The best cnc machines

Browse through our affordable, industrial grade cnc machinery to ensure business growth and power your creativity

Free

Lifetime

Support

Precision Components

Industrial

Controls

Free

Application

Consultation

On-Site

Services &

Training

Fast

Financing

a full line of cnc routers

learn about our cnc routers, cnc plasma cutters and cnc laser cutters

Titan Series

- 12HP HSD automatic tool changer

- 8-position tool rack

- Multi-zone vacuum t-slot table

- (3) material pop-up pins

- Brushless AC digital servo drive motors

- Easy to use hand held controller

PRICES STARTING AT

$44,750 – $51,500

Financing Available Here

Atlas Series

- 4HP HSD collet spindle

- Multi-zone vacuum t-slot table

- Brushless drive motors

- Easy to use and learn hand held controller

PRICES STARTING AT

Financing Available Here

HD II Tabletop

- 2HP HSD high frequency collet spindle

- Precision ball screws on all three axes

- Vacuum t-slot table

- Easy-to-use handheld controller.

PRICES STARTING AT

Financing Available Here

Venture Cabinet Nesting

- 12HP HSD automatic tool changer

- 8-position rotary carousel

- 9-spindle drill bank

- Multi-zone double layer high flow vacuum table

- Industrial PC based controller

PRICES STARTING AT

Financing Available Here

Venture Series

- 12 HP automatic tool changer

- Maintenance free brushless AC motors & drives

- 4-zone vacuum t-slot table

- Pneumatic material placement stops

- Hand-held generator with rotary hand wheel controls

- PC with flat screen monitor, keyboard and mouse

- Easy to use Techno CNC interface

- Open architecture works with all industry standard CAD/CAM software

Venture Plus Series

- 12 HP HSD automatic tool changer spindle

- 8-position tool rack

- (3) material pop-up pins

- Multi-zone vacuum t-slot table

- Brushless AC digital servo drive motors

- PC based industrial controller

PLEASE CALL

FOR PRICING

Financing Available Here

HDS Series

- 12 HP HSD automatic tool changer spindle

- 8-position tool rack

- (3) material pop-up pins

- Multi-zone vacuum t-slot table

- Brushless AC digital servo drive motors

- PC based industrial controller

PRICES STARTING AT

Financing Available Here

Goliath Series

- 12 HP HSD high frequency automatic tool changer spindle

- 8-position tool rack

- Pneumatically retractable vacuum hood

- Multi-zone vacuum t-slot table

- Easy-to-use hand-held controller

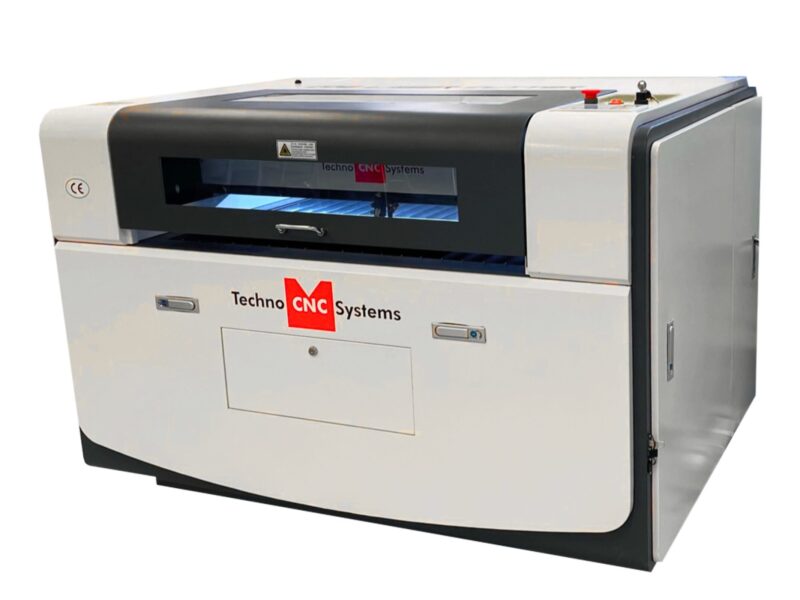

Laser Cutter

- All-steel construction

- Precision linear rails and bearings

