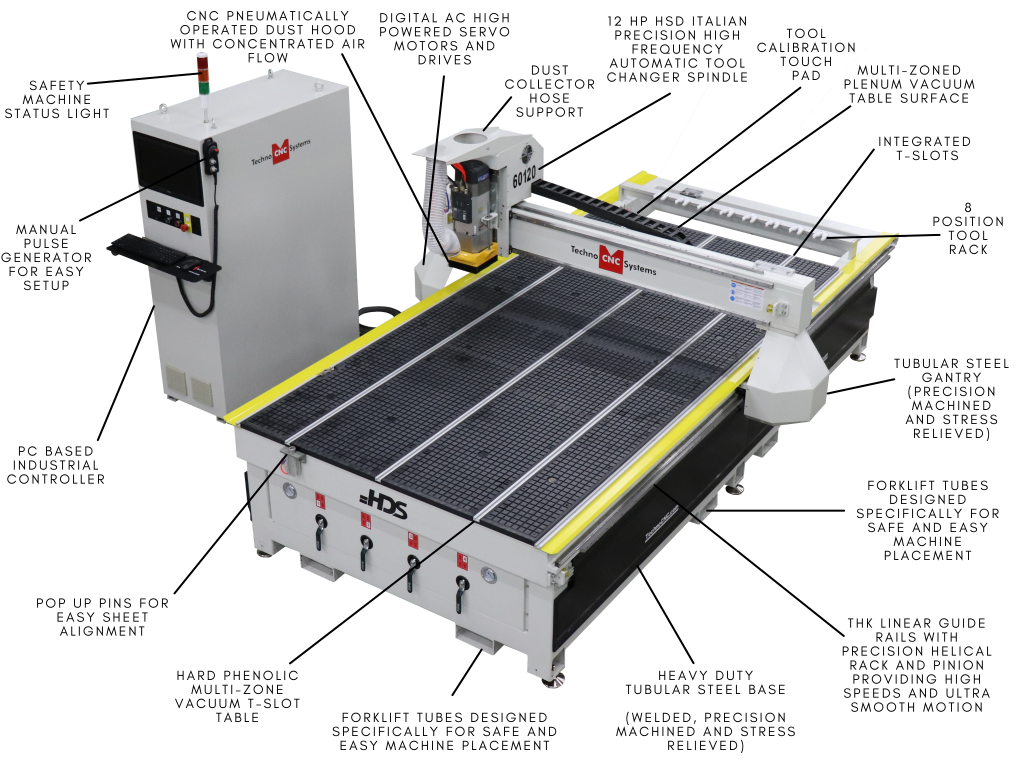

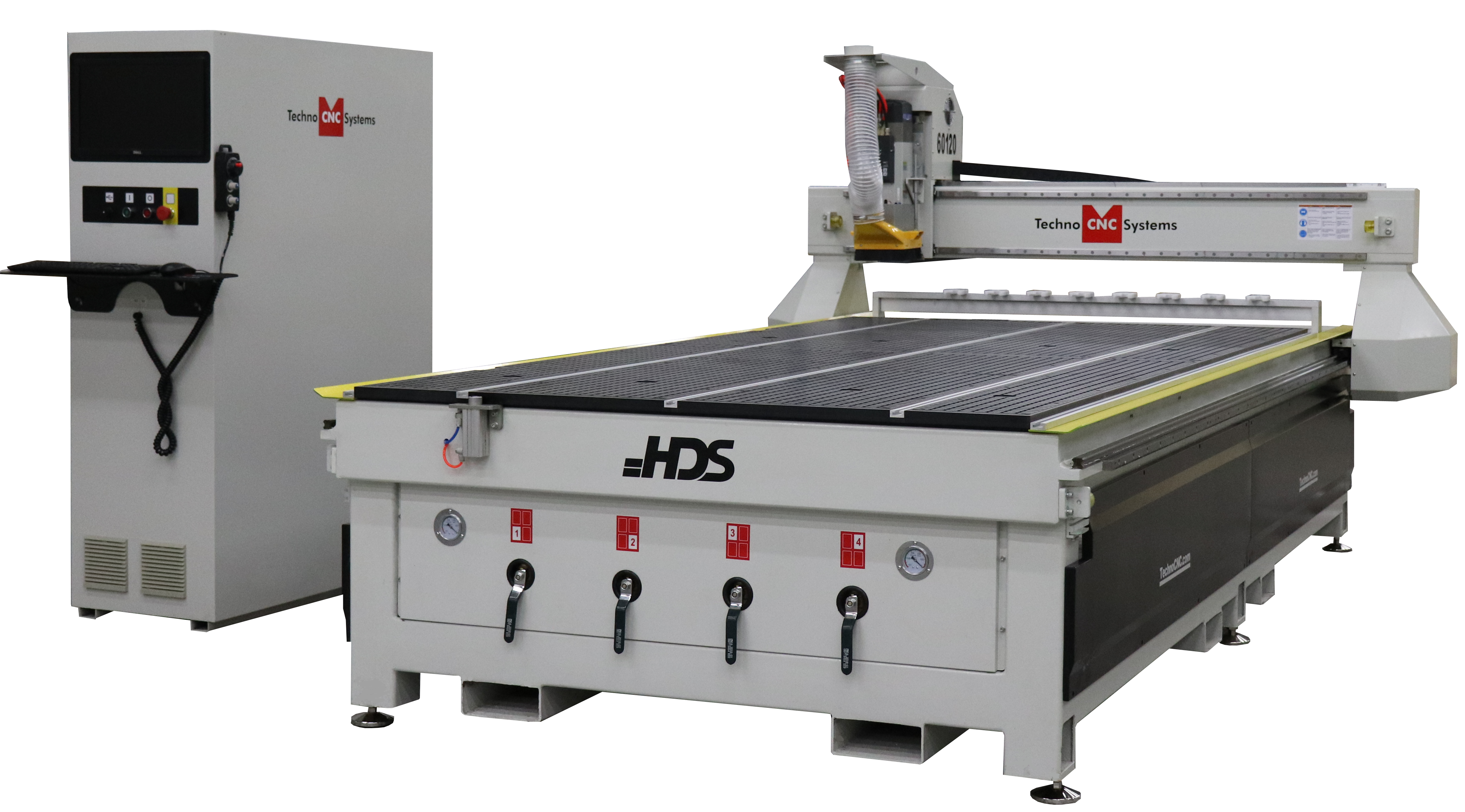

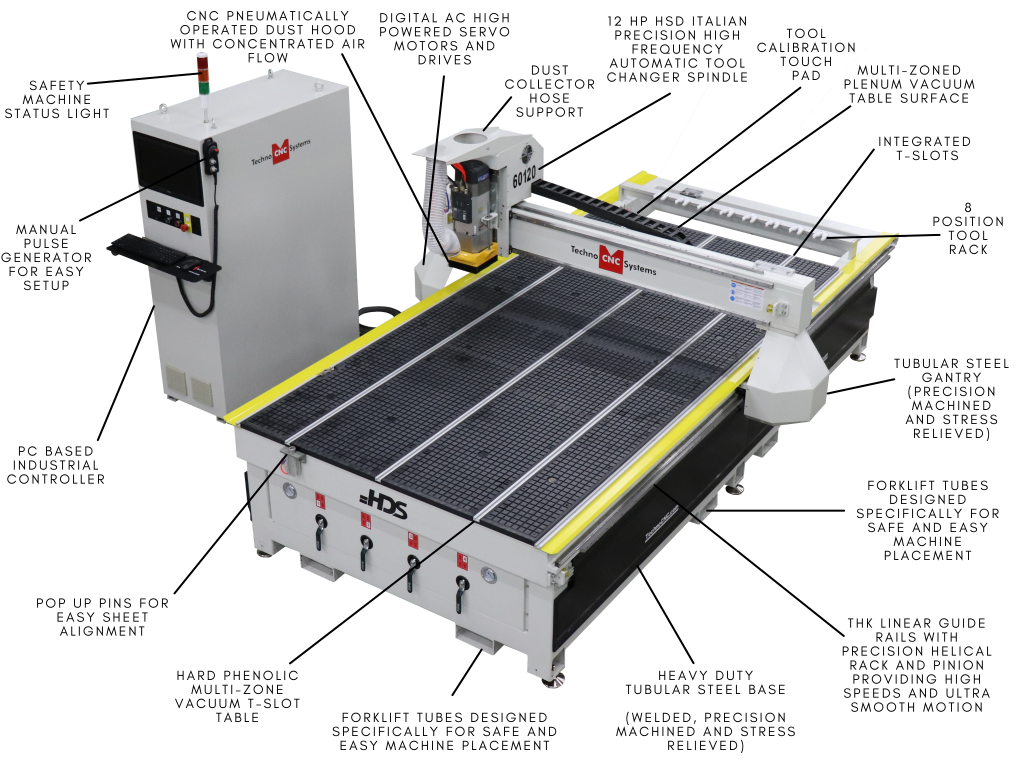

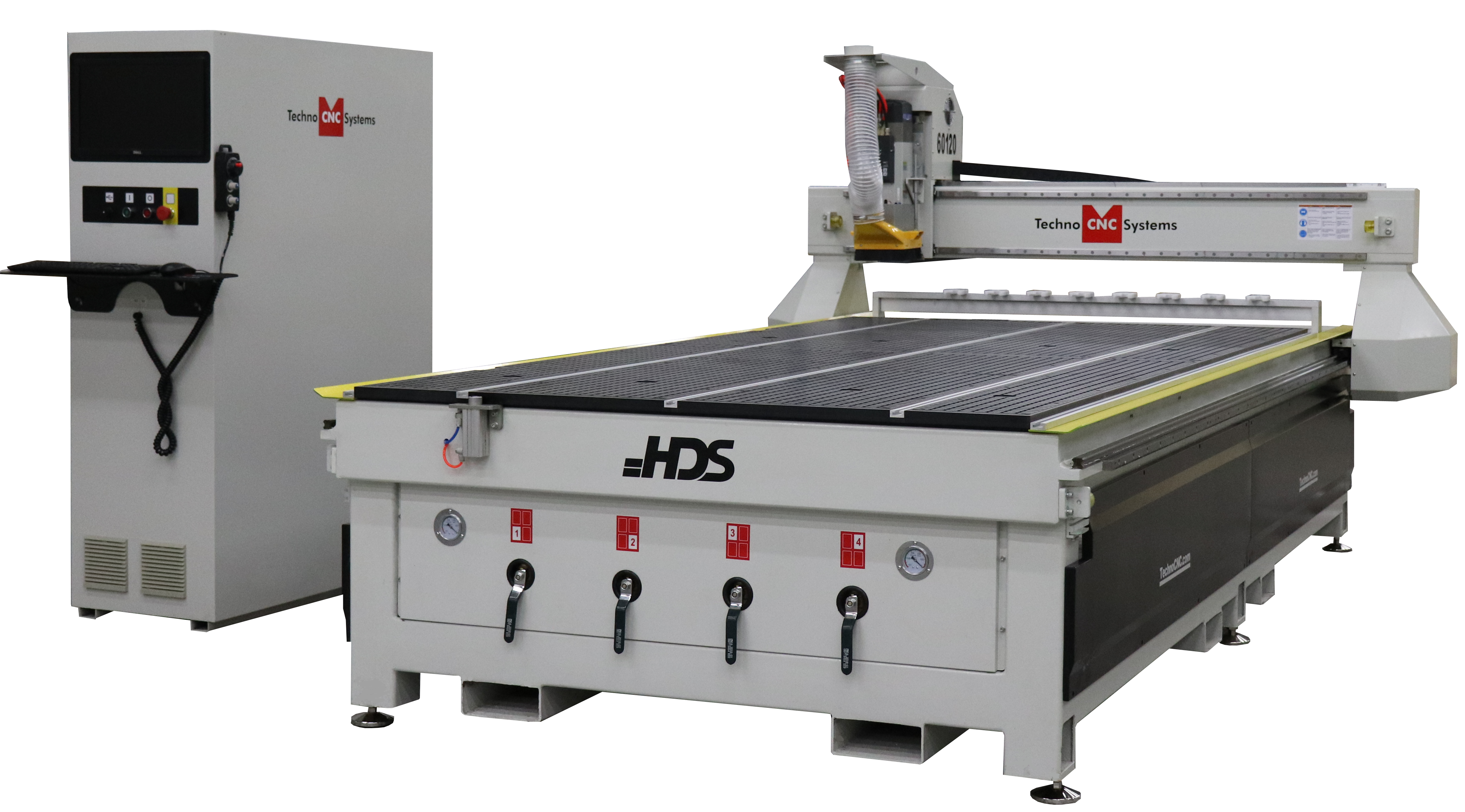

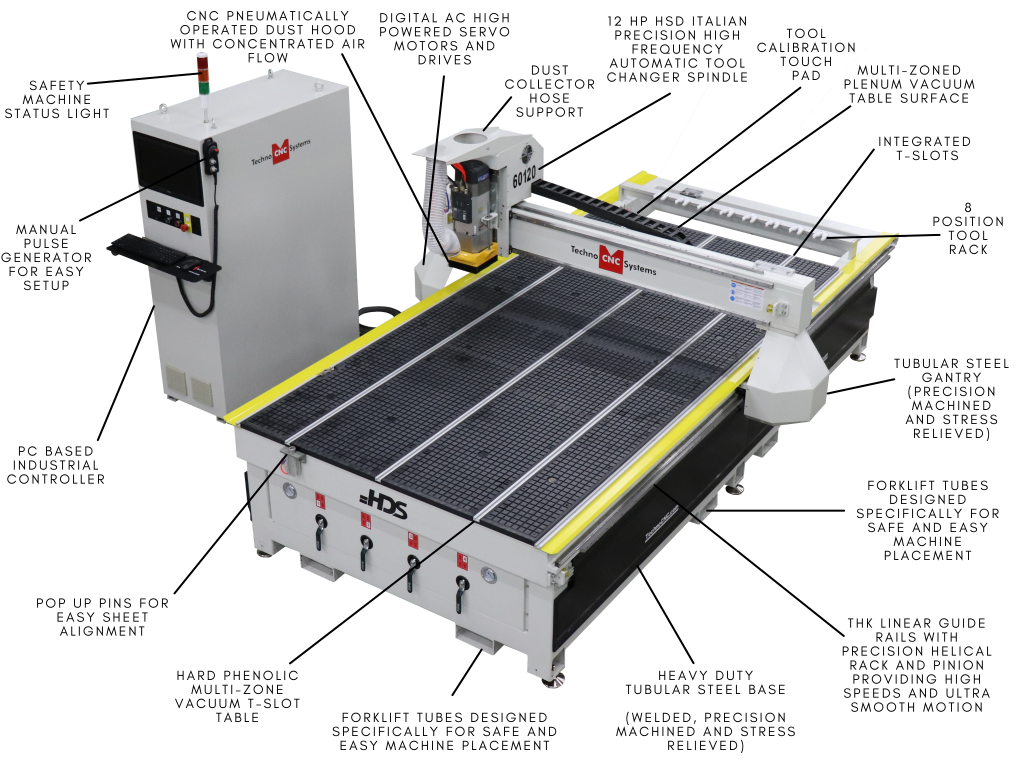

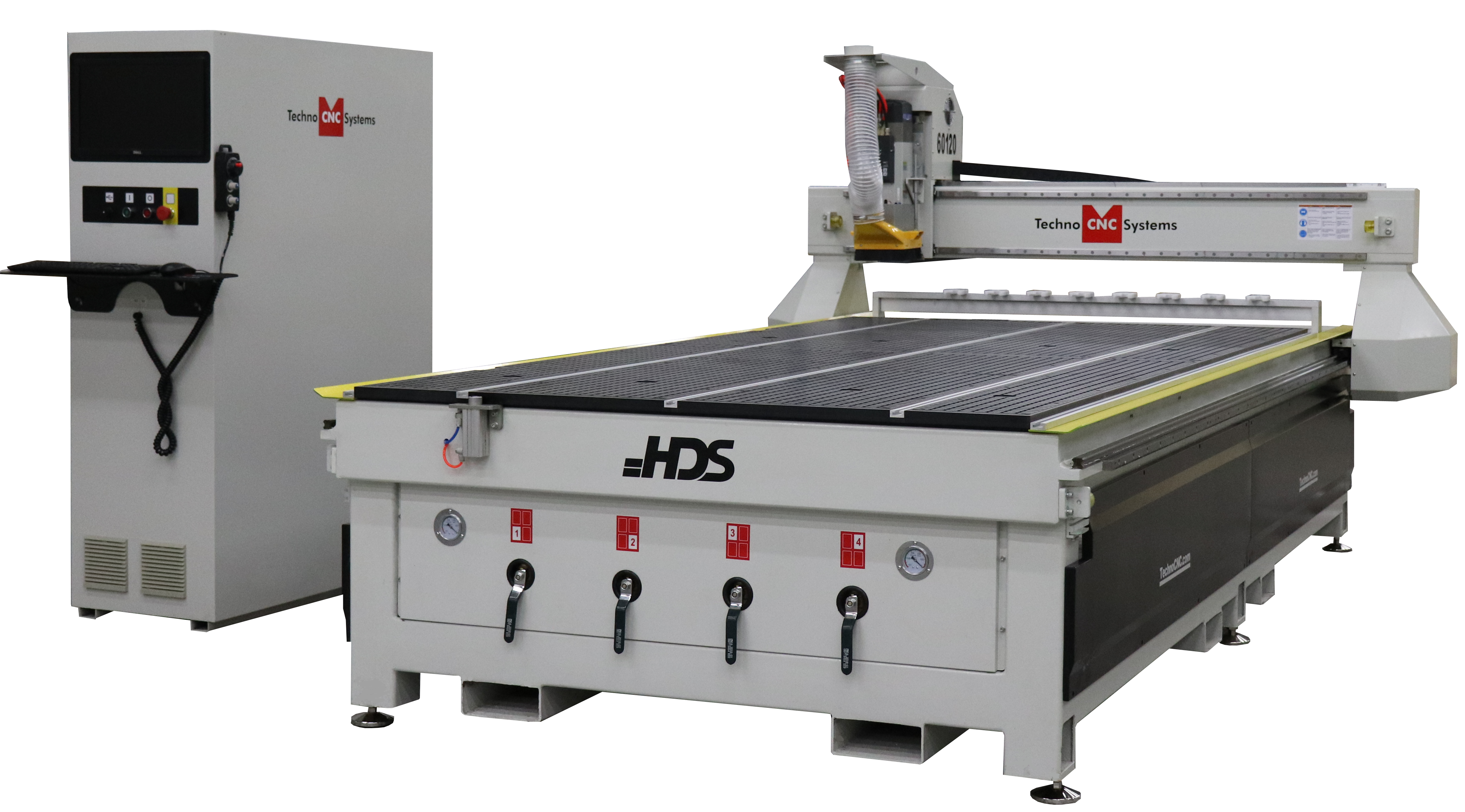

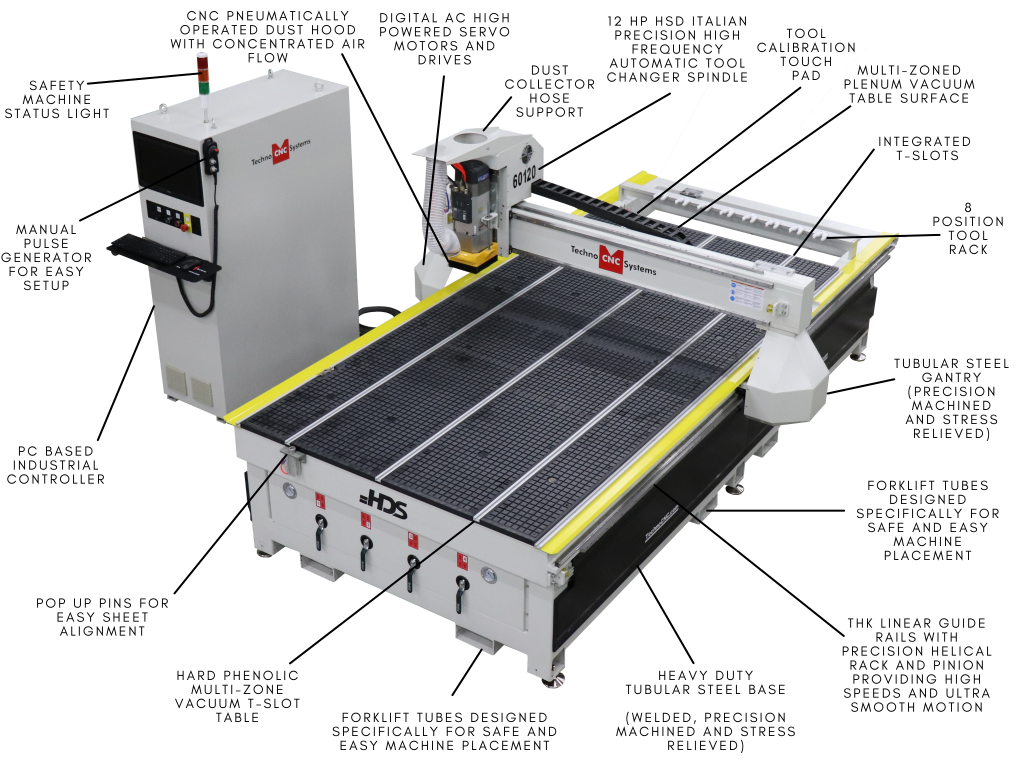

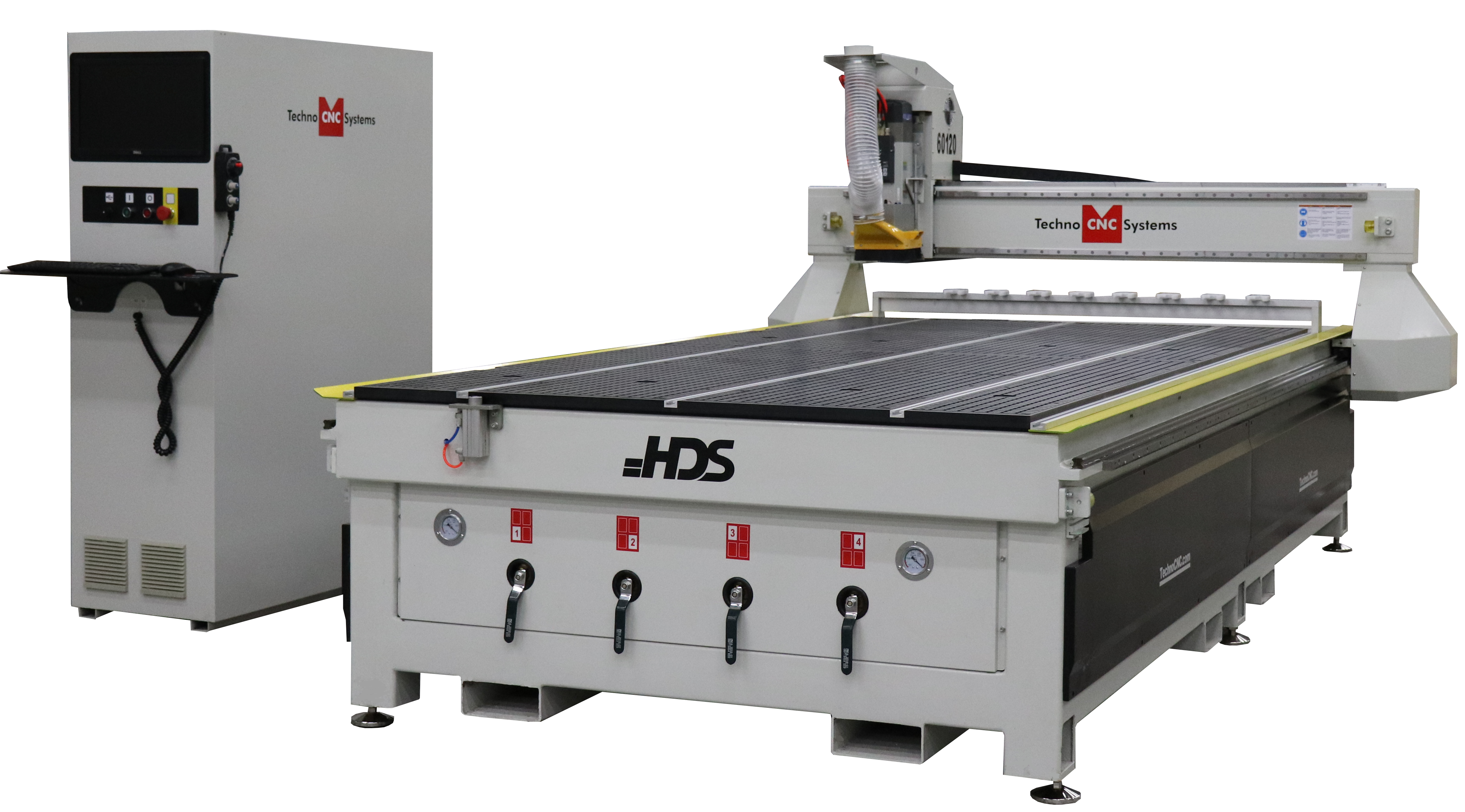

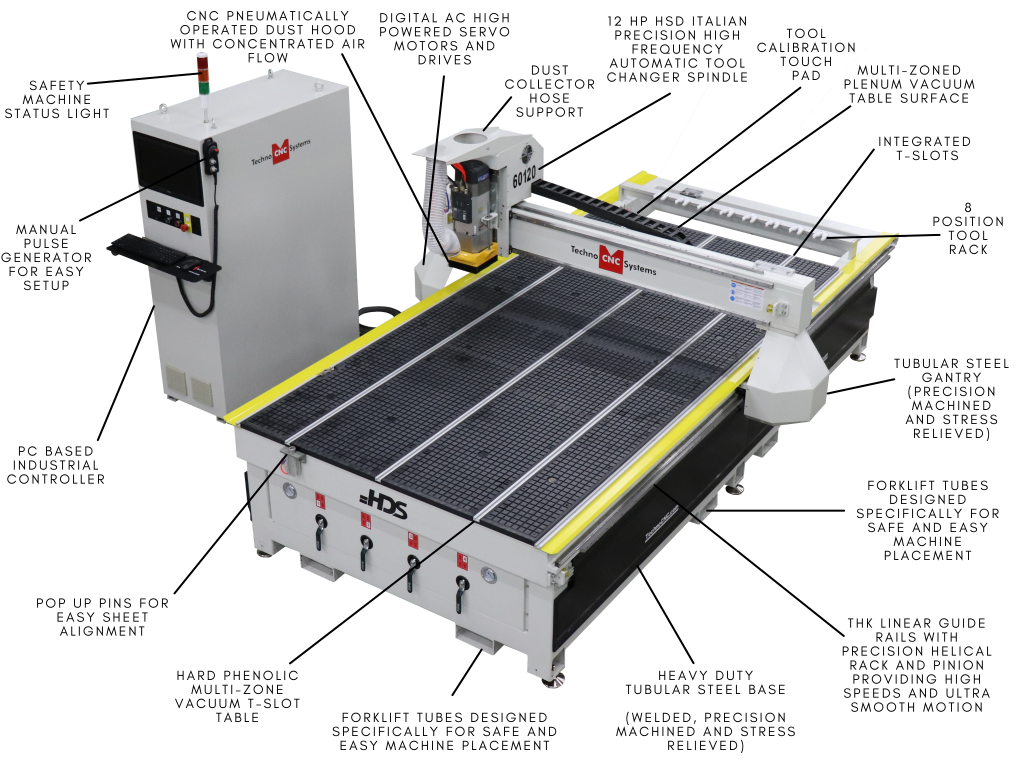

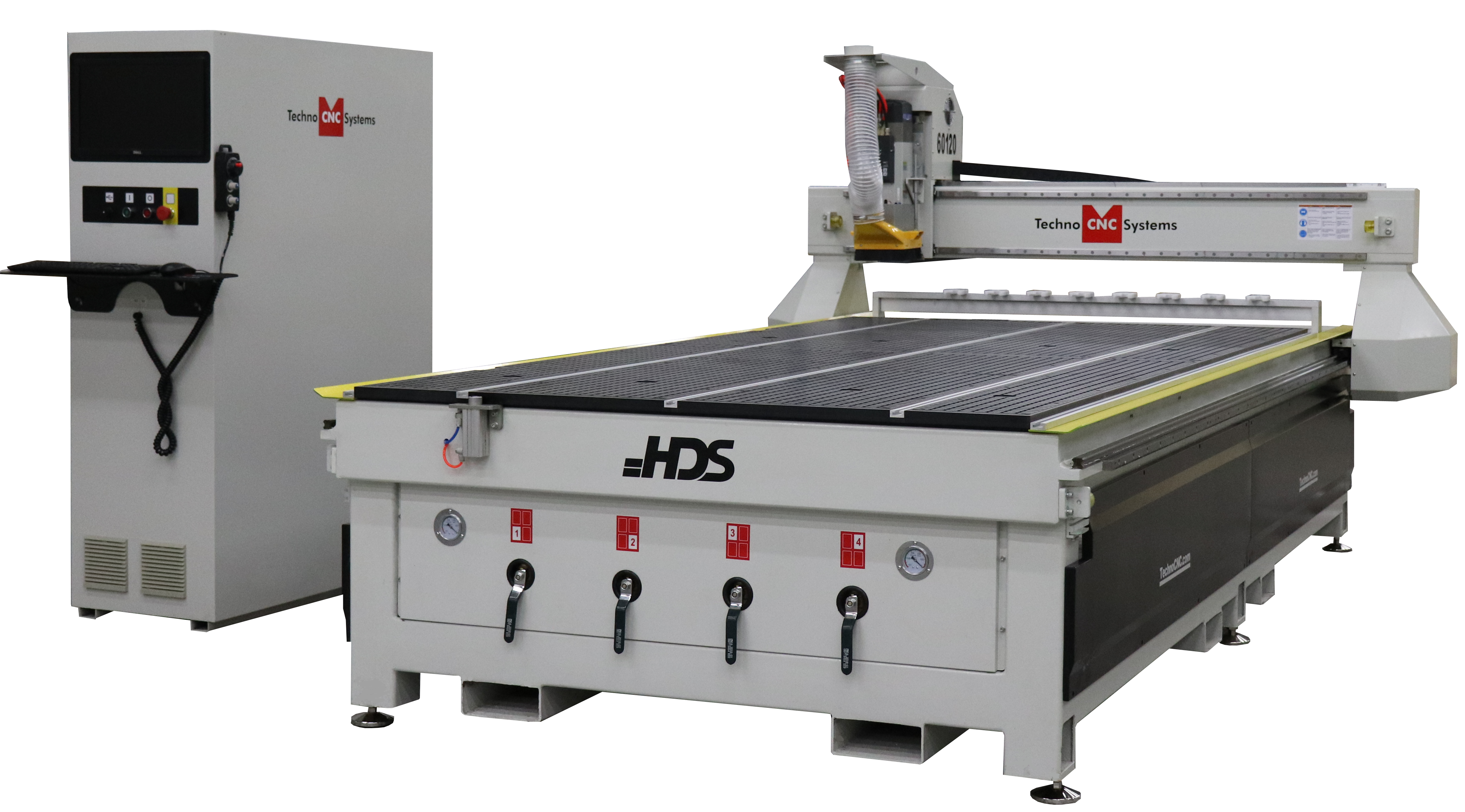

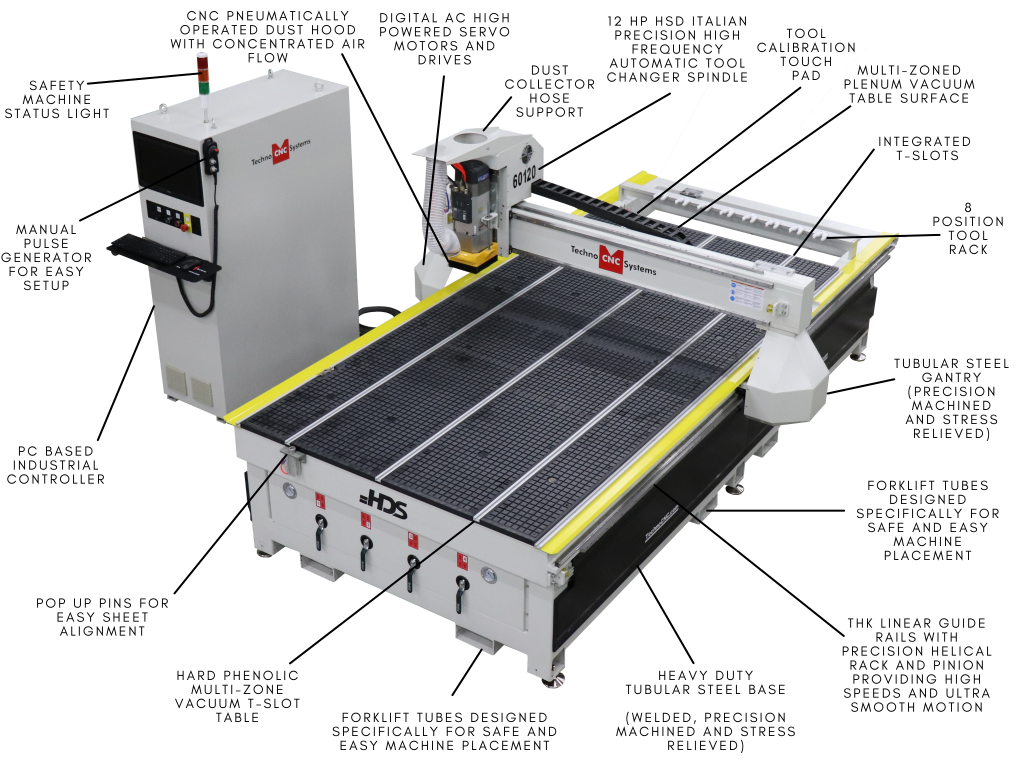

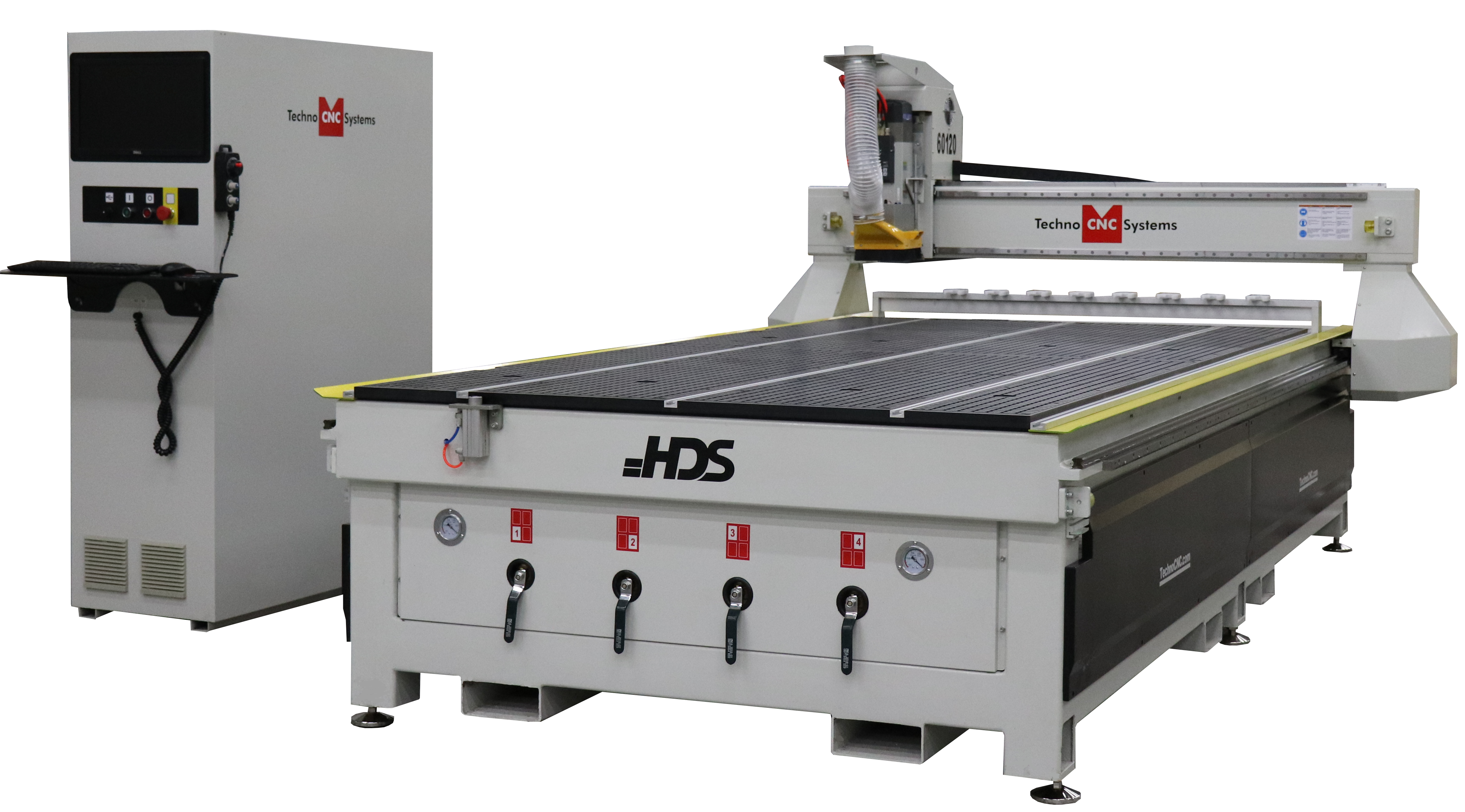

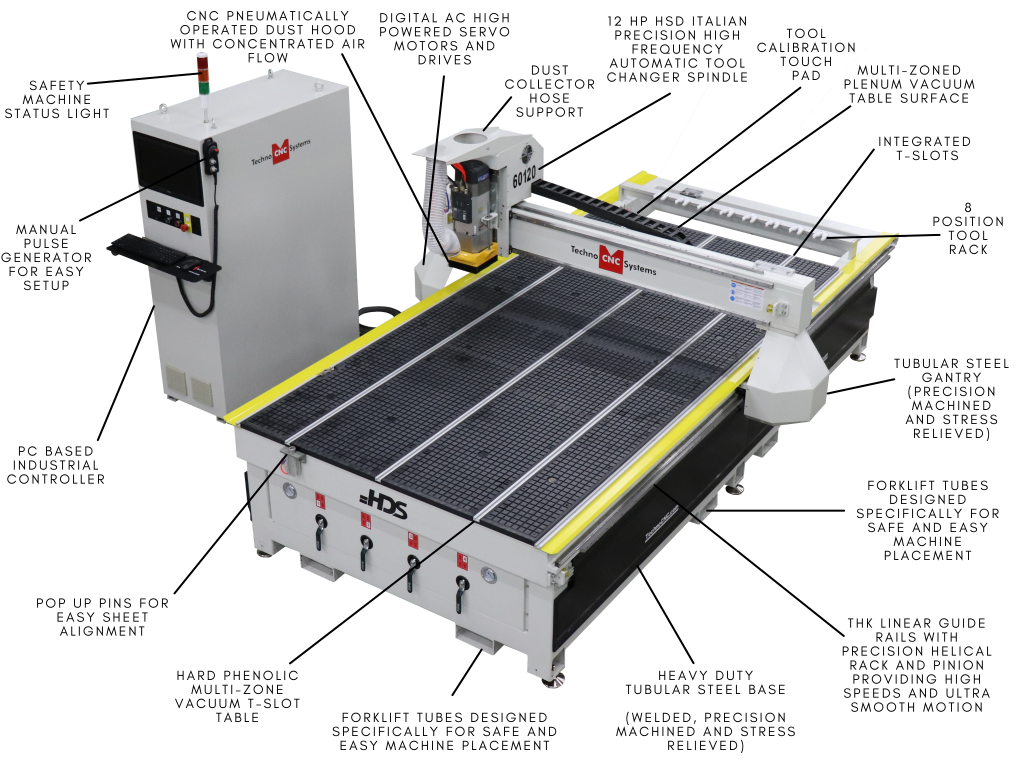

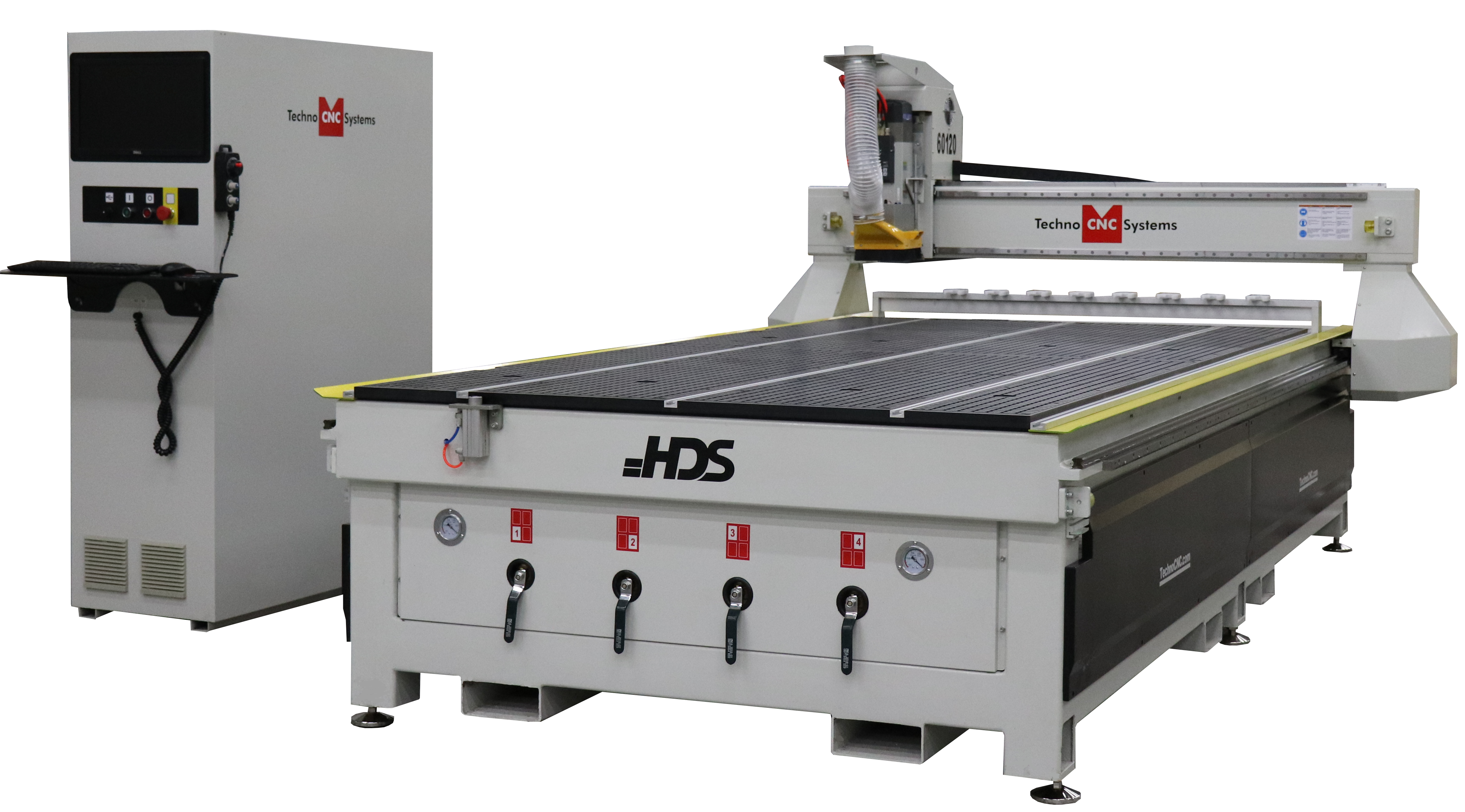

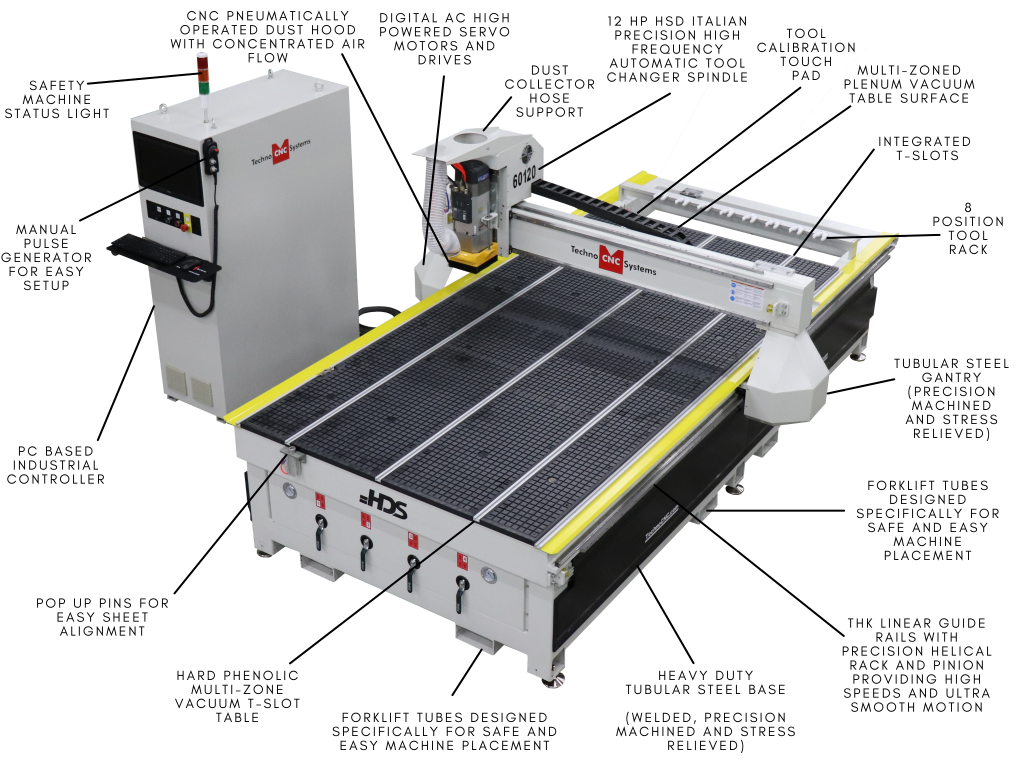

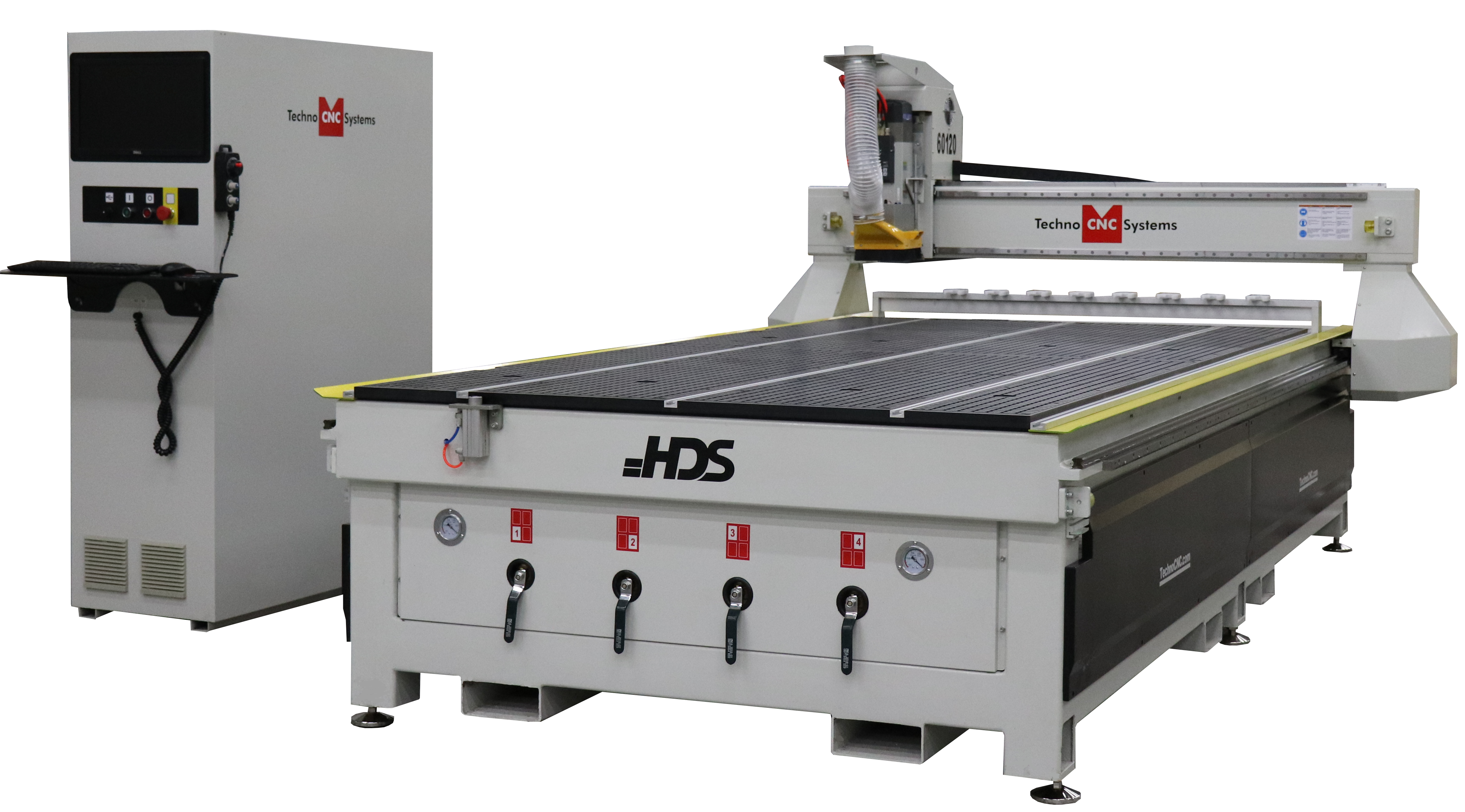

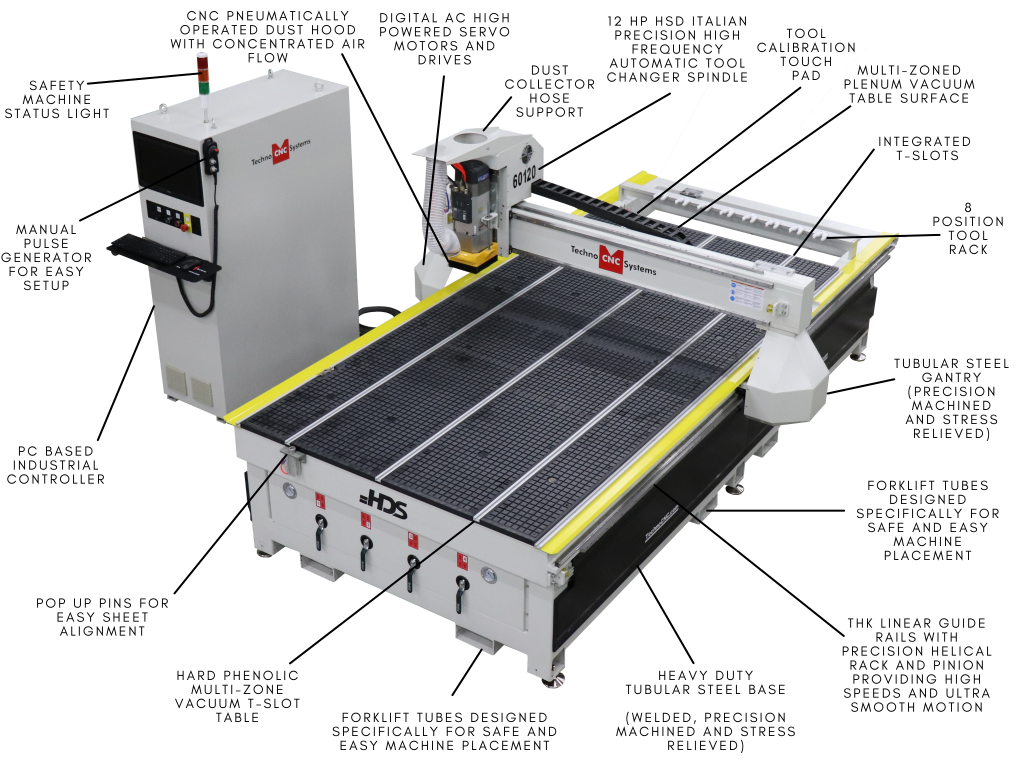

Techno’s HDS Series CNC Machine is made up of all steel construction, providing the rigid foundation required for ultra-smooth routing results. The HDS Series CNC Router includes a 12 HP HSD automatic tool changer spindle with an 8-position tool rack, and comes standard with a pneumatically operated dust collection hood that concentrates air flow at the cutter, providing optimal dust collection performance. The multi-zone vacuum t-slot table is constructed from very hard Phenolic; an extremely stable material that holds tight tolerances for precision cutting. This