How to Install the Ballnut

1-Note the orientation of the ball nut currently on the ball screw, you will need to install in same orientation

2-How to install:

-The new ball nut comes with a aluminum sleeve and two o-rings to prevent the sleeve from accidentally falling out of the ball nut.

-WARNING great care must be taken when handling the ball nut to assure the sleeve does not accidentally fall out of the ball nut. To install the ball nut , slide the sleeve over the ball screw drive end (machined threaded end). You will remove only one o-ring that is making contact with the ball screw rolled threads before sliding the sleeve onto the ball screw. Again you will double check ball nut orientation to make sure you are installing it correctly. Keeping constant pressure on the aluminum sleeve pressing it against the rolled ball screw threads, and carefully thread the ball nut onto the screw. DO NOT allow a cap between the sleeve and ball screw rolled threads otherwise this could cause balls from the nut to fall out. If this happens the ball nut will be destroyed and is irreparable. If you have two ball nuts to replace you will repeat procedure. If installing two ball nuts it’s assumed you have a 20mm pitch ball screw therefore every rotation of the ball nut will be 20mm (.787″). To set the proper spacing for the two ball buts you will use the black X-axis plate as your template. Rotate the one ball nut until the spacing is correct then install inside the linear bearings.

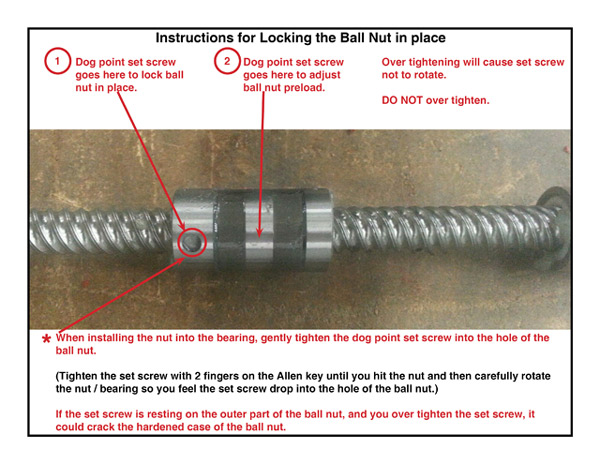

Instructions for Locking the Ball Nut in Place

|