- State-of-the-art CO2 laser Micro stepper controller

- Aluminum Honeycomb Table Water chiller

- Downdraft fume evacuation system

PRICES STARTING AT

Financing Available Here

Phoenix Plasma Series

- Available in 4′ x 4′, 4′ x 8′ and 5′ x 10′ stock sizes

- PC based WinCNC Controller

- Brushless drive motors

- Precision Helical Rack-n-Pinion on X and Y axes with ballscrew on the Z axes

- Unique design, easy to learn and operate

- Water table / Steel slats / Down drafts

- All steel construction for rigid platform Cuts up to 1.5” thick steel capacity

- High-speed cutting up to 800 IPM

- Magnetic Torch Break away

- Multiple torch options available

PRICES STARTING AT

Financing Available Here

Venus Series

- 20” x 30” Process area

- Precision ball screws on all three axes

- Hypertherm Torch

- Brushless micro stepper motors and controls

- Stainless steel water tray with vertical grid

- Automatic torch height control

- Linear rails and bearings

- Electronic torch breakaway

PRICES STARTING AT

Financing Available Here

BT 1212 Series

- Precision Ball Screws on all three axes

- 800 Watt (1 HP) variable speed spindle

- 8,000-24,000 RPM Brushless micro stepper motor control system

- Aluminum t-slot table

- Compatible with G code and M code

- Heavy duty construction

- Easy to use hand held controller

- Includes: 1/8, 1/4 collets and wrenches

PRICES STARTING AT

Financing Available Here

Small Investment, Large Return

Efficient, affordable and budget-friendly CNC routers

-

29 Trade Zone Drive

Ronkonkoma, NY 11779

- 631-648-7481

- technosales@technocnc.com

Get Connected with our Team

A Full Line of CNC Routers for Any Production Need

Parts, Accessories and Tooling

In-house parts, accessories, tooling, CNC router bits, plasma consumables and more available for same day shipping to keep your buisness on track with very minimal downtime.

Visit www.technocncshop.com

Free Technical Support for Life

We currently offer free technical support with real humans (no bots or automated messages) for the life of the machine. Call us M-F from 8:30 AM to 5:00 PM EST for assistance and help for FREE. We also offer on-sight and online training for an additional fee.

Financing Available

We’ve partnered with First Citizens Bank Equipment Finance to offer flexible financing options to our customers. First Citizens is known for equipment financing expertise & exceptional customer service. Click below to apply and learn more.

The Techno CNC Advantage

Why Buy CNC Equipment from Techno CNC?