CNC machine is connected to a 10HP rotary vane vacuum pump (twin pack optional), for quiet operation. For easy sheet alignment, (3) pop-up pins are included on the HDS Series, and are precisely placed to handle and align various size materials. The HDS Series CNC Machine is powered by brushless AC Servo digital motors and drives, and is powered by an easy-to-use and learn Osai PC based industrial controller.

Featured List

All steel construction

12 HP HSD high frequency automatic tool changer spindle

4-Zone vacuum t-slot table

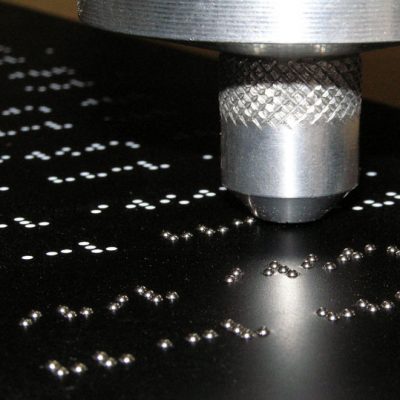

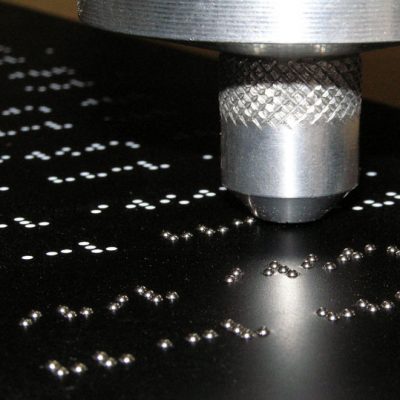

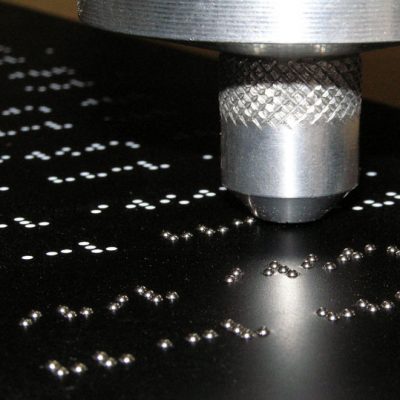

Material pop-up pins for easy sheet alignment

Osai PC based Industrial grade CNC controller

Brushless digital AC servo motors and drives

Features

Steel Base

The HDS Series base frame is fabricated from heavy-duty tubular steel that is welded, precision machined and stress relieved so that the foundation remains true and steady over the operational life of the machine.

Gantry

The gantry is constructed of tubular steel with reinforcing ribs welded throughout the length of the column which results in a steady firm beam assembly. This quality engineering and workmanship result in smooth precision cutting.