Techno CNC Machinery Benefits

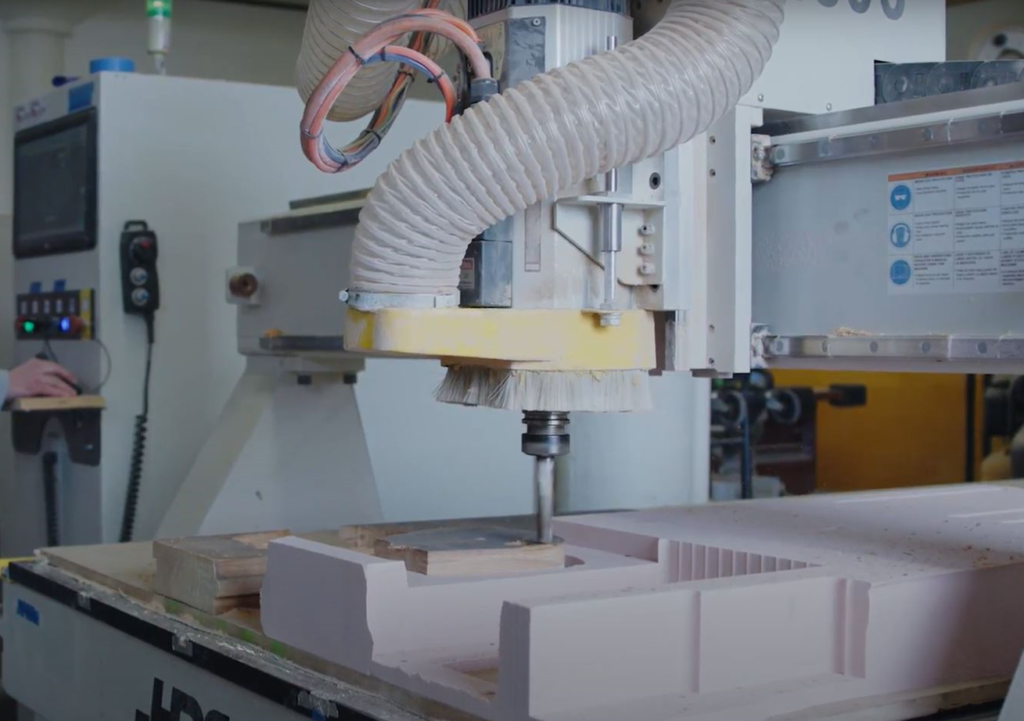

Techno CNC has sold and serviced thousands of CNC machines worldwide. We believe that high quality CNC machinery that ensures reliable cutting and machine longevity. It has become our mission to remain price conscious while delivering CNC solutions to businesses all across the globe. We are continuously studying technology and designing our own equipment to better serve our customers. Here at Techno CNC, we produce a vast number of machine models to meet any and all production needs and budgets. Our full line CNC routers and CNC plasma cutters consist of large format and small table top sizes with a vast assortment of accessories to meet any production need. We use our CNC experience to help sign makers, woodworkers, mill workers, artists, general fabricators and more with their production needs. Our goal is to help businesses create more parts by spending less money and provide companies with the most advanced CNC technology. Our CNC equipment is designed to route, carve, drill, and engrave in wood, plastic, foam, and aluminum for all businesses looking to advance their business.

Materials our Machinery Can Cut:

Solid Wood

Cottonwood, Pine, Redwood, Ash, Oak, Beech, Birch, Cherry, Mahogany, Hard maple, Poplar, Teak, Walnut, Hickory, Purple Heart, Leopardwood, Tigerwood, Cocobolo, Bloodwood, Alder, Aspen, Basswood, Beech, Yellow Birch, Cypress, Red Elm, Gum, Hackberry, Pecan, Pacific Coast maple, Red Oak, Sassafras, Sycamore, Black Walnut, White Oak, Willow, African Padauk, Bolivian Rosewood, Hondura Mahogany, Wenge, Spanish Cedar.

Soft Wood

Pine, Soft Maple, Fir, Spruce, Hemlock, Cedar, Redwood.

Composite Wood

OSB, MDF, LDF, Melamine, Particle Board, Plywood, Masonite.

Plastics

ABS, Polycarbonate, Polyethylene, PVC, Polypropylene, Polystyrene, Cast and Extruded Acrylic, HDPE, UHMW, Marine PVC, Lexan, Phenolic, Sintra, Nylon, Lucite, Solid Surface Materials, Luan, PET, Acetate, VHMW, Mica.

Foam

EVA, Precision Board, Sign Foam, Polystyrene, Polyethylene, Styramfoam, Polyurethane, Foam Rubber, Silicone Rubber, Urethane.

Non-Ferrous Metals and More below

Machinable Wax, Ren Board, Vinyl Coated Panels, Gypsum, Butter Board, Fiberglass, Magnetic Rubber Mats, Composites, Leather, Mother-of-Pearl, Wood Veneers, G10, Delrin, Mat Board, Rubber, Modeling Clay.

Applications

Cabinetry, Woodworking, Signmaking, Carvings, Musical Instruments, Aerospace, Boat Decking, Jewlery Manufacturing, Channel Lettering, Modelmaking, Etsy Shop Production, Solid Surface Production, Counter Production, Door making, Boat building, Plastic Packaging, Box Manufacturing, Engraving, Fencing, Roofing, Name tags, Pool Cue Manufacturing, Plastics and Foam, 3D Modeling, Prototyping, Metal Fabrication and steel, Theatre Props and Exhibits, Architectural Millwork, Cabinetry, Woodcarving, Aluminum and Brass Machining, Pole Manufacturing, Gunstocks and Pistol Grips

CNC Machines are the new tool choice for signshops. A CNC router from Techno CNC will offer the versatility and ease that your sign business requires to keep up with competitors.

From basic wood carvings to furniture, kitchen design, and more, a CNC router is the perfect tool to add to your woodshop to ensure business expansion.

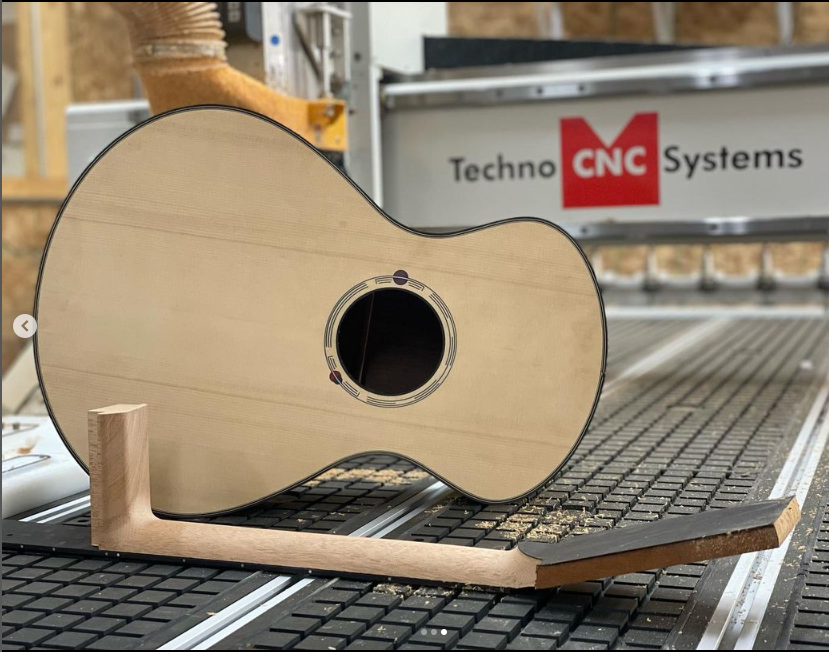

We have sold hundreds of our CNC machines to luthiers. Our CNC equipment offers the quick yet accurate finish and intricate detail that some of the world’s finest guitar makers require when producing guitars, fretboards, rosettes, inlays, jigs, cauls, and more.

Techno CNC Systems Educational Sector offers high speed, affordable industrial quality CNC Routers and CNC Plasmas in a wide range of sizes with work areas available from 12″ x 12″ to 5′ x 10′. All machines offer endless STEM opportunities. Every machine is installed and supported by local Techno CNC Systems representatives to ensure a successful startup.

The world’s finest craftsmen and manufacturers use industrial-grade CNC routers to produce custom and mass produced furniture, decor, and modern, mid-century, and contemporary furnishings, appliances, amenities, and fixtures.

We are now changing the course of drywall panel fabrication with CNC machinery from Techno CNC. Computer-aided measurements and cuts mean repeated installations can be produced more precisely and efficiently than ever.

Custom car shops typically cater to high profile clients and many times the deadlines are tight. Our CNC machines deliver high speed and accuracy along with excellent cut quality. Create custom speaker boxes, TV add ons, subs, logos, numbers, raptor box, grills, door panels, roof mounts and more.

Expand your gunstock business with a CNC. Reproducing gun stocks and pistol grips using conventional methods, such as pantograph machines and skilled craftsmen using hand tools is out-dated. These methods are very time-consuming and costly, preventing your business from being able to manufacture and reproduce rare gun stocks and grips accurately, efficiently, and quickly.

Our CNC machinery is a great additive to prototyping businesses. Our CNC routers allow you to accelerate the design process and quickly iterate through multiple options. With our CNC routers, you are able to produce façade, ceiling and furniture prototypes in-house the day they are designed.

Create nested cabinet parts, pin holes, dados, doors, drawer boxes and fronts, shelves, 3D designs, rabbets and more with Techno CNC routers for your cabinet making shop.

Create unforgettable immserive experiences and unique spaces with a CNC router for your fabrication and design company. Our CNC routers are the perfect tool to help create pieces for exhibitions, museums, site amenities, public arts, rockwork, attractions, theme parks, zoos, marketing firms, film studios, architects, and more.