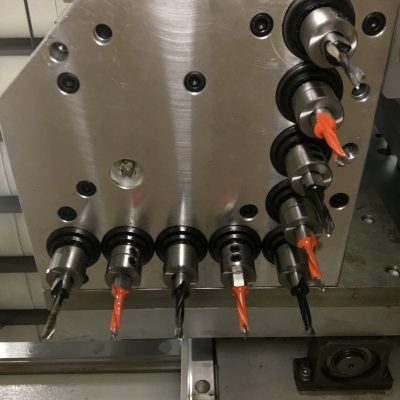

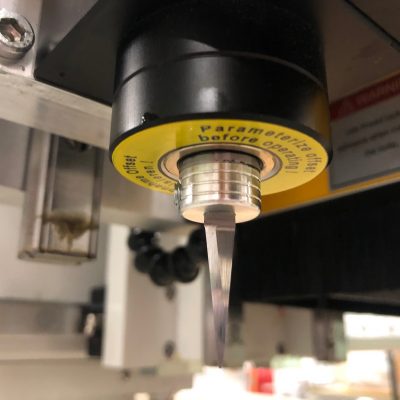

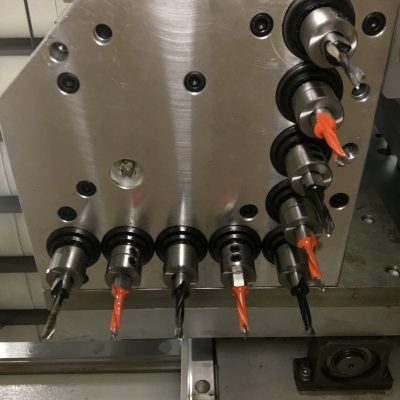

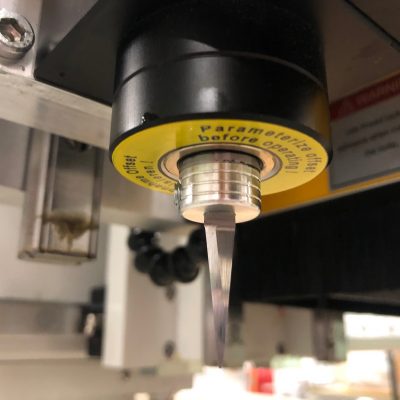

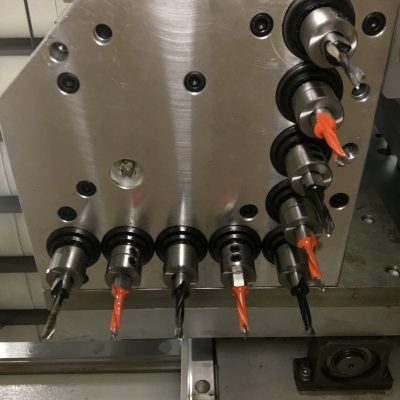

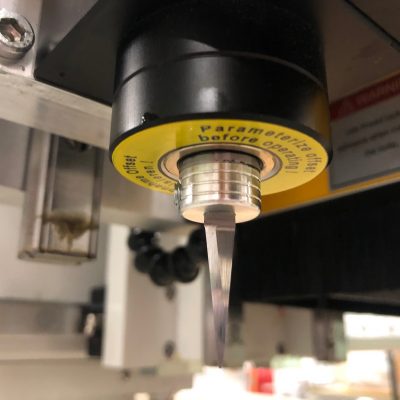

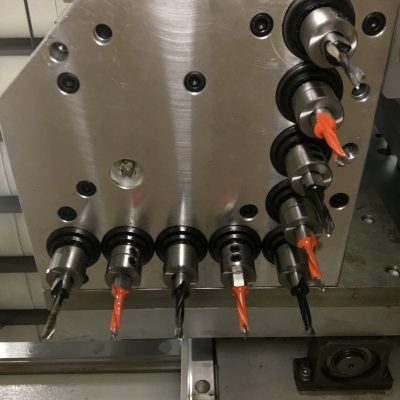

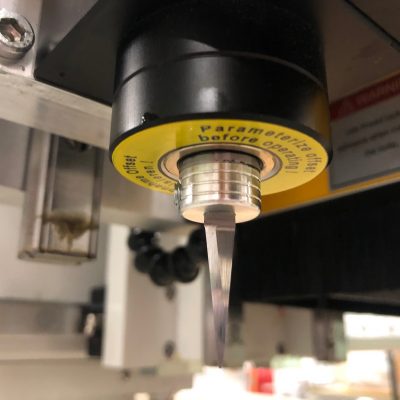

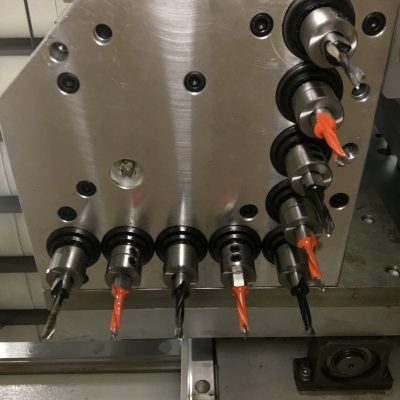

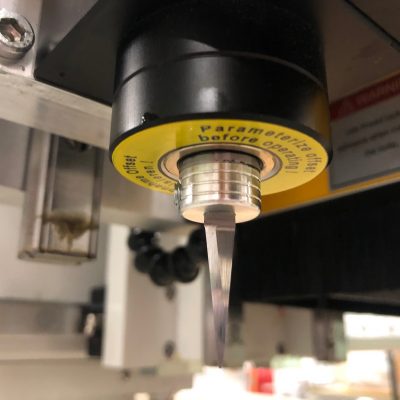

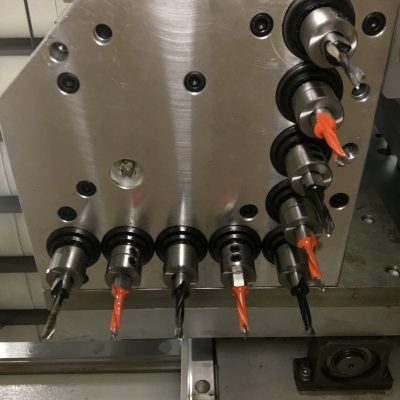

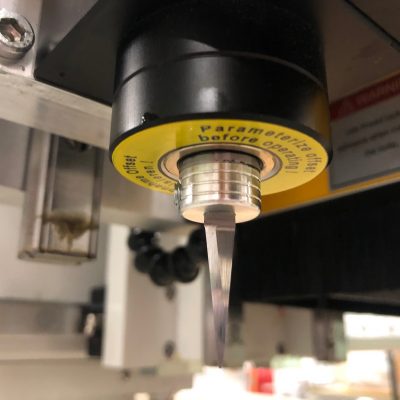

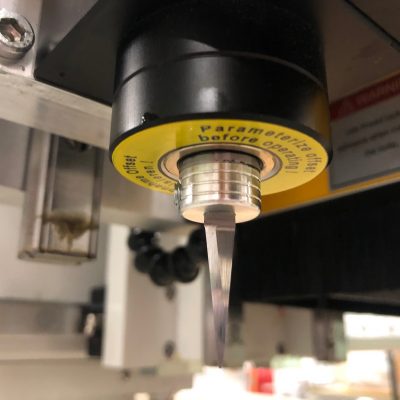

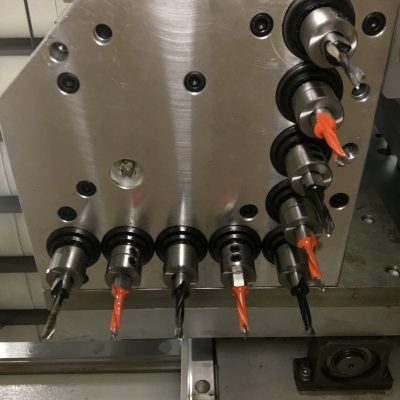

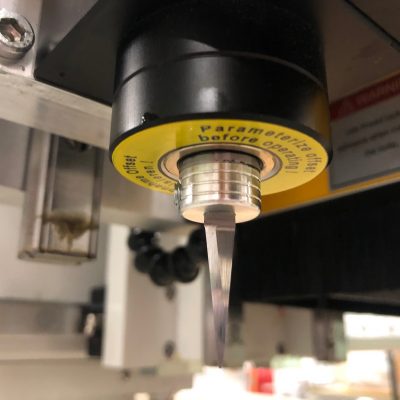

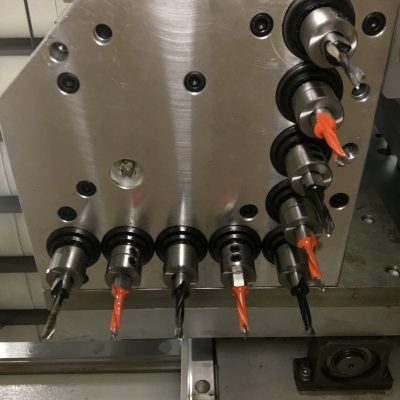

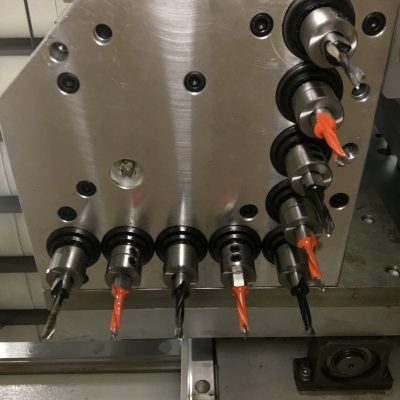

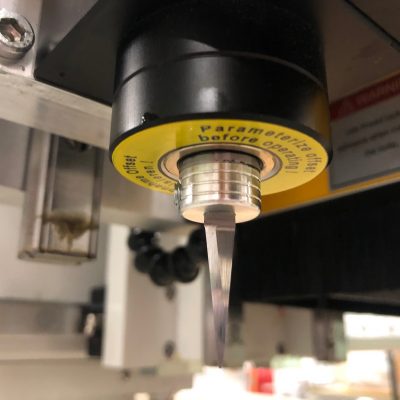

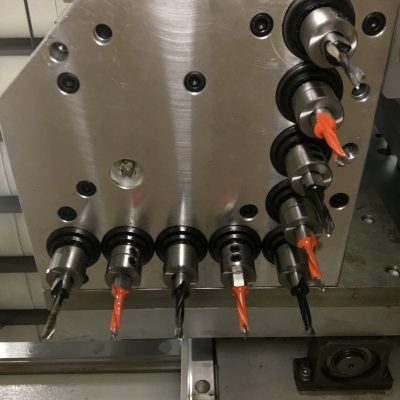

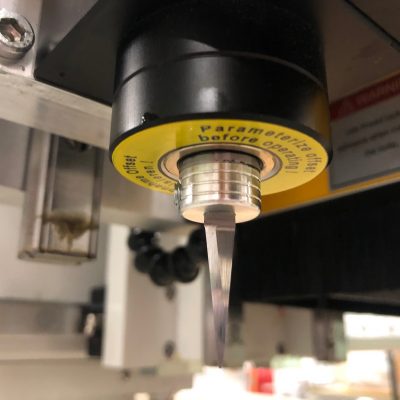

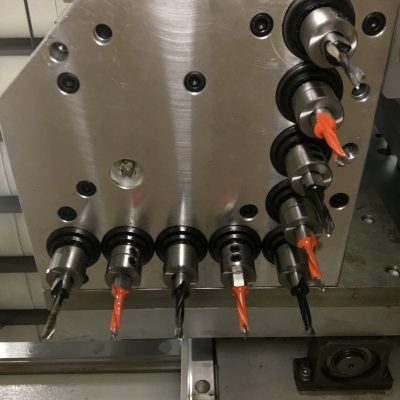

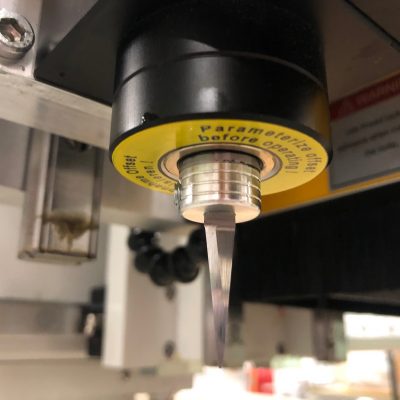

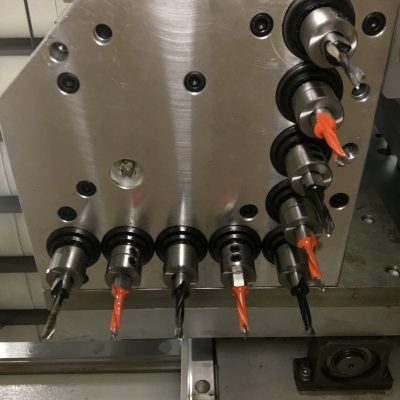

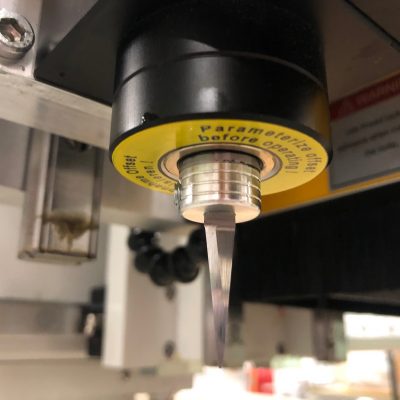

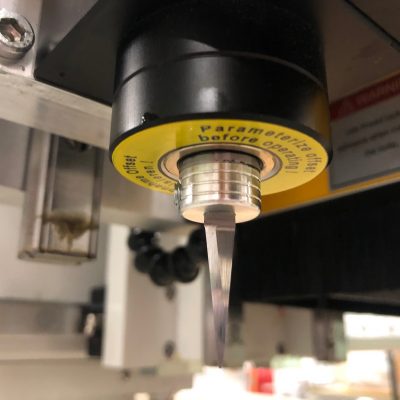

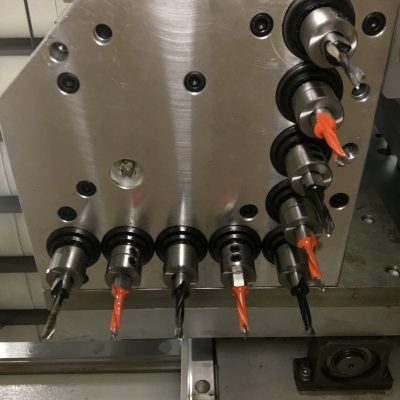

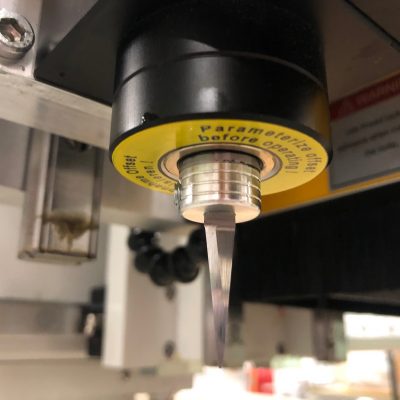

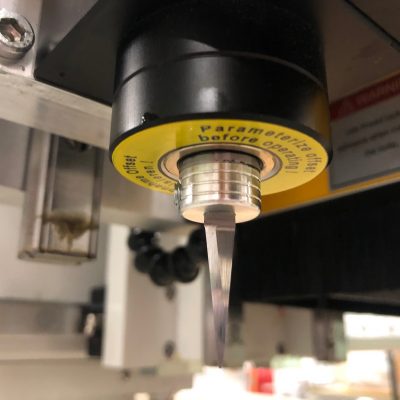

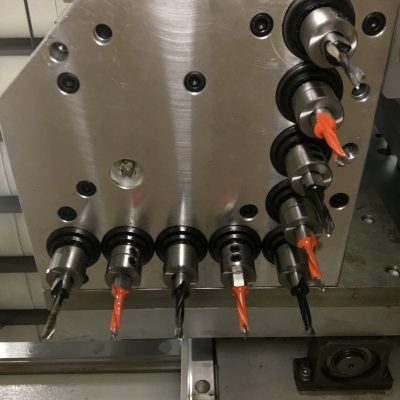

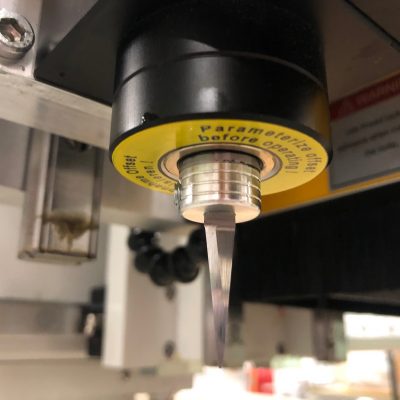

Spindle

The HDS Series machine comes standard with a 12 HP HSD high frequency automatic tool changer spindle. This precision spindle requires no maintenance, uses industry standard ER collets and ISO 30 tool holders, is fully programmable with speeds from 6000 to 24000 RPM, and comes complete with a pneumatically retractable vacuum hood.

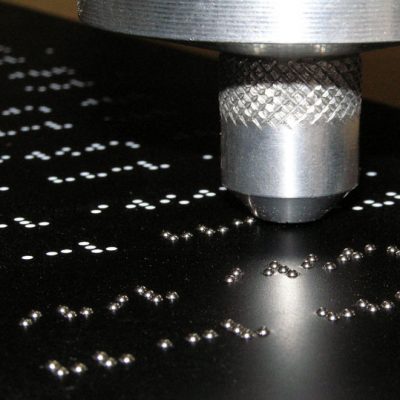

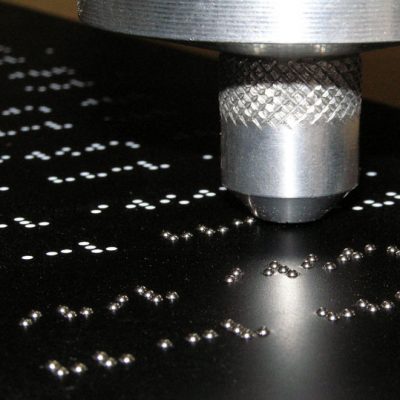

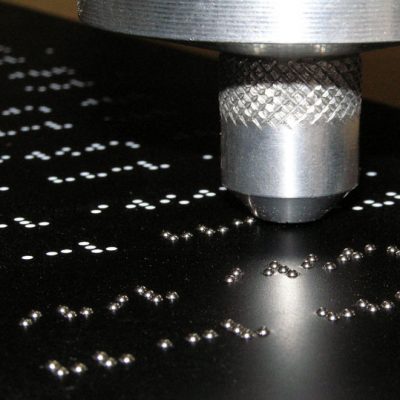

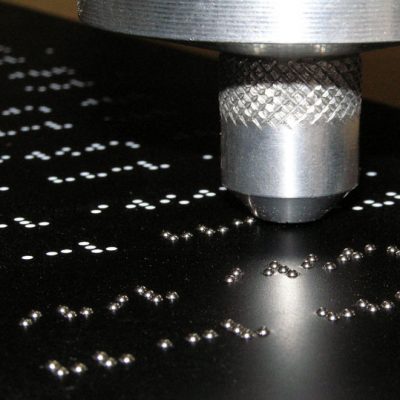

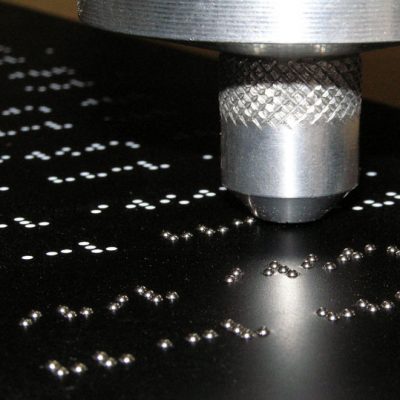

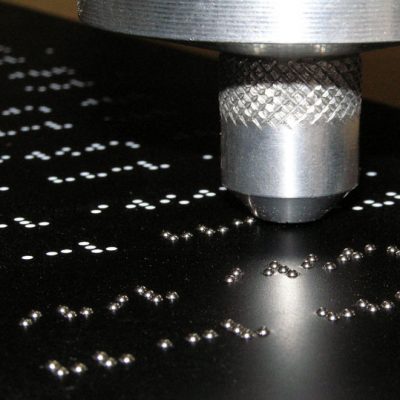

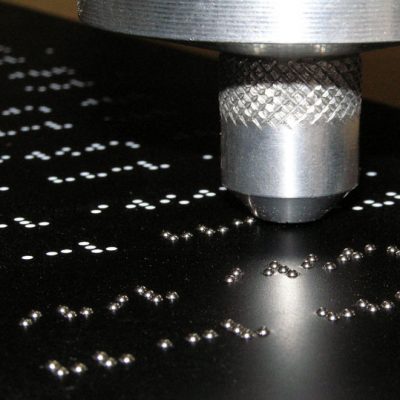

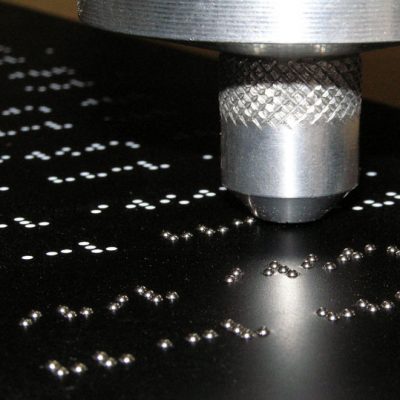

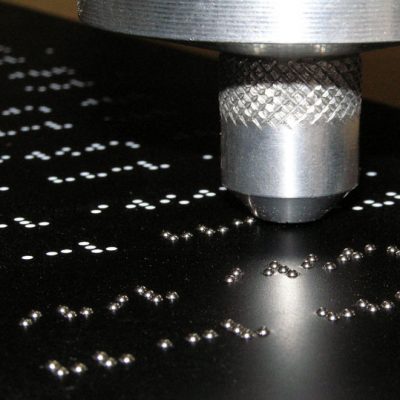

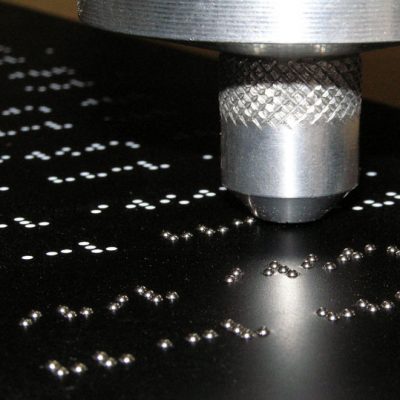

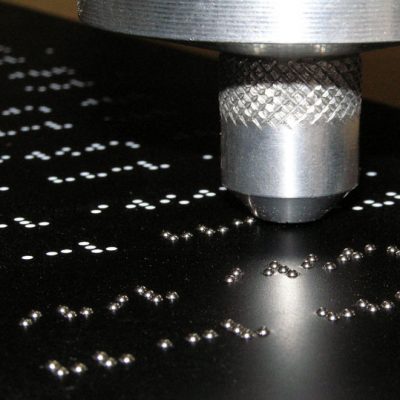

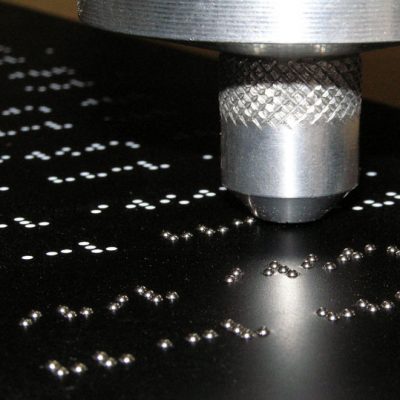

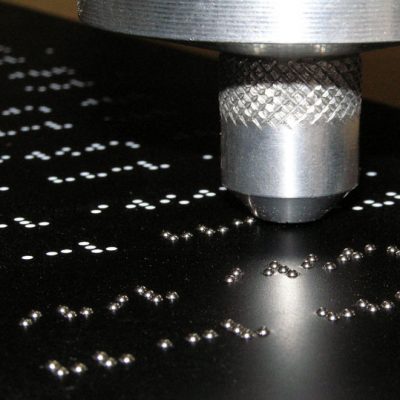

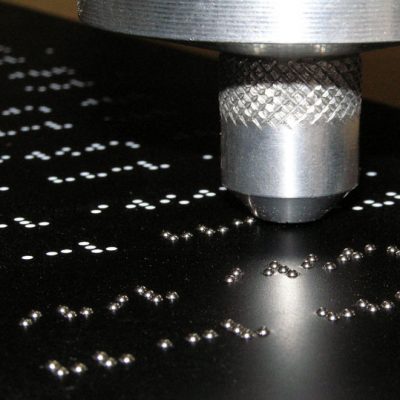

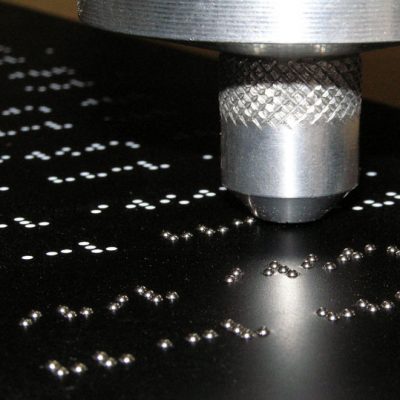

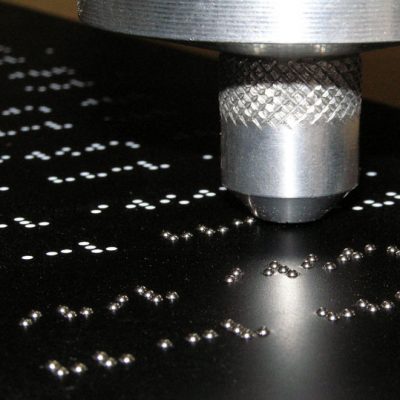

Vacuum Table

The vacuum plenum table surface is multi-zoned which allows the operator to easily switch from full sheet processing to smaller part processing (which requires a smaller segmented area). Zones can be turned off easily via control valves on the front of the machine. Gasketing can also be routed to accommodate various material sizes and styles.

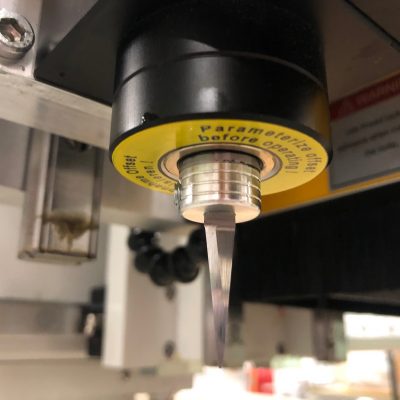

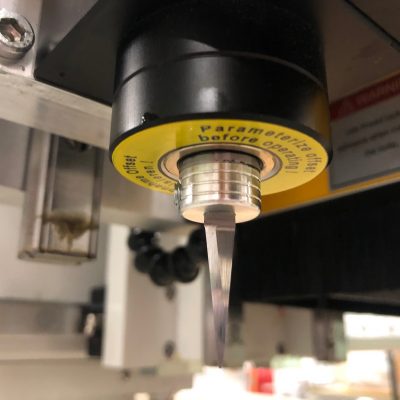

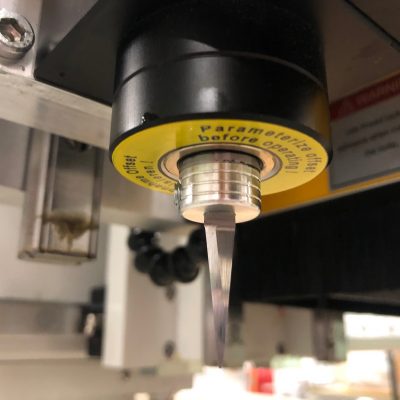

Vacuum Shroud

The HDS includes a pneumatically operated vacuum hood that has concentrated air flow at the spindle thus efficiently cleaning up the dust and debris as it is routed.

Read More

Drive Train Assembly

The Techno HDS Series CNC Router uses precision helical gear racks on the X and Y axes. The mounting of the rack is inverted to help keep dust and debris from building up on the drive system, ensuring smooth motion and long term reliability. The precision gearbox is directly coupled to the Servo motor and pinion. This eliminates belt stretch inaccuracies assuring high-speed machining while the system positions the spindle accurately.