Our CNC machinery is a great additive to for boat building and manufacturing. Fabricate your custom boat parts with a Techno CNC Router. Our CNC machinery can produce custom dash panels, bait tanks, coolers, boat decking and livewell lids.

FAQS

Brief list of FAQs

Our CNC routers are made of industrial-grade CNC components to meet the demands of many applications including Cabinetry, Woodworking, Signmaking, Carvings, Musical Instruments, Aerospace, Boat Decking, Jewlery Manufacturing, Channel Lettering, Modelmaking, Etsy Shop Production, Solid Surface Production, Counter Production, Door making, Boat building, Plastic Packaging, Box Manufacturing, Engraving, Fencing, Roofing, Name tags, Pool Cue Manufacturing, Plastics and Foam, 3D Modeling, Prototyping, Metal Fabrication and steel, Theatre Props and Exhibits, Architectural Millwork, Cabinetry, Woodcarving, Aluminum and Brass Machining, Pole Manufacturing, Gunstocks and Pistol Grips to name a few. Our CNC routers give you the advantage to compete with competitors and give you the competitive edge you need to expand your business.

We have over 42 years of experience, knowledge, and history of manufacturing production, industrial-grade CNC systems, engineered to produce greater force, faster speeds, and more precision than any other CNC systems on the market. Techno CNC Systems offers the best CNC routers, CNC plasma cutters and CNC laser cutters for materials such as Cottonwood, Pine, Redwood, Ash, Oak, Beech, Birch, Cherry, Mahogany, Hard maple, Poplar, Teak, Walnut, Hickory, Purple Heart, Leopardwood, Tigerwood, Cocobolo, Bloodwood, Alder, Aspen, Basswood, Beech, Yellow Birch, Cypress, Red Elm, Gum, Hackberry, Pecan, Pacific Coast maple, Red Oak, Sassafras, Sycamore, Black Walnut, White Oak, Willow, African Padauk, Bolivian Rosewood, Hondura Mahogany, Wenge, Spanish Cedar, plastics such as ABS, Polycarbonate, Polyethylene, PVC, Polypropylene, Polystyrene, Cast and Extruded Acrylic, HDPE, UHMW, Marine PVC, Lexan, Phenolic, Sintra, Nylon, Lucite, Solid Surface Materials, Luan, PET, Acetate, VHMW, Mica, and various foams, soft woods, and Non-Ferrous Metals. Representing over 40 years of experience and expertise, our engineering team of CNC experts are continuously studying technology and designing our own line of CNC equipment to better serve our customers and different application needs.

We offer free technical support for the life of the machine. Our experienced technical support team offers real-time people to readily answer your calls – no automated technical support systems here

Techno CNC now offers a one stop CNC shop to purchase and replenish all of your tooling, CNC parts and accessories, CNC router bits, tool kits, plasma consumables, apparel, and replacement parts. We offer overnight delivery and same day shipping if need be.

Shop online at www.technocncshop.com

Techno CNC is proud to introduce our new CNC router bit product line. Techno CNC has developed tooling kits for specific routing market applications, making tooling selection for production shops easy

Specializing in industrial quality solid carbide cutting tools for the woodworking, plastics, and aluminum industries.

Techno CNC offers flexible financing. We have partnered with CIT to offer flexible financing options to our customers who are looking to purchase the equipment they need without a significant cash burden. We have specifically chosen to work with CIT because of the company’s expertise in equipment financing. With CIT, you could be eligible for rates, terms and service that you might not experience with other companies. Get the equipment that’s right for you without having to sacrifice quality or financial stability. Financing could be the best payment option for your next purchase for a number of reasons.

Tax benefits:

If you choose either an EFA or Lease with $1 residual, you can take advantage of Section 179 to accelerate your depreciation expense in a single year. If you choose a Lease with an FMV residual, financed equipment can be deducted as an operating expense in the period in which they’re paid, reducing the overall cost. Payments are also treated as expenses on the income sheet, so there’s no need to worry about depreciation.

-

29 Trade Zone Drive

Ronkonkoma, NY 11779

- 631-648-7481

- technosales@technocnc.com