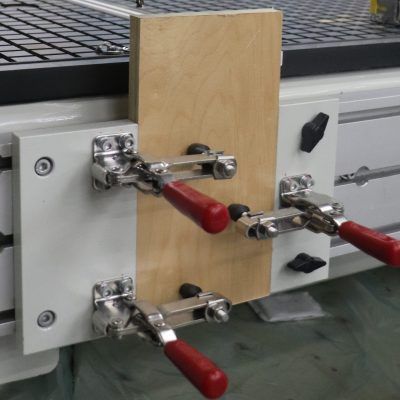

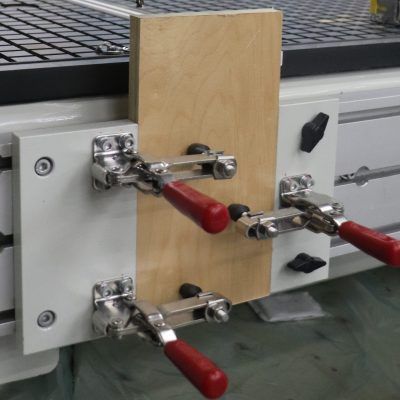

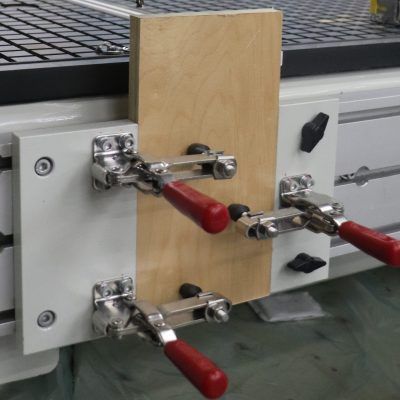

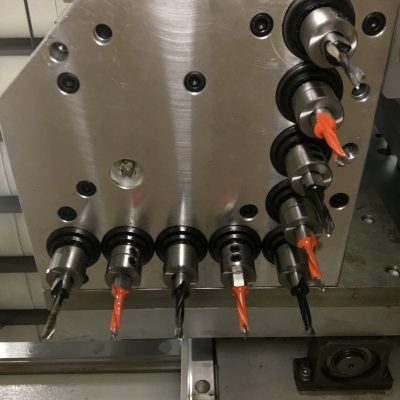

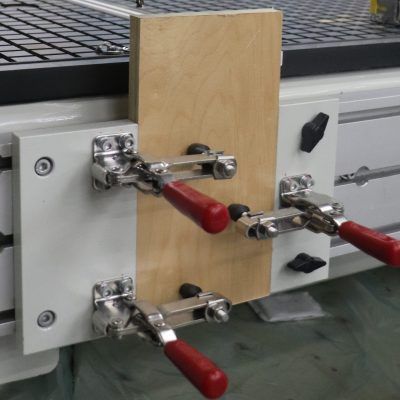

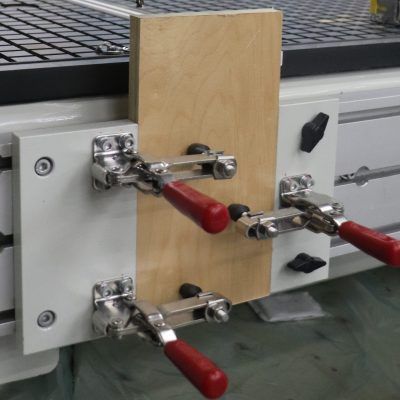

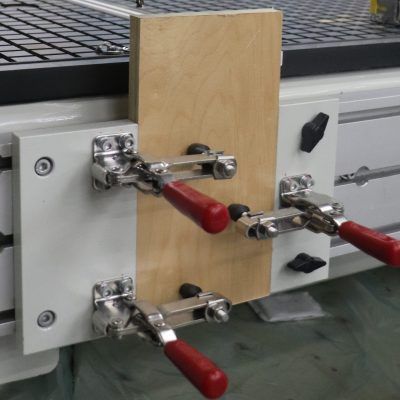

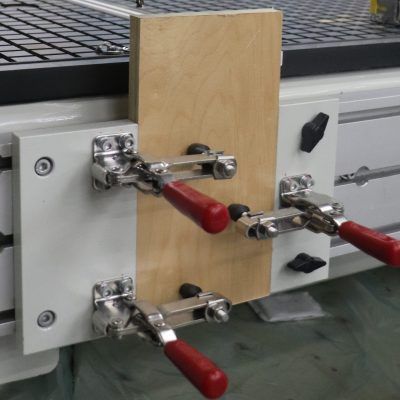

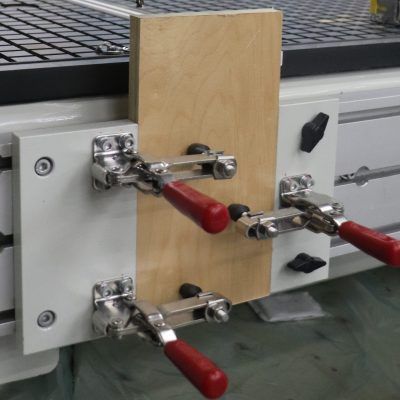

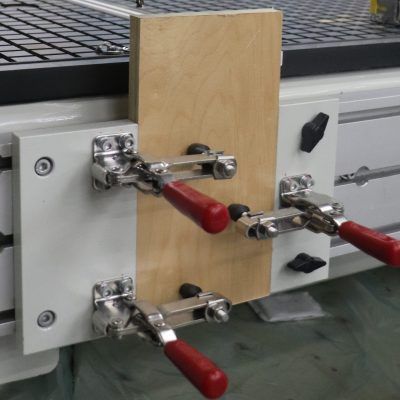

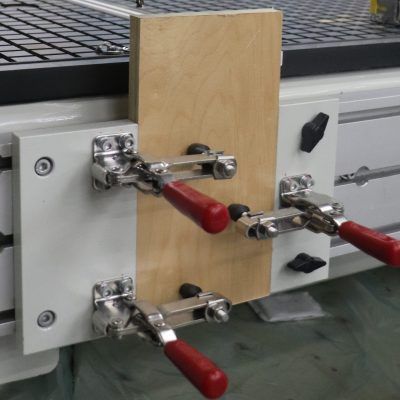

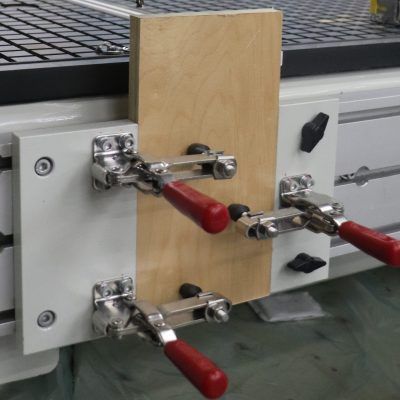

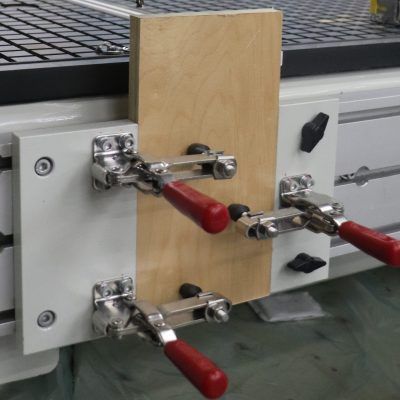

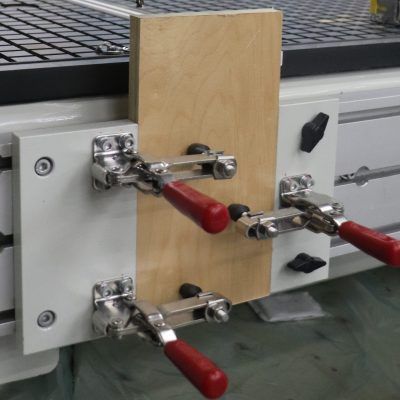

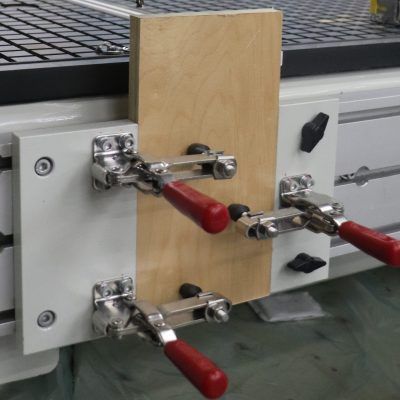

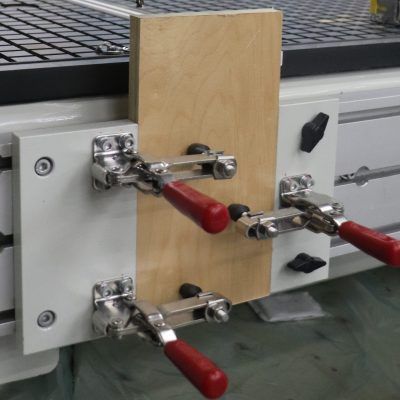

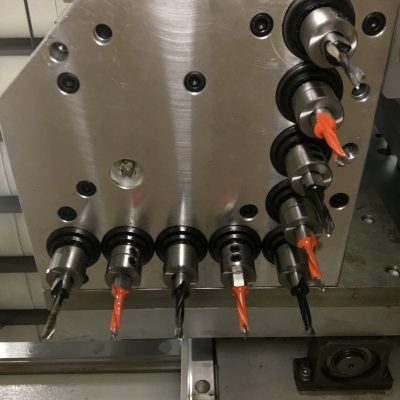

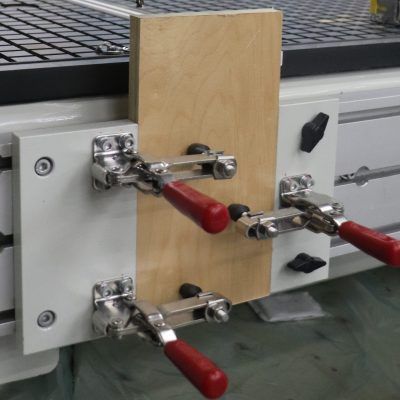

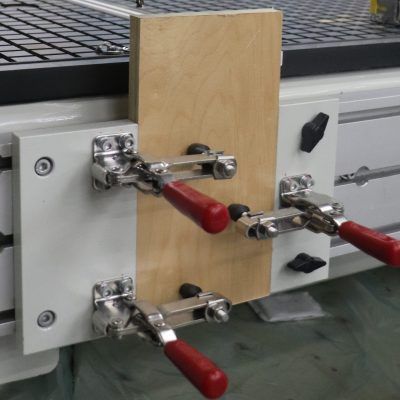

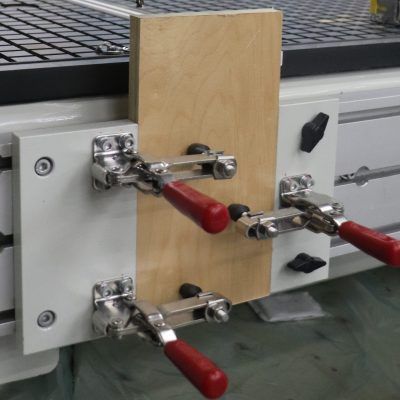

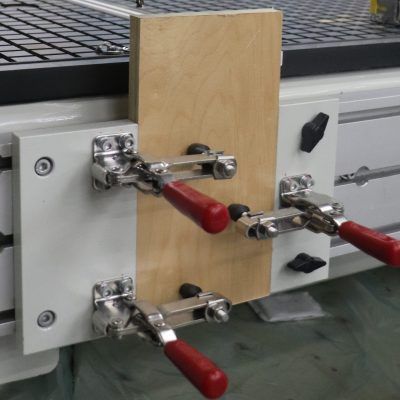

Tool Holder Clamp

The Techno HDS Series CNC Machine comes equipped with a tool holder clamp fixture, providing a much easier way of inserting and tightening the CNC router bits into your tool holder. This method is safer and easier.

Electronics

All the electrical components are housed and wired in a doubled-doored Nema 4 electrical enclosure. This allows for easy access and service when needed. All wiring is tagged so that when service is required, the customer can easily navigate the cabinet.

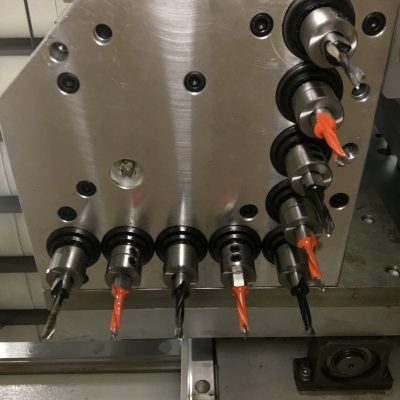

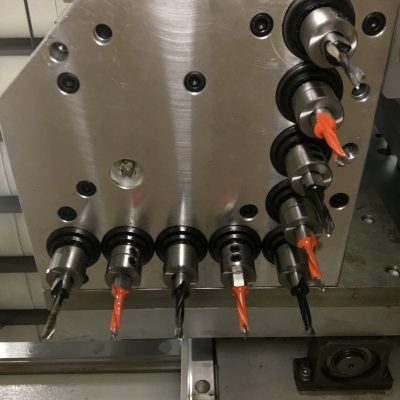

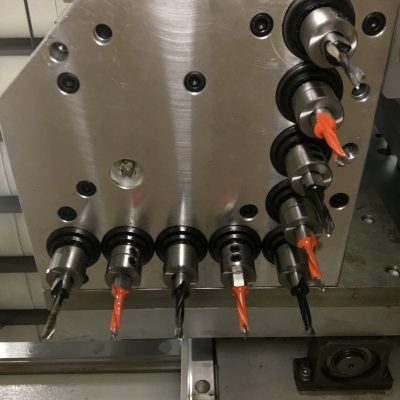

Tooling

The HDS Series machine includes an 8-position tool rack in the rear of the machine. The position of this rack allows for easy loading and unloading of material from either side of the machine.

Drive Motors

The HDS Series CNC Router utilizes AC Servo motors powered by Yaskowa drives. These motors require no regular maintenance — therefore, reducing any maintenance downtime.

Manual Pulse Generator

The MPG allows the operator to move around the machine, making for easy setup

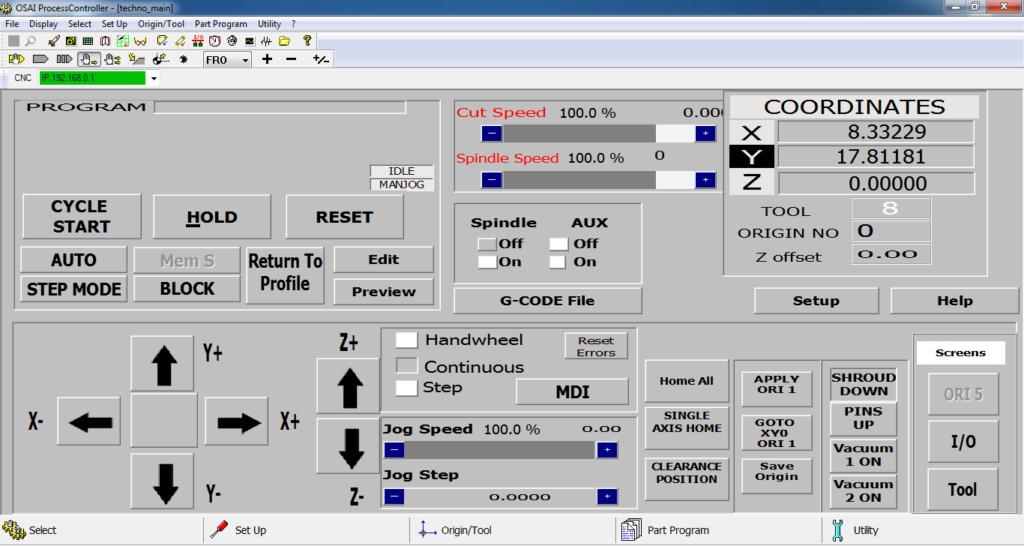

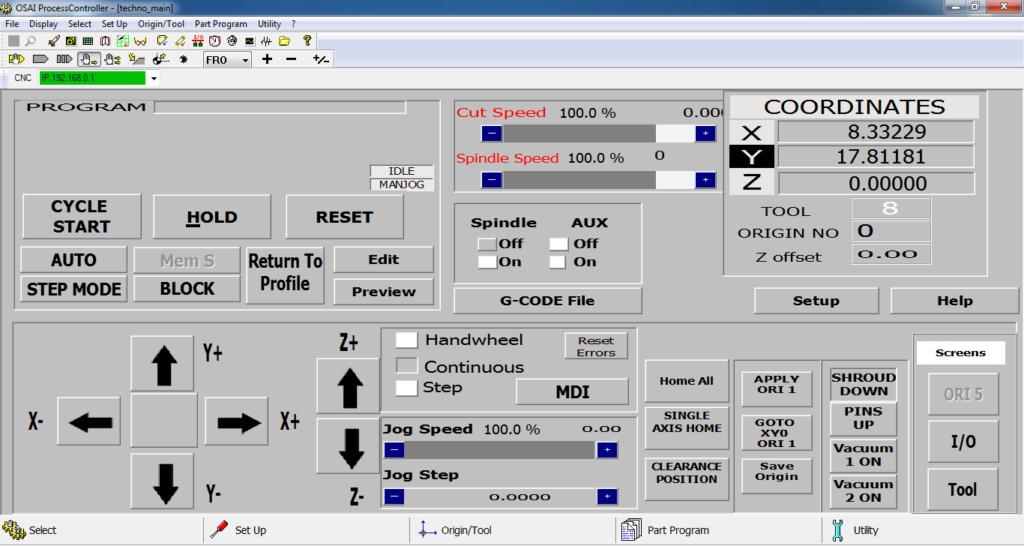

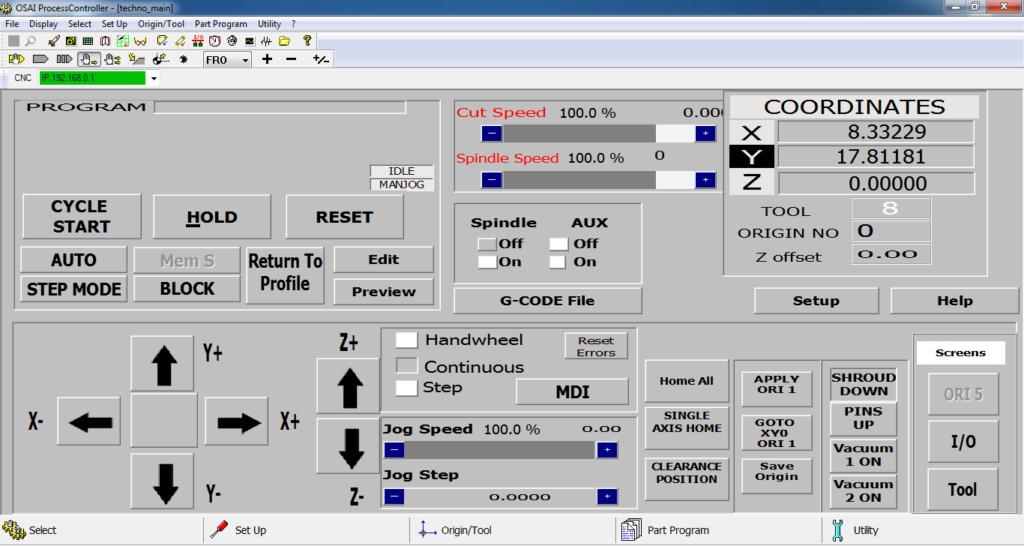

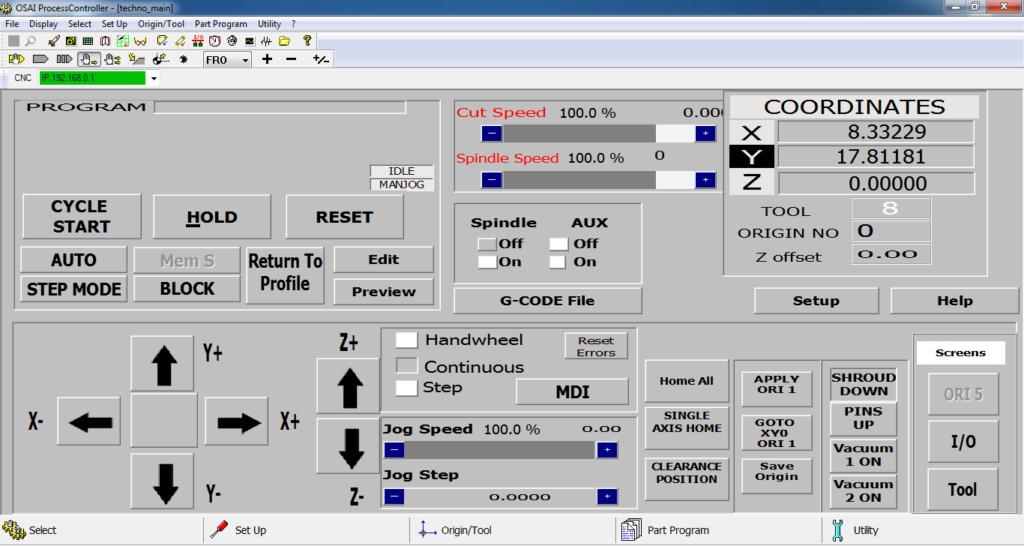

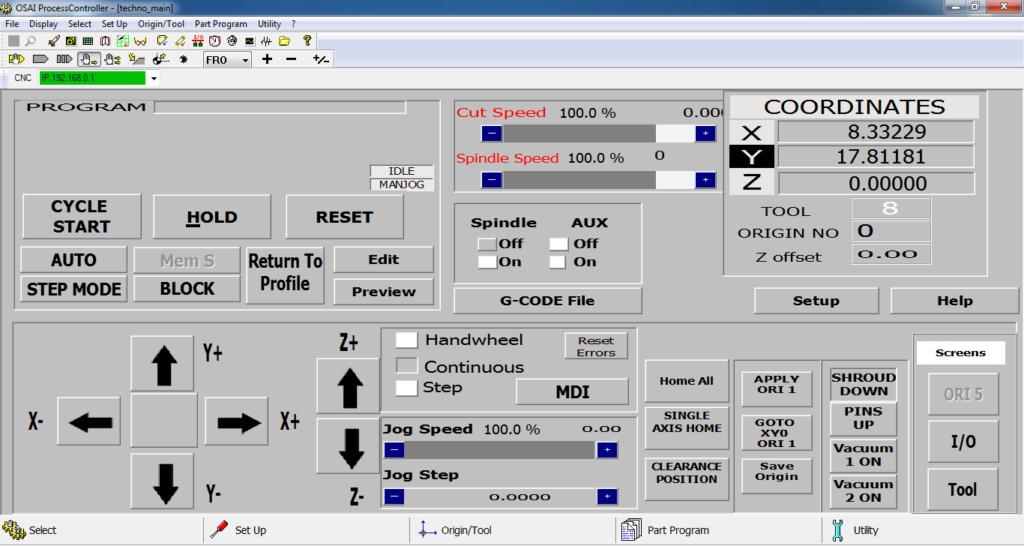

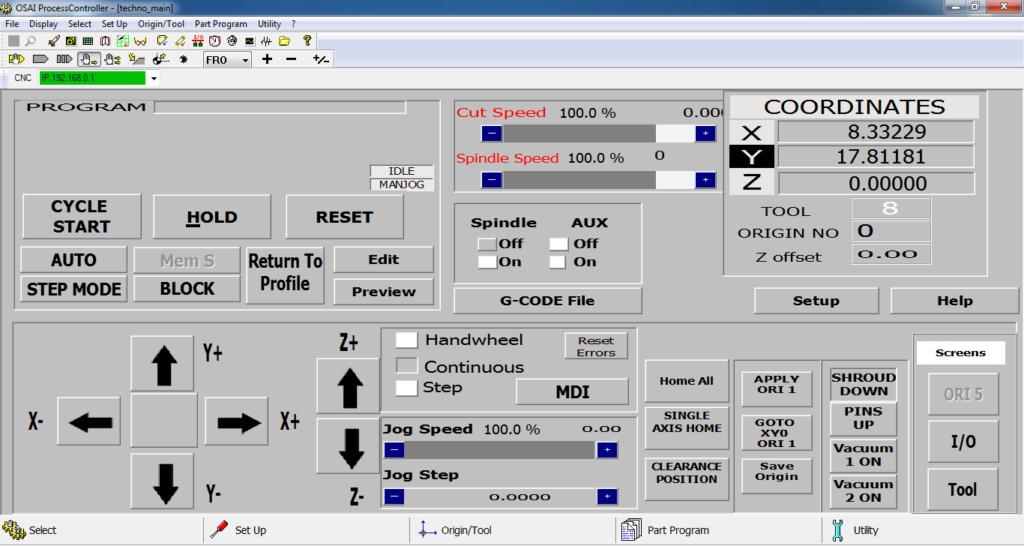

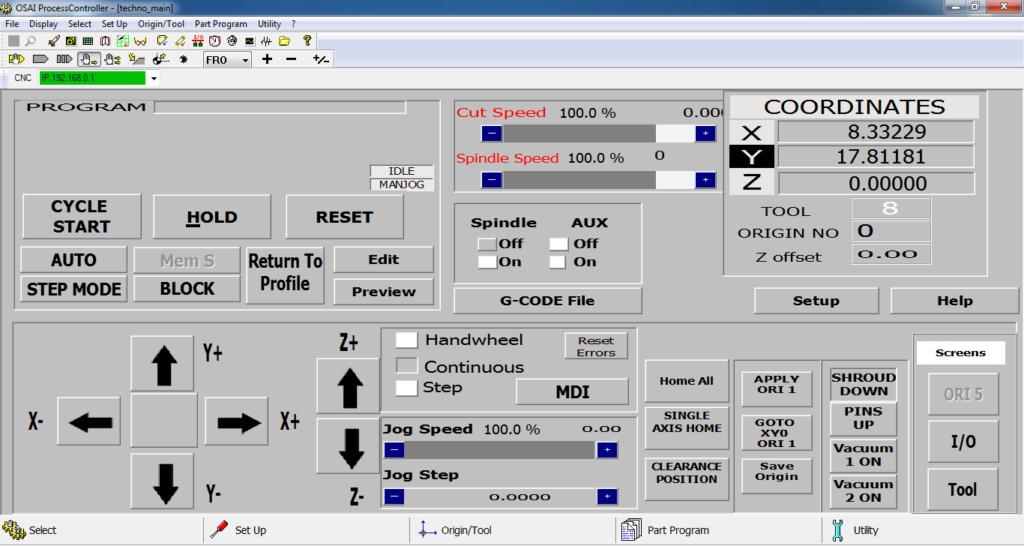

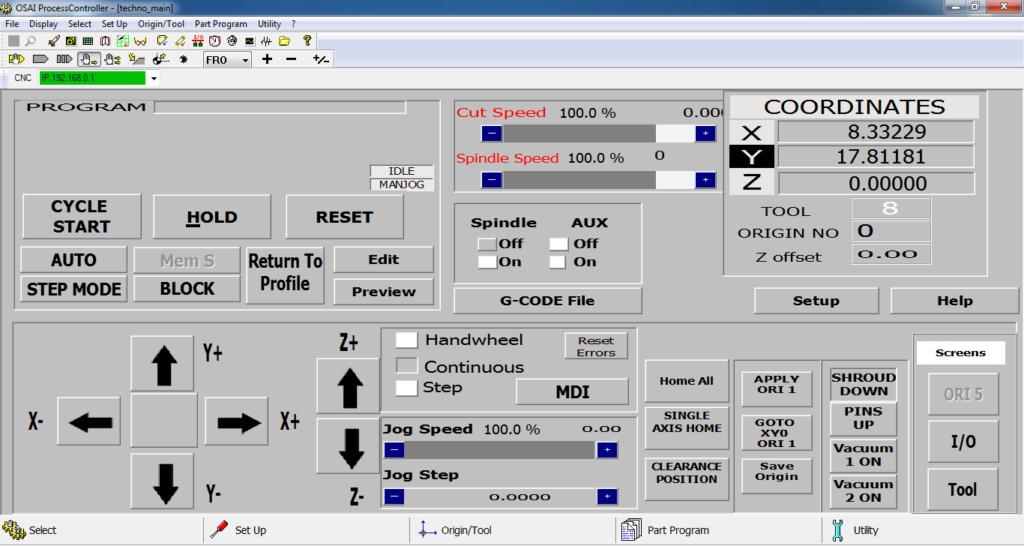

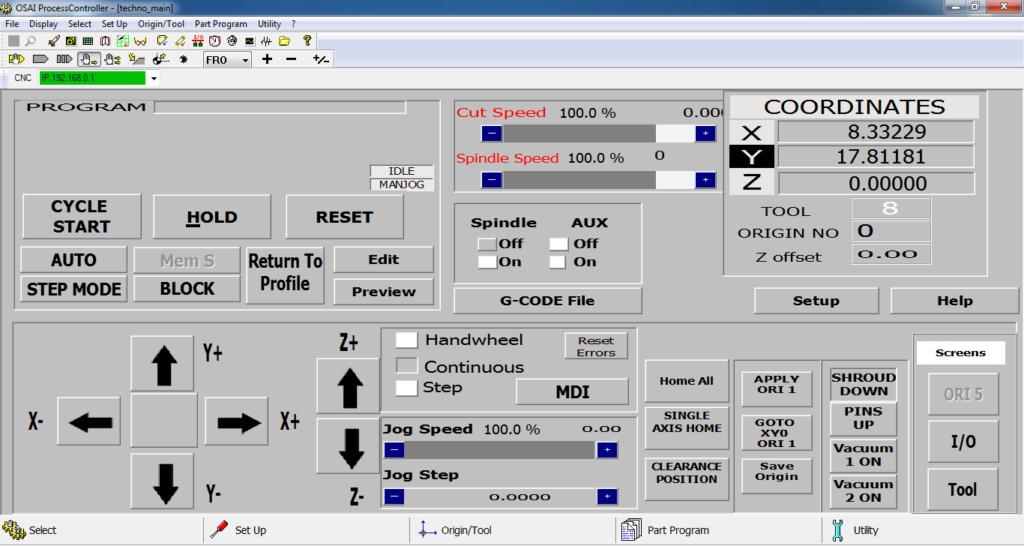

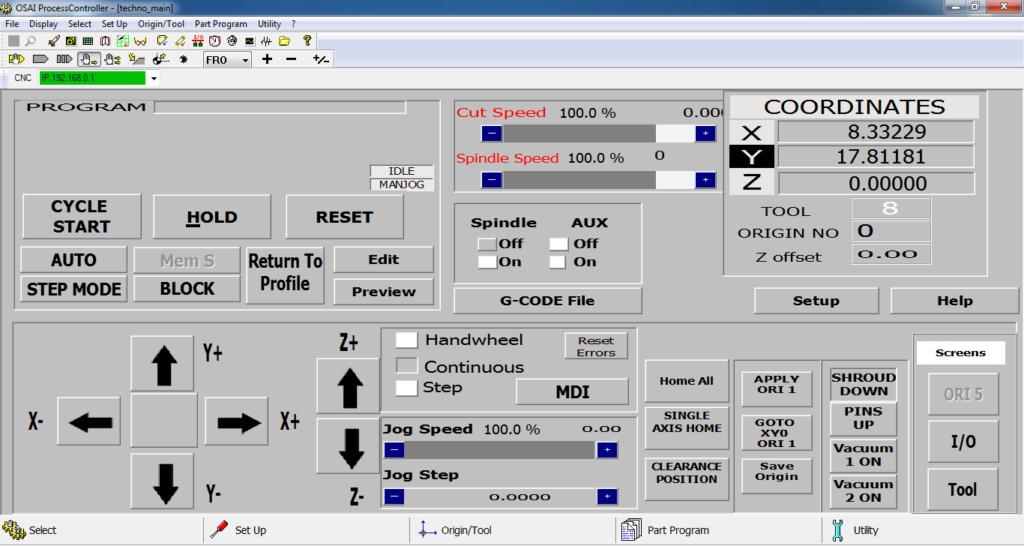

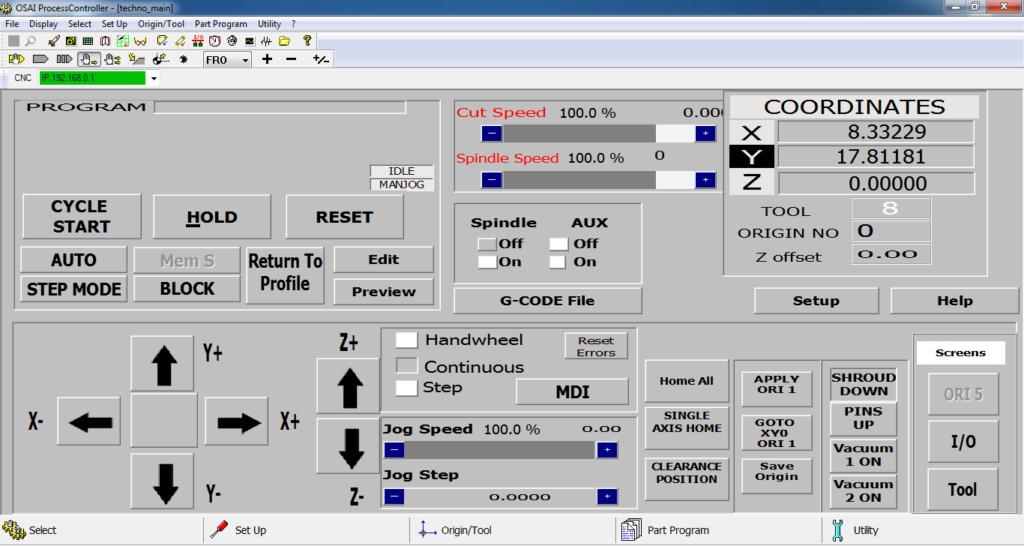

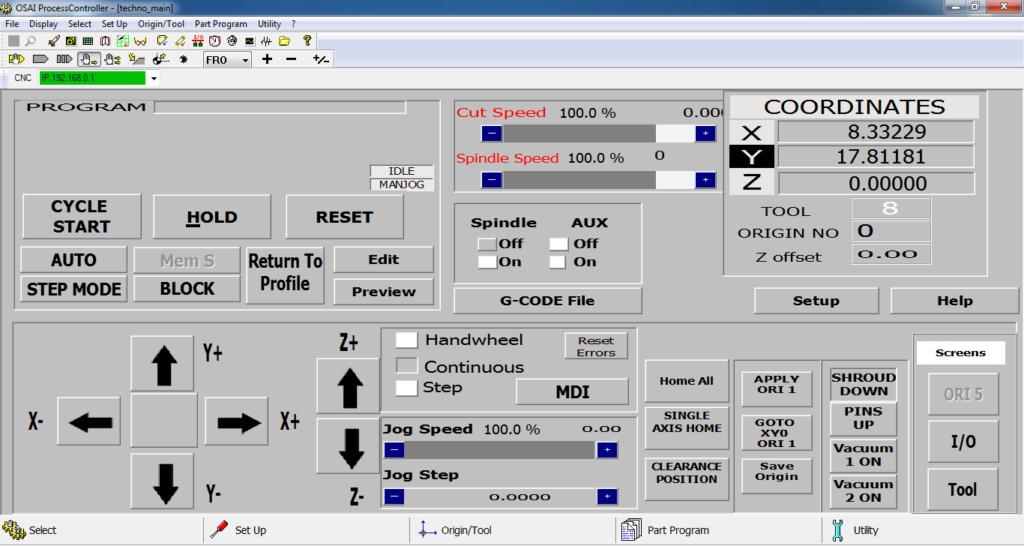

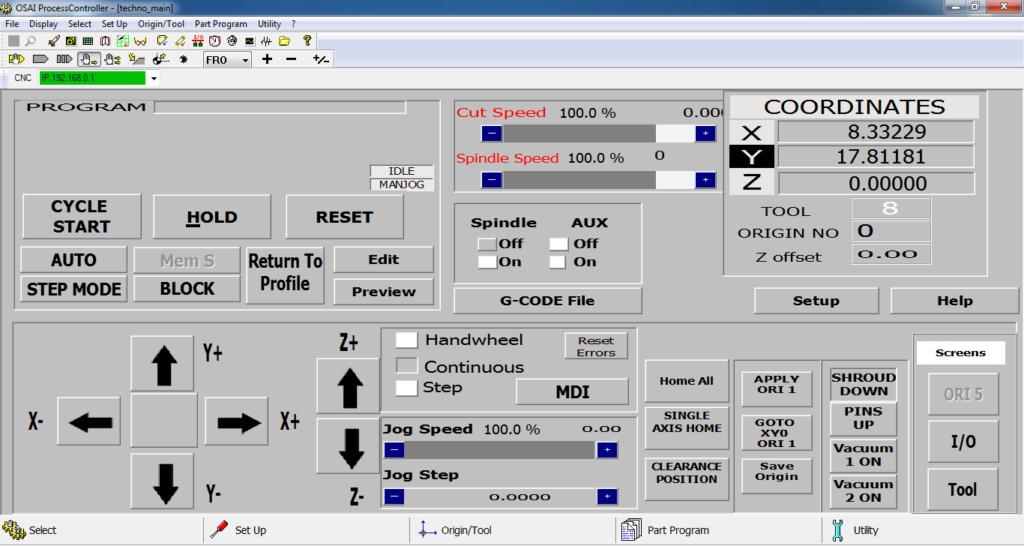

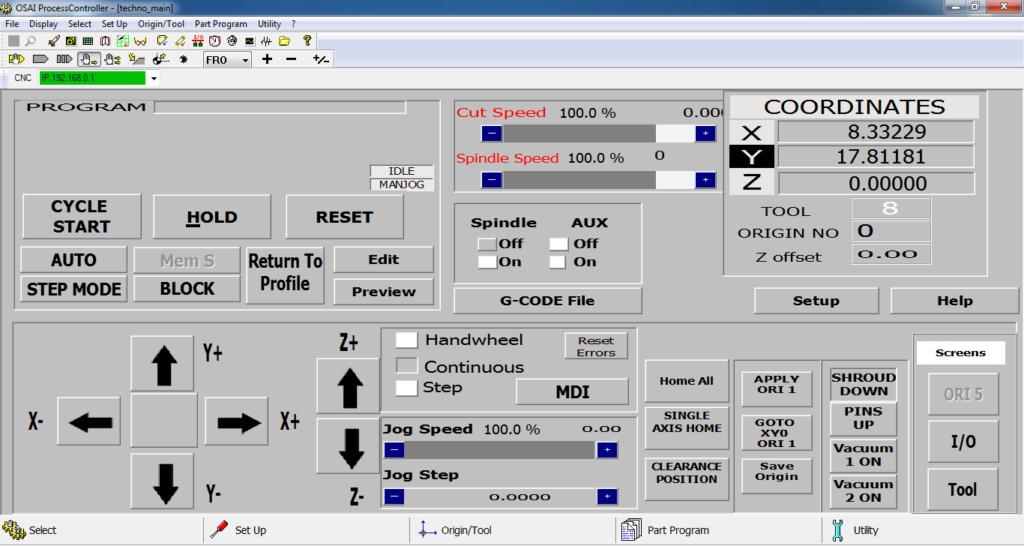

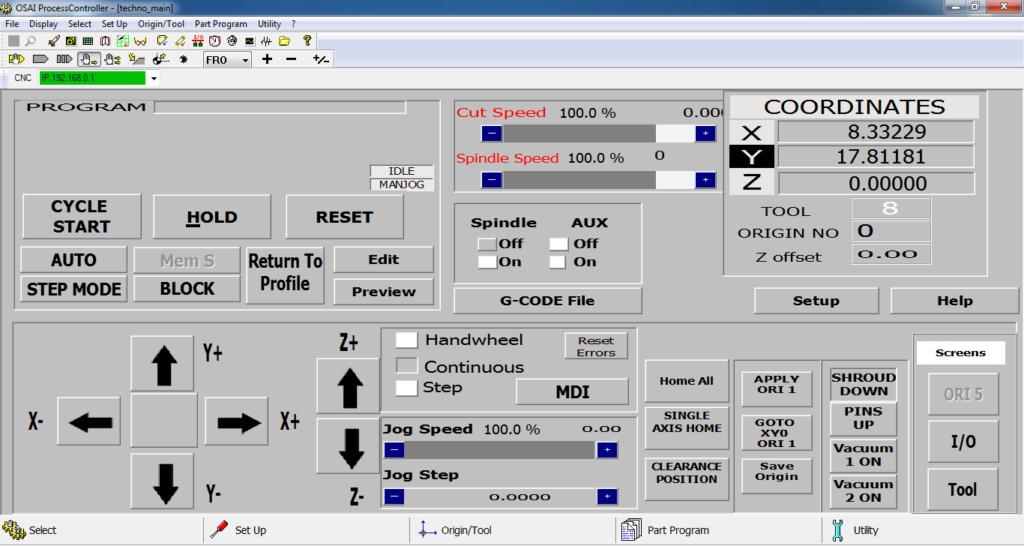

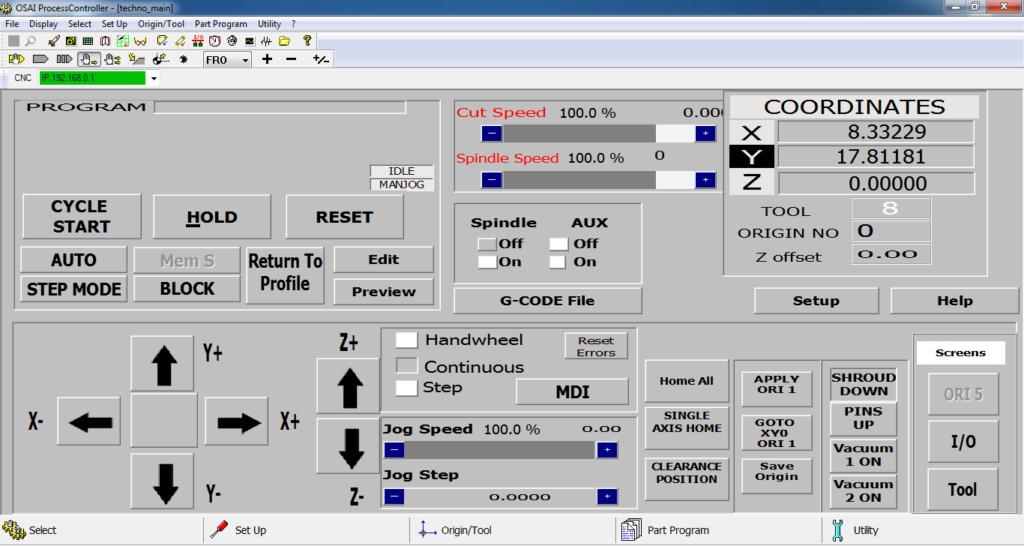

ABOUT THE OSAI CONTROLLER

The Venture Plus model machine is controlled via an Industrial Osai open series PC based CNC controller. OSAI is based on multi-platform software architecture. The real time multi-task operating system offers accurate and safe axis control that can be completed with the system’s own technological algorithms. Additionally, a standard Windows operating system provides a friendly and familiar operator interface. OSAI combines the ease-of-use, flexibility, and connectivity of a fully equipped Windows PC, with the power, durability, reliability, and serviceability of a true CNC machine controller.

Key features:

- Full automated tool length offset cycle

- Remote access

- Intuitive design and operation

- Skip functionality

- Backlash compensation

- Cutter compensation

- Full 3D capability with helical interpolation

- Highly Customizable

- Built-in editor for shop floor modifications

- Machine feed rate and spindle override control

- Continuous step jogging, or convenient hand-held pulse

- Generator can be used to fine tune positional locations

- CNC NC code previewer

- I/O machine status display

- Convenient vacuum pump switches on console interface

- Convenient pop-up pin switches on console interface

- Real time file execution

- Networkable

- System includes PC, monitor, keyboard, mouse, and work

- Platform on the control cabinet

Customer Reviews

MACHINE Options

Take a Closer Look at What This Machine Can Do

MACHINE VIDEO GALLERY

The HDS Series

Techno’s HDS Series CNC Machine is made up of all steel construction, providing the rigid foundation required for ultra-smooth routing results. The HDS Series CNC Router includes a 12 HP HSD automatic tool changer spindle with an 8-position tool rack, and comes standard with a pneumatically operated dust collection hood that concentrates air flow at the cutter, providing optimal dust collection performance. The multi-zone vacuum t-slot table is constructed from very hard Phenolic; an extremely stable material that holds tight tolerances for precision cutting. This CNC machine is connected to a 10HP rotary vane vacuum pump (twin pack optional), for quiet operation. For easy sheet alignment, (3) pop-up pins are included on the HDS Series, and are precisely placed to handle and align various size materials. The HDS Series CNC Machine is powered by brushless AC Servo digital motors and drives, and is powered by an easy-to-use and learn Osai PC based industrial controller.

Featured List

All steel construction

12 HP HSD high frequency automatic tool changer spindle

4-Zone vacuum t-slot table

Material pop-up pins for easy sheet alignment

Osai PC based Industrial grade CNC controller

Brushless digital AC servo motors and drives

Features

Steel Base

The HDS Series base frame is fabricated from heavy-duty tubular steel that is welded, precision machined and stress relieved so that the foundation remains true and steady over the operational life of the machine.

Gantry

The gantry is constructed of tubular steel with reinforcing ribs welded throughout the length of the column which results in a steady firm beam assembly. This quality engineering and workmanship result in smooth precision cutting.

Spindle

The HDS Series machine comes standard with a 12 HP HSD high frequency automatic tool changer spindle. This precision spindle requires no maintenance, uses industry standard ER collets and ISO 30 tool holders, is fully programmable with speeds from 6000 to 24000 RPM, and comes complete with a pneumatically retractable vacuum hood.

Vacuum Table

The vacuum plenum table surface is multi-zoned which allows the operator to easily switch from full sheet processing to smaller part processing (which requires a smaller segmented area). Zones can be turned off easily via control valves on the front of the machine. Gasketing can also be routed to accommodate various material sizes and styles.

Gantry Uprights

The gantry uprights are cast iron with heavy duty gussets formed into the casting. Each support is machined for housing the various drive assemblies including motors, bearings, and wiring harnesses.

Vacuum Shroud

The HDS includes a pneumatically operated vacuum hood that has concentrated air flow at the spindle thus efficiently cleaning up the dust and debris as it is routed.

Read More

Drive Train Assembly

The Techno HDS Series CNC Router uses precision helical gear racks on the X and Y axes. The mounting of the rack is inverted to help keep dust and debris from building up on the drive system, ensuring smooth motion and long term reliability. The precision gearbox is directly coupled to the Servo motor and pinion. This eliminates belt stretch inaccuracies assuring high-speed machining while the system positions the spindle accurately.

Tool Holder Clamp

The Techno HDS Series CNC Machine comes equipped with a tool holder clamp fixture, providing a much easier way of inserting and tightening the CNC router bits into your tool holder. This method is safer and easier.

Electronics

All the electrical components are housed and wired in a doubled-doored Nema 4 electrical enclosure. This allows for easy access and service when needed. All wiring is tagged so that when service is required, the customer can easily navigate the cabinet.

Tooling

The HDS Series machine includes an 8-position tool rack in the rear of the machine. The position of this rack allows for easy loading and unloading of material from either side of the machine.

Drive Motors

The HDS Series CNC Router utilizes AC Servo motors powered by Yaskowa drives. These motors require no regular maintenance — therefore, reducing any maintenance downtime.

Manual Pulse Generator

The MPG allows the operator to move around the machine, making for easy setup

ABOUT THE OSAI CONTROLLER

The Venture Plus model machine is controlled via an Industrial Osai open series PC based CNC controller. OSAI is based on multi-platform software architecture. The real time multi-task operating system offers accurate and safe axis control that can be completed with the system's own technological algorithms. Additionally, a standard Windows operating system provides a friendly and familiar operator interface. OSAI combines the ease-of-use, flexibility, and connectivity of a fully equipped Windows PC, with the power, durability, reliability, and serviceability of a true CNC machine controller.

Key features:

- Full automated tool length offset cycle

- Remote access

- Intuitive design and operation

- Skip functionality

- Backlash compensation

- Cutter compensation

- Full 3D capability with helical interpolation

- Highly Customizable

- Built-in editor for shop floor modifications

- Machine feed rate and spindle override control

- Continuous step jogging, or convenient hand-held pulse

- Generator can be used to fine tune positional locations

- CNC NC code previewer

- I/O machine status display

- Convenient vacuum pump switches on console interface

- Convenient pop-up pin switches on console interface

- Real time file execution

- Networkable

- System includes PC, monitor, keyboard, mouse, and work

- Platform on the control cabinet

Customer Reviews

I made our CNC upgrade close to 10 years ago. We came back to Techno to upgrade. Now, my 5×10 HDS Series and desktop machines are growing old with me… working hard and having fun. Our machines never disappoint. The people are Techno are hard working, dependable, and precise, just like their machines. Thank you for playing such a huge part in my continued success and growth" Christian MagroACM Solutions “We are extremely satisfied with both of our Techno CNC machines. Our new Titan Series has been a huge upgrade from our older Techno model. This new CNC machine has made our production a lot easier. The tool changer has been a game changer. I am finding myself performing tasks that I would normally complete by hand. Anyone considering getting a CNC, look no further than Techno. Buy your last CNC first" Tom DaliaGalloup Guitars "Purchasing the Techno CNC HDS 5×10 router is one of the best decisions we have made. Being in a business where versatility is essential in our equipment. There are days we start with cutting standard plywoods, shift to cutting 3” thick foam, then finish the day cutting Sintra and acrylic... all with immense ease. The best part of having our router is having a great team stand behind their product. Any questions we have get answered very quick. The Techno team is top-notch and their dedication rivals that of other machine companies. We are extremely happy and have no regrets. The machine has allowed us to compete with companies 10-100x our size" Timothy DavidBreakthrough Productions “Overall, I am extremely satisfied with all three of my Techno CNC routers. My second CNC purchase from Techno CNC was even easier to learn how to use, since it had the same controller as my Premium class Series. And now that I purchased Techno's new Titan Series CNC router a few months ago and learned about Win CNC controllers, I can do so much more” Jared MenkeJared's Gunstocks "I am impressed with Techno’s technical support and fast response, confirming our pre-sales research and concerns in picking the right company. You are a phone call away. We wanted to give our students a leg up on competition in other schools. We wanted to go with the best of the best. Adding the tool changer and vacuum table is a big deal. Another perk of our CNC is how we are never restricted by a project size" Jessie PerisonRandolph High School "We have lasers & 3D printers but the CNC routers offer so much more. Techno CNC machines allow us the ability to use a variety of different materials, sizes and thicknesses. Another benefit of CNC machinery is having not just one, but two. We have double the capabilities for students to work hands-on with the routers - allowing for more one on one time with the routers & a smoother workshop class. We are extremely pleased with how our routers run" Leah AegerterAnderson Ranch Art Studio "We had a small issue with our 10’ Techno CNC this morning and when your tech called, he was very helpful and professional. I just thought you should know your team is very good. Thank you and tell your team we are very appreciative" Spencer TerpeningSRC Refrigeration “My Techno CNC router has been an excellent machine to enter into the CNC world. When purchasing a CNC router, I found Techno to be extremely reliable. Whenever I called Techno for a simple tech support question, a living breathing person answered the phone, and I know I am always going to get the answer immediately. I never feel as though I am getting pushed around. That was huge for my purchasing decision" Rob StaropoliRobert Staropoli Cabinetry "I wanted to thank you for your tech support for my Techno CNC Venture. Almost every company who sells you a machine and promises service will not give you the time of day. I cannot express my gratitude on the help I have received from Techno over the past 8 years. You and the team at Techno CNC stand behind what you sell. Once again, I would like to thank you for your service and reliable machinery" Scott HoeferInsight Exhibits "I’ve been meaning to drop you guys a note letting you know how much we appreciate the quality of the CNC machine, and the service we receive from Techno CNC. Having had a year and a half of time with the machine, we truly value it’s dependability, and virtually trouble free operation. That, combined with the speedy, friendly and knowledgeable service, are things we do not take for granted. Thank you for providing a high quality product, and great service" Bill StumpNew York Tent “I love your machines. They are work horse machines! We recently used the vacuum table to laminate plywood with thick veneer using a 3mill plastic sheet. It’s amazing that we are still finding many more uses for this machine other than its main purpose. It has opened so many possibilities and has given us more independence; allowing us to do things we used to sub out. I love being able to keep things in house as it allows us to have more control over our quality of work” Neil O'Moore-KlopfReither Woodworking “Our curriculum has switched from an Industrial Maintenance format to Advanced Manufacturing. The centerpiece is our Techno CNC machine. Our Techno CNC delivers exactly what we want: quality, repeatability, and speed in the manufacturing process. Utilizing CNC technology allows us to bring real world manufacturing into our classroom and gives our students an edge as they prepare for future careers in the manufacturing industry” Keith HaleCaroline Career and Tech Center “We used to print these parts and have them sent to a local machine shop for finishing. Our new Techno Goliath Series now allows us to keep work in-house and requires no hand finishing; saving us a lot of time and money. We are extremely pleased the new Techno Goliath machine will help stream line our manufacturing process with increased efficiency, quality and accuracy” ManagersWitchita State University "Our 3-axis @technocnc CNC router is the beating heart of rootlab. Everything we build is meticulously designed by our design team. Once designed many of the components pass through the capable hands of our digital fabrication team before being handed off to the next department. From simple templates to complex 2.5D sculpting, we use the CNC to mill all types of sheet goods including plywood, MDF, hardwood, aluminum, foam, solid surface, and acrylic". Root LabRoot Lab Previous NextMACHINE Options

Take a Closer Look at What This Machine Can Do

Previous Next Previous NextMACHINE VIDEO GALLERY

Play Play Play Play Play Play Play Play Play Play Brochure Request a quoteThe HDS Series

Techno’s HDS Series CNC Machine is made up of all steel construction, providing the rigid foundation required for ultra-smooth routing results. The HDS Series CNC Router includes a 12 HP HSD automatic tool changer spindle with an 8-position tool rack, and comes standard with a pneumatically operated dust collection hood that concentrates air flow at the cutter, providing optimal dust collection performance. The multi-zone vacuum t-slot table is constructed from very hard Phenolic; an extremely stable material that holds tight tolerances for precision cutting. This CNC machine is connected to a 10HP rotary vane vacuum pump (twin pack optional), for quiet operation. For easy sheet alignment, (3) pop-up pins are included on the HDS Series, and are precisely placed to handle and align various size materials. The HDS Series CNC Machine is powered by brushless AC Servo digital motors and drives, and is powered by an easy-to-use and learn Osai PC based industrial controller.

Featured List

All steel construction

12 HP HSD high frequency automatic tool changer spindle

4-Zone vacuum t-slot table

Material pop-up pins for easy sheet alignment

Osai PC based Industrial grade CNC controller

Brushless digital AC servo motors and drives

Features

Steel Base

The HDS Series base frame is fabricated from heavy-duty tubular steel that is welded, precision machined and stress relieved so that the foundation remains true and steady over the operational life of the machine.

Gantry

The gantry is constructed of tubular steel with reinforcing ribs welded throughout the length of the column which results in a steady firm beam assembly. This quality engineering and workmanship result in smooth precision cutting.

Spindle

The HDS Series machine comes standard with a 12 HP HSD high frequency automatic tool changer spindle. This precision spindle requires no maintenance, uses industry standard ER collets and ISO 30 tool holders, is fully programmable with speeds from 6000 to 24000 RPM, and comes complete with a pneumatically retractable vacuum hood.

Vacuum Table

The vacuum plenum table surface is multi-zoned which allows the operator to easily switch from full sheet processing to smaller part processing (which requires a smaller segmented area). Zones can be turned off easily via control valves on the front of the machine. Gasketing can also be routed to accommodate various material sizes and styles.

Gantry Uprights

The gantry uprights are cast iron with heavy duty gussets formed into the casting. Each support is machined for housing the various drive assemblies including motors, bearings, and wiring harnesses.

Vacuum Shroud

The HDS includes a pneumatically operated vacuum hood that has concentrated air flow at the spindle thus efficiently cleaning up the dust and debris as it is routed.

Read More

Drive Train Assembly

The Techno HDS Series CNC Router uses precision helical gear racks on the X and Y axes. The mounting of the rack is inverted to help keep dust and debris from building up on the drive system, ensuring smooth motion and long term reliability. The precision gearbox is directly coupled to the Servo motor and pinion. This eliminates belt stretch inaccuracies assuring high-speed machining while the system positions the spindle accurately.

Tool Holder Clamp

The Techno HDS Series CNC Machine comes equipped with a tool holder clamp fixture, providing a much easier way of inserting and tightening the CNC router bits into your tool holder. This method is safer and easier.

Electronics

All the electrical components are housed and wired in a doubled-doored Nema 4 electrical enclosure. This allows for easy access and service when needed. All wiring is tagged so that when service is required, the customer can easily navigate the cabinet.

Tooling

The HDS Series machine includes an 8-position tool rack in the rear of the machine. The position of this rack allows for easy loading and unloading of material from either side of the machine.

Drive Motors

The HDS Series CNC Router utilizes AC Servo motors powered by Yaskowa drives. These motors require no regular maintenance — therefore, reducing any maintenance downtime.

Manual Pulse Generator

The MPG allows the operator to move around the machine, making for easy setup

ABOUT THE OSAI CONTROLLER

The Venture Plus model machine is controlled via an Industrial Osai open series PC based CNC controller. OSAI is based on multi-platform software architecture. The real time multi-task operating system offers accurate and safe axis control that can be completed with the system's own technological algorithms. Additionally, a standard Windows operating system provides a friendly and familiar operator interface. OSAI combines the ease-of-use, flexibility, and connectivity of a fully equipped Windows PC, with the power, durability, reliability, and serviceability of a true CNC machine controller.

Key features:

- Full automated tool length offset cycle

- Remote access

- Intuitive design and operation

- Skip functionality

- Backlash compensation

- Cutter compensation

- Full 3D capability with helical interpolation

- Highly Customizable

- Built-in editor for shop floor modifications

- Machine feed rate and spindle override control

- Continuous step jogging, or convenient hand-held pulse

- Generator can be used to fine tune positional locations

- CNC NC code previewer

- I/O machine status display

- Convenient vacuum pump switches on console interface

- Convenient pop-up pin switches on console interface

- Real time file execution

- Networkable

- System includes PC, monitor, keyboard, mouse, and work

- Platform on the control cabinet

Customer Reviews

I made our CNC upgrade close to 10 years ago. We came back to Techno to upgrade. Now, my 5×10 HDS Series and desktop machines are growing old with me… working hard and having fun. Our machines never disappoint. The people are Techno are hard working, dependable, and precise, just like their machines. Thank you for playing such a huge part in my continued success and growth" Christian MagroACM Solutions “We are extremely satisfied with both of our Techno CNC machines. Our new Titan Series has been a huge upgrade from our older Techno model. This new CNC machine has made our production a lot easier. The tool changer has been a game changer. I am finding myself performing tasks that I would normally complete by hand. Anyone considering getting a CNC, look no further than Techno. Buy your last CNC first" Tom DaliaGalloup Guitars "Purchasing the Techno CNC HDS 5×10 router is one of the best decisions we have made. Being in a business where versatility is essential in our equipment. There are days we start with cutting standard plywoods, shift to cutting 3” thick foam, then finish the day cutting Sintra and acrylic... all with immense ease. The best part of having our router is having a great team stand behind their product. Any questions we have get answered very quick. The Techno team is top-notch and their dedication rivals that of other machine companies. We are extremely happy and have no regrets. The machine has allowed us to compete with companies 10-100x our size" Timothy DavidBreakthrough Productions “Overall, I am extremely satisfied with all three of my Techno CNC routers. My second CNC purchase from Techno CNC was even easier to learn how to use, since it had the same controller as my Premium class Series. And now that I purchased Techno's new Titan Series CNC router a few months ago and learned about Win CNC controllers, I can do so much more” Jared MenkeJared's Gunstocks "I am impressed with Techno’s technical support and fast response, confirming our pre-sales research and concerns in picking the right company. You are a phone call away. We wanted to give our students a leg up on competition in other schools. We wanted to go with the best of the best. Adding the tool changer and vacuum table is a big deal. Another perk of our CNC is how we are never restricted by a project size" Jessie PerisonRandolph High School "We have lasers & 3D printers but the CNC routers offer so much more. Techno CNC machines allow us the ability to use a variety of different materials, sizes and thicknesses. Another benefit of CNC machinery is having not just one, but two. We have double the capabilities for students to work hands-on with the routers - allowing for more one on one time with the routers & a smoother workshop class. We are extremely pleased with how our routers run" Leah AegerterAnderson Ranch Art Studio "We had a small issue with our 10’ Techno CNC this morning and when your tech called, he was very helpful and professional. I just thought you should know your team is very good. Thank you and tell your team we are very appreciative" Spencer TerpeningSRC Refrigeration “My Techno CNC router has been an excellent machine to enter into the CNC world. When purchasing a CNC router, I found Techno to be extremely reliable. Whenever I called Techno for a simple tech support question, a living breathing person answered the phone, and I know I am always going to get the answer immediately. I never feel as though I am getting pushed around. That was huge for my purchasing decision" Rob StaropoliRobert Staropoli Cabinetry "I wanted to thank you for your tech support for my Techno CNC Venture. Almost every company who sells you a machine and promises service will not give you the time of day. I cannot express my gratitude on the help I have received from Techno over the past 8 years. You and the team at Techno CNC stand behind what you sell. Once again, I would like to thank you for your service and reliable machinery" Scott HoeferInsight Exhibits "I’ve been meaning to drop you guys a note letting you know how much we appreciate the quality of the CNC machine, and the service we receive from Techno CNC. Having had a year and a half of time with the machine, we truly value it’s dependability, and virtually trouble free operation. That, combined with the speedy, friendly and knowledgeable service, are things we do not take for granted. Thank you for providing a high quality product, and great service" Bill StumpNew York Tent “I love your machines. They are work horse machines! We recently used the vacuum table to laminate plywood with thick veneer using a 3mill plastic sheet. It’s amazing that we are still finding many more uses for this machine other than its main purpose. It has opened so many possibilities and has given us more independence; allowing us to do things we used to sub out. I love being able to keep things in house as it allows us to have more control over our quality of work” Neil O'Moore-KlopfReither Woodworking “Our curriculum has switched from an Industrial Maintenance format to Advanced Manufacturing. The centerpiece is our Techno CNC machine. Our Techno CNC delivers exactly what we want: quality, repeatability, and speed in the manufacturing process. Utilizing CNC technology allows us to bring real world manufacturing into our classroom and gives our students an edge as they prepare for future careers in the manufacturing industry” Keith HaleCaroline Career and Tech Center “We used to print these parts and have them sent to a local machine shop for finishing. Our new Techno Goliath Series now allows us to keep work in-house and requires no hand finishing; saving us a lot of time and money. We are extremely pleased the new Techno Goliath machine will help stream line our manufacturing process with increased efficiency, quality and accuracy” ManagersWitchita State University "Our 3-axis @technocnc CNC router is the beating heart of rootlab. Everything we build is meticulously designed by our design team. Once designed many of the components pass through the capable hands of our digital fabrication team before being handed off to the next department. From simple templates to complex 2.5D sculpting, we use the CNC to mill all types of sheet goods including plywood, MDF, hardwood, aluminum, foam, solid surface, and acrylic". Root LabRoot Lab Previous NextMACHINE Options

Take a Closer Look at What This Machine Can Do

Previous Next Previous NextMACHINE VIDEO GALLERY

Play Play Play Play Play Play Play Play Play Play Brochure Request a quoteThe HDS Series

Techno’s HDS Series CNC Machine is made up of all steel construction, providing the rigid foundation required for ultra-smooth routing results. The HDS Series CNC Router includes a 12 HP HSD automatic tool changer spindle with an 8-position tool rack, and comes standard with a pneumatically operated dust collection hood that concentrates air flow at the cutter, providing optimal dust collection performance. The multi-zone vacuum t-slot table is constructed from very hard Phenolic; an extremely stable material that holds tight tolerances for precision cutting. This CNC machine is connected to a 10HP rotary vane vacuum pump (twin pack optional), for quiet operation. For easy sheet alignment, (3) pop-up pins are included on the HDS Series, and are precisely placed to handle and align various size materials. The HDS Series CNC Machine is powered by brushless AC Servo digital motors and drives, and is powered by an easy-to-use and learn Osai PC based industrial controller.

Featured List

All steel construction

12 HP HSD high frequency automatic tool changer spindle

4-Zone vacuum t-slot table

Material pop-up pins for easy sheet alignment

Osai PC based Industrial grade CNC controller

Brushless digital AC servo motors and drives

Features

Steel Base

The HDS Series base frame is fabricated from heavy-duty tubular steel that is welded, precision machined and stress relieved so that the foundation remains true and steady over the operational life of the machine.

Gantry

The gantry is constructed of tubular steel with reinforcing ribs welded throughout the length of the column which results in a steady firm beam assembly. This quality engineering and workmanship result in smooth precision cutting.

Spindle

The HDS Series machine comes standard with a 12 HP HSD high frequency automatic tool changer spindle. This precision spindle requires no maintenance, uses industry standard ER collets and ISO 30 tool holders, is fully programmable with speeds from 6000 to 24000 RPM, and comes complete with a pneumatically retractable vacuum hood.

Vacuum Table

The vacuum plenum table surface is multi-zoned which allows the operator to easily switch from full sheet processing to smaller part processing (which requires a smaller segmented area). Zones can be turned off easily via control valves on the front of the machine. Gasketing can also be routed to accommodate various material sizes and styles.

Gantry Uprights

The gantry uprights are cast iron with heavy duty gussets formed into the casting. Each support is machined for housing the various drive assemblies including motors, bearings, and wiring harnesses.

Vacuum Shroud

The HDS includes a pneumatically operated vacuum hood that has concentrated air flow at the spindle thus efficiently cleaning up the dust and debris as it is routed.

Read More

Drive Train Assembly

The Techno HDS Series CNC Router uses precision helical gear racks on the X and Y axes. The mounting of the rack is inverted to help keep dust and debris from building up on the drive system, ensuring smooth motion and long term reliability. The precision gearbox is directly coupled to the Servo motor and pinion. This eliminates belt stretch inaccuracies assuring high-speed machining while the system positions the spindle accurately.

Tool Holder Clamp

The Techno HDS Series CNC Machine comes equipped with a tool holder clamp fixture, providing a much easier way of inserting and tightening the CNC router bits into your tool holder. This method is safer and easier.

Electronics

All the electrical components are housed and wired in a doubled-doored Nema 4 electrical enclosure. This allows for easy access and service when needed. All wiring is tagged so that when service is required, the customer can easily navigate the cabinet.

Tooling

The HDS Series machine includes an 8-position tool rack in the rear of the machine. The position of this rack allows for easy loading and unloading of material from either side of the machine.

Drive Motors

The HDS Series CNC Router utilizes AC Servo motors powered by Yaskowa drives. These motors require no regular maintenance — therefore, reducing any maintenance downtime.

Manual Pulse Generator

The MPG allows the operator to move around the machine, making for easy setup

ABOUT THE OSAI CONTROLLER

The Venture Plus model machine is controlled via an Industrial Osai open series PC based CNC controller. OSAI is based on multi-platform software architecture. The real time multi-task operating system offers accurate and safe axis control that can be completed with the system's own technological algorithms. Additionally, a standard Windows operating system provides a friendly and familiar operator interface. OSAI combines the ease-of-use, flexibility, and connectivity of a fully equipped Windows PC, with the power, durability, reliability, and serviceability of a true CNC machine controller.

Key features:

- Full automated tool length offset cycle

- Remote access

- Intuitive design and operation

- Skip functionality

- Backlash compensation

- Cutter compensation

- Full 3D capability with helical interpolation

- Highly Customizable

- Built-in editor for shop floor modifications

- Machine feed rate and spindle override control

- Continuous step jogging, or convenient hand-held pulse

- Generator can be used to fine tune positional locations

- CNC NC code previewer

- I/O machine status display

- Convenient vacuum pump switches on console interface

- Convenient pop-up pin switches on console interface

- Real time file execution

- Networkable

- System includes PC, monitor, keyboard, mouse, and work

- Platform on the control cabinet

Customer Reviews

I made our CNC upgrade close to 10 years ago. We came back to Techno to upgrade. Now, my 5×10 HDS Series and desktop machines are growing old with me… working hard and having fun. Our machines never disappoint. The people are Techno are hard working, dependable, and precise, just like their machines. Thank you for playing such a huge part in my continued success and growth" Christian MagroACM Solutions “We are extremely satisfied with both of our Techno CNC machines. Our new Titan Series has been a huge upgrade from our older Techno model. This new CNC machine has made our production a lot easier. The tool changer has been a game changer. I am finding myself performing tasks that I would normally complete by hand. Anyone considering getting a CNC, look no further than Techno. Buy your last CNC first" Tom DaliaGalloup Guitars "Purchasing the Techno CNC HDS 5×10 router is one of the best decisions we have made. Being in a business where versatility is essential in our equipment. There are days we start with cutting standard plywoods, shift to cutting 3” thick foam, then finish the day cutting Sintra and acrylic... all with immense ease. The best part of having our router is having a great team stand behind their product. Any questions we have get answered very quick. The Techno team is top-notch and their dedication rivals that of other machine companies. We are extremely happy and have no regrets. The machine has allowed us to compete with companies 10-100x our size" Timothy DavidBreakthrough Productions “Overall, I am extremely satisfied with all three of my Techno CNC routers. My second CNC purchase from Techno CNC was even easier to learn how to use, since it had the same controller as my Premium class Series. And now that I purchased Techno's new Titan Series CNC router a few months ago and learned about Win CNC controllers, I can do so much more” Jared MenkeJared's Gunstocks "I am impressed with Techno’s technical support and fast response, confirming our pre-sales research and concerns in picking the right company. You are a phone call away. We wanted to give our students a leg up on competition in other schools. We wanted to go with the best of the best. Adding the tool changer and vacuum table is a big deal. Another perk of our CNC is how we are never restricted by a project size" Jessie PerisonRandolph High School "We have lasers & 3D printers but the CNC routers offer so much more. Techno CNC machines allow us the ability to use a variety of different materials, sizes and thicknesses. Another benefit of CNC machinery is having not just one, but two. We have double the capabilities for students to work hands-on with the routers - allowing for more one on one time with the routers & a smoother workshop class. We are extremely pleased with how our routers run" Leah AegerterAnderson Ranch Art Studio "We had a small issue with our 10’ Techno CNC this morning and when your tech called, he was very helpful and professional. I just thought you should know your team is very good. Thank you and tell your team we are very appreciative" Spencer TerpeningSRC Refrigeration “My Techno CNC router has been an excellent machine to enter into the CNC world. When purchasing a CNC router, I found Techno to be extremely reliable. Whenever I called Techno for a simple tech support question, a living breathing person answered the phone, and I know I am always going to get the answer immediately. I never feel as though I am getting pushed around. That was huge for my purchasing decision" Rob StaropoliRobert Staropoli Cabinetry "I wanted to thank you for your tech support for my Techno CNC Venture. Almost every company who sells you a machine and promises service will not give you the time of day. I cannot express my gratitude on the help I have received from Techno over the past 8 years. You and the team at Techno CNC stand behind what you sell. Once again, I would like to thank you for your service and reliable machinery" Scott HoeferInsight Exhibits "I’ve been meaning to drop you guys a note letting you know how much we appreciate the quality of the CNC machine, and the service we receive from Techno CNC. Having had a year and a half of time with the machine, we truly value it’s dependability, and virtually trouble free operation. That, combined with the speedy, friendly and knowledgeable service, are things we do not take for granted. Thank you for providing a high quality product, and great service" Bill StumpNew York Tent “I love your machines. They are work horse machines! We recently used the vacuum table to laminate plywood with thick veneer using a 3mill plastic sheet. It’s amazing that we are still finding many more uses for this machine other than its main purpose. It has opened so many possibilities and has given us more independence; allowing us to do things we used to sub out. I love being able to keep things in house as it allows us to have more control over our quality of work” Neil O'Moore-KlopfReither Woodworking “Our curriculum has switched from an Industrial Maintenance format to Advanced Manufacturing. The centerpiece is our Techno CNC machine. Our Techno CNC delivers exactly what we want: quality, repeatability, and speed in the manufacturing process. Utilizing CNC technology allows us to bring real world manufacturing into our classroom and gives our students an edge as they prepare for future careers in the manufacturing industry” Keith HaleCaroline Career and Tech Center “We used to print these parts and have them sent to a local machine shop for finishing. Our new Techno Goliath Series now allows us to keep work in-house and requires no hand finishing; saving us a lot of time and money. We are extremely pleased the new Techno Goliath machine will help stream line our manufacturing process with increased efficiency, quality and accuracy” ManagersWitchita State University "Our 3-axis @technocnc CNC router is the beating heart of rootlab. Everything we build is meticulously designed by our design team. Once designed many of the components pass through the capable hands of our digital fabrication team before being handed off to the next department. From simple templates to complex 2.5D sculpting, we use the CNC to mill all types of sheet goods including plywood, MDF, hardwood, aluminum, foam, solid surface, and acrylic". Root LabRoot Lab Previous NextMACHINE Options

Take a Closer Look at What This Machine Can Do

Previous Next Previous NextMACHINE VIDEO GALLERY

Play Play Play Play Play Play Play Play Play Play Brochure Request a quoteThe HDS Series

Techno’s HDS Series CNC Machine is made up of all steel construction, providing the rigid foundation required for ultra-smooth routing results. The HDS Series CNC Router includes a 12 HP HSD automatic tool changer spindle with an 8-position tool rack, and comes standard with a pneumatically operated dust collection hood that concentrates air flow at the cutter, providing optimal dust collection performance. The multi-zone vacuum t-slot table is constructed from very hard Phenolic; an extremely stable material that holds tight tolerances for precision cutting. This CNC machine is connected to a 10HP rotary vane vacuum pump (twin pack optional), for quiet operation. For easy sheet alignment, (3) pop-up pins are included on the HDS Series, and are precisely placed to handle and align various size materials. The HDS Series CNC Machine is powered by brushless AC Servo digital motors and drives, and is powered by an easy-to-use and learn Osai PC based industrial controller.

Featured List

All steel construction

12 HP HSD high frequency automatic tool changer spindle

4-Zone vacuum t-slot table

Material pop-up pins for easy sheet alignment

Osai PC based Industrial grade CNC controller

Brushless digital AC servo motors and drives

Features

Steel Base

The HDS Series base frame is fabricated from heavy-duty tubular steel that is welded, precision machined and stress relieved so that the foundation remains true and steady over the operational life of the machine.

Gantry

The gantry is constructed of tubular steel with reinforcing ribs welded throughout the length of the column which results in a steady firm beam assembly. This quality engineering and workmanship result in smooth precision cutting.

Spindle

The HDS Series machine comes standard with a 12 HP HSD high frequency automatic tool changer spindle. This precision spindle requires no maintenance, uses industry standard ER collets and ISO 30 tool holders, is fully programmable with speeds from 6000 to 24000 RPM, and comes complete with a pneumatically retractable vacuum hood.

Vacuum Table

The vacuum plenum table surface is multi-zoned which allows the operator to easily switch from full sheet processing to smaller part processing (which requires a smaller segmented area). Zones can be turned off easily via control valves on the front of the machine. Gasketing can also be routed to accommodate various material sizes and styles.

Gantry Uprights

The gantry uprights are cast iron with heavy duty gussets formed into the casting. Each support is machined for housing the various drive assemblies including motors, bearings, and wiring harnesses.

Vacuum Shroud

The HDS includes a pneumatically operated vacuum hood that has concentrated air flow at the spindle thus efficiently cleaning up the dust and debris as it is routed.

Read More

Drive Train Assembly

The Techno HDS Series CNC Router uses precision helical gear racks on the X and Y axes. The mounting of the rack is inverted to help keep dust and debris from building up on the drive system, ensuring smooth motion and long term reliability. The precision gearbox is directly coupled to the Servo motor and pinion. This eliminates belt stretch inaccuracies assuring high-speed machining while the system positions the spindle accurately.

Tool Holder Clamp

The Techno HDS Series CNC Machine comes equipped with a tool holder clamp fixture, providing a much easier way of inserting and tightening the CNC router bits into your tool holder. This method is safer and easier.

Electronics

All the electrical components are housed and wired in a doubled-doored Nema 4 electrical enclosure. This allows for easy access and service when needed. All wiring is tagged so that when service is required, the customer can easily navigate the cabinet.

Tooling

The HDS Series machine includes an 8-position tool rack in the rear of the machine. The position of this rack allows for easy loading and unloading of material from either side of the machine.

Drive Motors

The HDS Series CNC Router utilizes AC Servo motors powered by Yaskowa drives. These motors require no regular maintenance — therefore, reducing any maintenance downtime.

Manual Pulse Generator

The MPG allows the operator to move around the machine, making for easy setup

ABOUT THE OSAI CONTROLLER

The Venture Plus model machine is controlled via an Industrial Osai open series PC based CNC controller. OSAI is based on multi-platform software architecture. The real time multi-task operating system offers accurate and safe axis control that can be completed with the system's own technological algorithms. Additionally, a standard Windows operating system provides a friendly and familiar operator interface. OSAI combines the ease-of-use, flexibility, and connectivity of a fully equipped Windows PC, with the power, durability, reliability, and serviceability of a true CNC machine controller.

Key features:

- Full automated tool length offset cycle

- Remote access

- Intuitive design and operation

- Skip functionality

- Backlash compensation

- Cutter compensation

- Full 3D capability with helical interpolation

- Highly Customizable

- Built-in editor for shop floor modifications

- Machine feed rate and spindle override control

- Continuous step jogging, or convenient hand-held pulse

- Generator can be used to fine tune positional locations

- CNC NC code previewer

- I/O machine status display

- Convenient vacuum pump switches on console interface

- Convenient pop-up pin switches on console interface

- Real time file execution

- Networkable

- System includes PC, monitor, keyboard, mouse, and work

- Platform on the control cabinet

Customer Reviews

I made our CNC upgrade close to 10 years ago. We came back to Techno to upgrade. Now, my 5×10 HDS Series and desktop machines are growing old with me… working hard and having fun. Our machines never disappoint. The people are Techno are hard working, dependable, and precise, just like their machines. Thank you for playing such a huge part in my continued success and growth" Christian MagroACM Solutions “We are extremely satisfied with both of our Techno CNC machines. Our new Titan Series has been a huge upgrade from our older Techno model. This new CNC machine has made our production a lot easier. The tool changer has been a game changer. I am finding myself performing tasks that I would normally complete by hand. Anyone considering getting a CNC, look no further than Techno. Buy your last CNC first" Tom DaliaGalloup Guitars "Purchasing the Techno CNC HDS 5×10 router is one of the best decisions we have made. Being in a business where versatility is essential in our equipment. There are days we start with cutting standard plywoods, shift to cutting 3” thick foam, then finish the day cutting Sintra and acrylic... all with immense ease. The best part of having our router is having a great team stand behind their product. Any questions we have get answered very quick. The Techno team is top-notch and their dedication rivals that of other machine companies. We are extremely happy and have no regrets. The machine has allowed us to compete with companies 10-100x our size" Timothy DavidBreakthrough Productions “Overall, I am extremely satisfied with all three of my Techno CNC routers. My second CNC purchase from Techno CNC was even easier to learn how to use, since it had the same controller as my Premium class Series. And now that I purchased Techno's new Titan Series CNC router a few months ago and learned about Win CNC controllers, I can do so much more” Jared MenkeJared's Gunstocks "I am impressed with Techno’s technical support and fast response, confirming our pre-sales research and concerns in picking the right company. You are a phone call away. We wanted to give our students a leg up on competition in other schools. We wanted to go with the best of the best. Adding the tool changer and vacuum table is a big deal. Another perk of our CNC is how we are never restricted by a project size" Jessie PerisonRandolph High School "We have lasers & 3D printers but the CNC routers offer so much more. Techno CNC machines allow us the ability to use a variety of different materials, sizes and thicknesses. Another benefit of CNC machinery is having not just one, but two. We have double the capabilities for students to work hands-on with the routers - allowing for more one on one time with the routers & a smoother workshop class. We are extremely pleased with how our routers run" Leah AegerterAnderson Ranch Art Studio "We had a small issue with our 10’ Techno CNC this morning and when your tech called, he was very helpful and professional. I just thought you should know your team is very good. Thank you and tell your team we are very appreciative" Spencer TerpeningSRC Refrigeration “My Techno CNC router has been an excellent machine to enter into the CNC world. When purchasing a CNC router, I found Techno to be extremely reliable. Whenever I called Techno for a simple tech support question, a living breathing person answered the phone, and I know I am always going to get the answer immediately. I never feel as though I am getting pushed around. That was huge for my purchasing decision" Rob StaropoliRobert Staropoli Cabinetry "I wanted to thank you for your tech support for my Techno CNC Venture. Almost every company who sells you a machine and promises service will not give you the time of day. I cannot express my gratitude on the help I have received from Techno over the past 8 years. You and the team at Techno CNC stand behind what you sell. Once again, I would like to thank you for your service and reliable machinery" Scott HoeferInsight Exhibits "I’ve been meaning to drop you guys a note letting you know how much we appreciate the quality of the CNC machine, and the service we receive from Techno CNC. Having had a year and a half of time with the machine, we truly value it’s dependability, and virtually trouble free operation. That, combined with the speedy, friendly and knowledgeable service, are things we do not take for granted. Thank you for providing a high quality product, and great service" Bill StumpNew York Tent “I love your machines. They are work horse machines! We recently used the vacuum table to laminate plywood with thick veneer using a 3mill plastic sheet. It’s amazing that we are still finding many more uses for this machine other than its main purpose. It has opened so many possibilities and has given us more independence; allowing us to do things we used to sub out. I love being able to keep things in house as it allows us to have more control over our quality of work” Neil O'Moore-KlopfReither Woodworking “Our curriculum has switched from an Industrial Maintenance format to Advanced Manufacturing. The centerpiece is our Techno CNC machine. Our Techno CNC delivers exactly what we want: quality, repeatability, and speed in the manufacturing process. Utilizing CNC technology allows us to bring real world manufacturing into our classroom and gives our students an edge as they prepare for future careers in the manufacturing industry” Keith HaleCaroline Career and Tech Center “We used to print these parts and have them sent to a local machine shop for finishing. Our new Techno Goliath Series now allows us to keep work in-house and requires no hand finishing; saving us a lot of time and money. We are extremely pleased the new Techno Goliath machine will help stream line our manufacturing process with increased efficiency, quality and accuracy” ManagersWitchita State University "Our 3-axis @technocnc CNC router is the beating heart of rootlab. Everything we build is meticulously designed by our design team. Once designed many of the components pass through the capable hands of our digital fabrication team before being handed off to the next department. From simple templates to complex 2.5D sculpting, we use the CNC to mill all types of sheet goods including plywood, MDF, hardwood, aluminum, foam, solid surface, and acrylic". Root LabRoot Lab Previous NextMACHINE Options

Take a Closer Look at What This Machine Can Do

Previous Next Previous NextMACHINE VIDEO GALLERY

Play Play Play Play Play Play Play Play Play Play Brochure Request a quoteThe HDS Series

Techno’s HDS Series CNC Machine is made up of all steel construction, providing the rigid foundation required for ultra-smooth routing results. The HDS Series CNC Router includes a 12 HP HSD automatic tool changer spindle with an 8-position tool rack, and comes standard with a pneumatically operated dust collection hood that concentrates air flow at the cutter, providing optimal dust collection performance. The multi-zone vacuum t-slot table is constructed from very hard Phenolic; an extremely stable material that holds tight tolerances for precision cutting. This CNC machine is connected to a 10HP rotary vane vacuum pump (twin pack optional), for quiet operation. For easy sheet alignment, (3) pop-up pins are included on the HDS Series, and are precisely placed to handle and align various size materials. The HDS Series CNC Machine is powered by brushless AC Servo digital motors and drives, and is powered by an easy-to-use and learn Osai PC based industrial controller.

Featured List

All steel construction

12 HP HSD high frequency automatic tool changer spindle

4-Zone vacuum t-slot table

Material pop-up pins for easy sheet alignment

Osai PC based Industrial grade CNC controller

Brushless digital AC servo motors and drives

Features

Steel Base

The HDS Series base frame is fabricated from heavy-duty tubular steel that is welded, precision machined and stress relieved so that the foundation remains true and steady over the operational life of the machine.

Gantry

The gantry is constructed of tubular steel with reinforcing ribs welded throughout the length of the column which results in a steady firm beam assembly. This quality engineering and workmanship result in smooth precision cutting.

Spindle

The HDS Series machine comes standard with a 12 HP HSD high frequency automatic tool changer spindle. This precision spindle requires no maintenance, uses industry standard ER collets and ISO 30 tool holders, is fully programmable with speeds from 6000 to 24000 RPM, and comes complete with a pneumatically retractable vacuum hood.

Vacuum Table

The vacuum plenum table surface is multi-zoned which allows the operator to easily switch from full sheet processing to smaller part processing (which requires a smaller segmented area). Zones can be turned off easily via control valves on the front of the machine. Gasketing can also be routed to accommodate various material sizes and styles.

Gantry Uprights

The gantry uprights are cast iron with heavy duty gussets formed into the casting. Each support is machined for housing the various drive assemblies including motors, bearings, and wiring harnesses.

Vacuum Shroud

The HDS includes a pneumatically operated vacuum hood that has concentrated air flow at the spindle thus efficiently cleaning up the dust and debris as it is routed.

Read More

Drive Train Assembly

The Techno HDS Series CNC Router uses precision helical gear racks on the X and Y axes. The mounting of the rack is inverted to help keep dust and debris from building up on the drive system, ensuring smooth motion and long term reliability. The precision gearbox is directly coupled to the Servo motor and pinion. This eliminates belt stretch inaccuracies assuring high-speed machining while the system positions the spindle accurately.

Tool Holder Clamp

The Techno HDS Series CNC Machine comes equipped with a tool holder clamp fixture, providing a much easier way of inserting and tightening the CNC router bits into your tool holder. This method is safer and easier.

Electronics

All the electrical components are housed and wired in a doubled-doored Nema 4 electrical enclosure. This allows for easy access and service when needed. All wiring is tagged so that when service is required, the customer can easily navigate the cabinet.

Tooling

The HDS Series machine includes an 8-position tool rack in the rear of the machine. The position of this rack allows for easy loading and unloading of material from either side of the machine.

Drive Motors

The HDS Series CNC Router utilizes AC Servo motors powered by Yaskowa drives. These motors require no regular maintenance — therefore, reducing any maintenance downtime.

Manual Pulse Generator

The MPG allows the operator to move around the machine, making for easy setup

ABOUT THE OSAI CONTROLLER

The Venture Plus model machine is controlled via an Industrial Osai open series PC based CNC controller. OSAI is based on multi-platform software architecture. The real time multi-task operating system offers accurate and safe axis control that can be completed with the system's own technological algorithms. Additionally, a standard Windows operating system provides a friendly and familiar operator interface. OSAI combines the ease-of-use, flexibility, and connectivity of a fully equipped Windows PC, with the power, durability, reliability, and serviceability of a true CNC machine controller.

Key features:

- Full automated tool length offset cycle

- Remote access

- Intuitive design and operation

- Skip functionality

- Backlash compensation

- Cutter compensation

- Full 3D capability with helical interpolation

- Highly Customizable

- Built-in editor for shop floor modifications

- Machine feed rate and spindle override control

- Continuous step jogging, or convenient hand-held pulse

- Generator can be used to fine tune positional locations

- CNC NC code previewer

- I/O machine status display

- Convenient vacuum pump switches on console interface

- Convenient pop-up pin switches on console interface

- Real time file execution

- Networkable

- System includes PC, monitor, keyboard, mouse, and work

- Platform on the control cabinet

Customer Reviews

I made our CNC upgrade close to 10 years ago. We came back to Techno to upgrade. Now, my 5×10 HDS Series and desktop machines are growing old with me… working hard and having fun. Our machines never disappoint. The people are Techno are hard working, dependable, and precise, just like their machines. Thank you for playing such a huge part in my continued success and growth" Christian MagroACM Solutions “We are extremely satisfied with both of our Techno CNC machines. Our new Titan Series has been a huge upgrade from our older Techno model. This new CNC machine has made our production a lot easier. The tool changer has been a game changer. I am finding myself performing tasks that I would normally complete by hand. Anyone considering getting a CNC, look no further than Techno. Buy your last CNC first" Tom DaliaGalloup Guitars "Purchasing the Techno CNC HDS 5×10 router is one of the best decisions we have made. Being in a business where versatility is essential in our equipment. There are days we start with cutting standard plywoods, shift to cutting 3” thick foam, then finish the day cutting Sintra and acrylic... all with immense ease. The best part of having our router is having a great team stand behind their product. Any questions we have get answered very quick. The Techno team is top-notch and their dedication rivals that of other machine companies. We are extremely happy and have no regrets. The machine has allowed us to compete with companies 10-100x our size" Timothy DavidBreakthrough Productions “Overall, I am extremely satisfied with all three of my Techno CNC routers. My second CNC purchase from Techno CNC was even easier to learn how to use, since it had the same controller as my Premium class Series. And now that I purchased Techno's new Titan Series CNC router a few months ago and learned about Win CNC controllers, I can do so much more” Jared MenkeJared's Gunstocks "I am impressed with Techno’s technical support and fast response, confirming our pre-sales research and concerns in picking the right company. You are a phone call away. We wanted to give our students a leg up on competition in other schools. We wanted to go with the best of the best. Adding the tool changer and vacuum table is a big deal. Another perk of our CNC is how we are never restricted by a project size" Jessie PerisonRandolph High School "We have lasers & 3D printers but the CNC routers offer so much more. Techno CNC machines allow us the ability to use a variety of different materials, sizes and thicknesses. Another benefit of CNC machinery is having not just one, but two. We have double the capabilities for students to work hands-on with the routers - allowing for more one on one time with the routers & a smoother workshop class. We are extremely pleased with how our routers run" Leah AegerterAnderson Ranch Art Studio "We had a small issue with our 10’ Techno CNC this morning and when your tech called, he was very helpful and professional. I just thought you should know your team is very good. Thank you and tell your team we are very appreciative" Spencer TerpeningSRC Refrigeration “My Techno CNC router has been an excellent machine to enter into the CNC world. When purchasing a CNC router, I found Techno to be extremely reliable. Whenever I called Techno for a simple tech support question, a living breathing person answered the phone, and I know I am always going to get the answer immediately. I never feel as though I am getting pushed around. That was huge for my purchasing decision" Rob StaropoliRobert Staropoli Cabinetry "I wanted to thank you for your tech support for my Techno CNC Venture. Almost every company who sells you a machine and promises service will not give you the time of day. I cannot express my gratitude on the help I have received from Techno over the past 8 years. You and the team at Techno CNC stand behind what you sell. Once again, I would like to thank you for your service and reliable machinery" Scott HoeferInsight Exhibits "I’ve been meaning to drop you guys a note letting you know how much we appreciate the quality of the CNC machine, and the service we receive from Techno CNC. Having had a year and a half of time with the machine, we truly value it’s dependability, and virtually trouble free operation. That, combined with the speedy, friendly and knowledgeable service, are things we do not take for granted. Thank you for providing a high quality product, and great service" Bill StumpNew York Tent “I love your machines. They are work horse machines! We recently used the vacuum table to laminate plywood with thick veneer using a 3mill plastic sheet. It’s amazing that we are still finding many more uses for this machine other than its main purpose. It has opened so many possibilities and has given us more independence; allowing us to do things we used to sub out. I love being able to keep things in house as it allows us to have more control over our quality of work” Neil O'Moore-KlopfReither Woodworking “Our curriculum has switched from an Industrial Maintenance format to Advanced Manufacturing. The centerpiece is our Techno CNC machine. Our Techno CNC delivers exactly what we want: quality, repeatability, and speed in the manufacturing process. Utilizing CNC technology allows us to bring real world manufacturing into our classroom and gives our students an edge as they prepare for future careers in the manufacturing industry” Keith HaleCaroline Career and Tech Center “We used to print these parts and have them sent to a local machine shop for finishing. Our new Techno Goliath Series now allows us to keep work in-house and requires no hand finishing; saving us a lot of time and money. We are extremely pleased the new Techno Goliath machine will help stream line our manufacturing process with increased efficiency, quality and accuracy” ManagersWitchita State University "Our 3-axis @technocnc CNC router is the beating heart of rootlab. Everything we build is meticulously designed by our design team. Once designed many of the components pass through the capable hands of our digital fabrication team before being handed off to the next department. From simple templates to complex 2.5D sculpting, we use the CNC to mill all types of sheet goods including plywood, MDF, hardwood, aluminum, foam, solid surface, and acrylic". Root LabRoot Lab Previous NextMACHINE Options

Take a Closer Look at What This Machine Can Do

Previous Next Previous NextMACHINE VIDEO GALLERY

Play Play Play Play Play Play Play Play Play Play Brochure Request a quoteThe HDS Series

Techno’s HDS Series CNC Machine is made up of all steel construction, providing the rigid foundation required for ultra-smooth routing results. The HDS Series CNC Router includes a 12 HP HSD automatic tool changer spindle with an 8-position tool rack, and comes standard with a pneumatically operated dust collection hood that concentrates air flow at the cutter, providing optimal dust collection performance. The multi-zone vacuum t-slot table is constructed from very hard Phenolic; an extremely stable material that holds tight tolerances for precision cutting. This CNC machine is connected to a 10HP rotary vane vacuum pump (twin pack optional), for quiet operation. For easy sheet alignment, (3) pop-up pins are included on the HDS Series, and are precisely placed to handle and align various size materials. The HDS Series CNC Machine is powered by brushless AC Servo digital motors and drives, and is powered by an easy-to-use and learn Osai PC based industrial controller.

Featured List

All steel construction

12 HP HSD high frequency automatic tool changer spindle

4-Zone vacuum t-slot table

Material pop-up pins for easy sheet alignment

Osai PC based Industrial grade CNC controller

Brushless digital AC servo motors and drives

Features

Steel Base

The HDS Series base frame is fabricated from heavy-duty tubular steel that is welded, precision machined and stress relieved so that the foundation remains true and steady over the operational life of the machine.

Gantry

The gantry is constructed of tubular steel with reinforcing ribs welded throughout the length of the column which results in a steady firm beam assembly. This quality engineering and workmanship result in smooth precision cutting.

Spindle

The HDS Series machine comes standard with a 12 HP HSD high frequency automatic tool changer spindle. This precision spindle requires no maintenance, uses industry standard ER collets and ISO 30 tool holders, is fully programmable with speeds from 6000 to 24000 RPM, and comes complete with a pneumatically retractable vacuum hood.

Vacuum Table

The vacuum plenum table surface is multi-zoned which allows the operator to easily switch from full sheet processing to smaller part processing (which requires a smaller segmented area). Zones can be turned off easily via control valves on the front of the machine. Gasketing can also be routed to accommodate various material sizes and styles.

Gantry Uprights

The gantry uprights are cast iron with heavy duty gussets formed into the casting. Each support is machined for housing the various drive assemblies including motors, bearings, and wiring harnesses.

Vacuum Shroud

The HDS includes a pneumatically operated vacuum hood that has concentrated air flow at the spindle thus efficiently cleaning up the dust and debris as it is routed.

Read More

Drive Train Assembly

The Techno HDS Series CNC Router uses precision helical gear racks on the X and Y axes. The mounting of the rack is inverted to help keep dust and debris from building up on the drive system, ensuring smooth motion and long term reliability. The precision gearbox is directly coupled to the Servo motor and pinion. This eliminates belt stretch inaccuracies assuring high-speed machining while the system positions the spindle accurately.

Tool Holder Clamp

The Techno HDS Series CNC Machine comes equipped with a tool holder clamp fixture, providing a much easier way of inserting and tightening the CNC router bits into your tool holder. This method is safer and easier.

Electronics

All the electrical components are housed and wired in a doubled-doored Nema 4 electrical enclosure. This allows for easy access and service when needed. All wiring is tagged so that when service is required, the customer can easily navigate the cabinet.

Tooling

The HDS Series machine includes an 8-position tool rack in the rear of the machine. The position of this rack allows for easy loading and unloading of material from either side of the machine.

Drive Motors

The HDS Series CNC Router utilizes AC Servo motors powered by Yaskowa drives. These motors require no regular maintenance — therefore, reducing any maintenance downtime.

Manual Pulse Generator

The MPG allows the operator to move around the machine, making for easy setup

ABOUT THE OSAI CONTROLLER

The Venture Plus model machine is controlled via an Industrial Osai open series PC based CNC controller. OSAI is based on multi-platform software architecture. The real time multi-task operating system offers accurate and safe axis control that can be completed with the system's own technological algorithms. Additionally, a standard Windows operating system provides a friendly and familiar operator interface. OSAI combines the ease-of-use, flexibility, and connectivity of a fully equipped Windows PC, with the power, durability, reliability, and serviceability of a true CNC machine controller.

Key features:

- Full automated tool length offset cycle

- Remote access

- Intuitive design and operation

- Skip functionality

- Backlash compensation

- Cutter compensation

- Full 3D capability with helical interpolation

- Highly Customizable

- Built-in editor for shop floor modifications

- Machine feed rate and spindle override control

- Continuous step jogging, or convenient hand-held pulse

- Generator can be used to fine tune positional locations

- CNC NC code previewer

- I/O machine status display

- Convenient vacuum pump switches on console interface

- Convenient pop-up pin switches on console interface

- Real time file execution

- Networkable

- System includes PC, monitor, keyboard, mouse, and work

- Platform on the control cabinet

Customer Reviews