HDS DUAL BED CNC ROUTER

DESCRIPTION:

FEATURES:

- 12 HP HSD high frequency automatic tool changer spindle

- Osai PC Based Industrial grade CNC controller

- Maintenance free brushless AC servo motors and drives

- 4-Zone vacuum t-slot table

- Pneumatic operated dust collection hood

- Pop-up pins for easy sheet alignment

- PC with flat screen monitor, keyboard and mouse

- Easy to use Techno CNC Interface

- Open architecture works with all industry standard CAD/CAM software

FEATURES

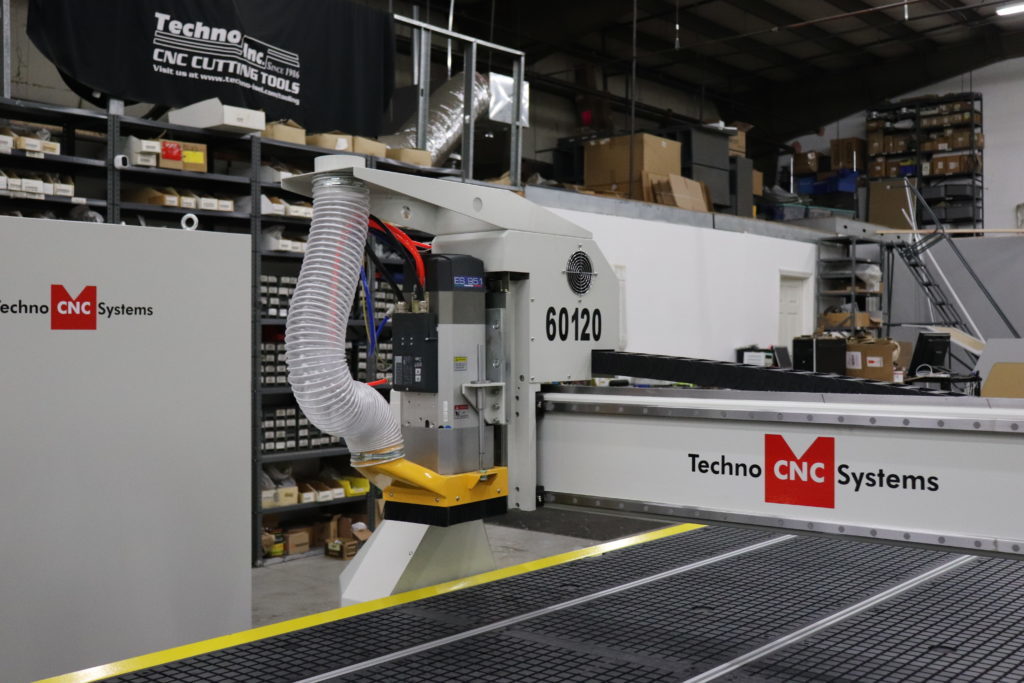

BASE FRAME

The HDS Dual Bed Series base frame is fabricated from heavy-duty tubular steel that is welded, precision machined and stress relieved so that the foundation remains true and steady over the operational life of the machine.

SPINDLE

The HDS Dual Bed Series machine comes standard with a 12 HP HSD high frequency automatic tool changer spindle. This precision spindle requires no maintenance, uses industry standard ER collets and ISO 30 tool holders, is fully programmable with speeds from 6000 to 24000 RPM, and comes complete with a pneumatically retractable vacuum hood.

TOOLING

TOOL CLAMP HOLDER

The Techno HDS Series Dual Bed CNC Machine comes equipped with a tool holder clamp fixture, providing a much easier way of inserting and tightening the CNC router bits into your tool holder. This method is safer and easier.

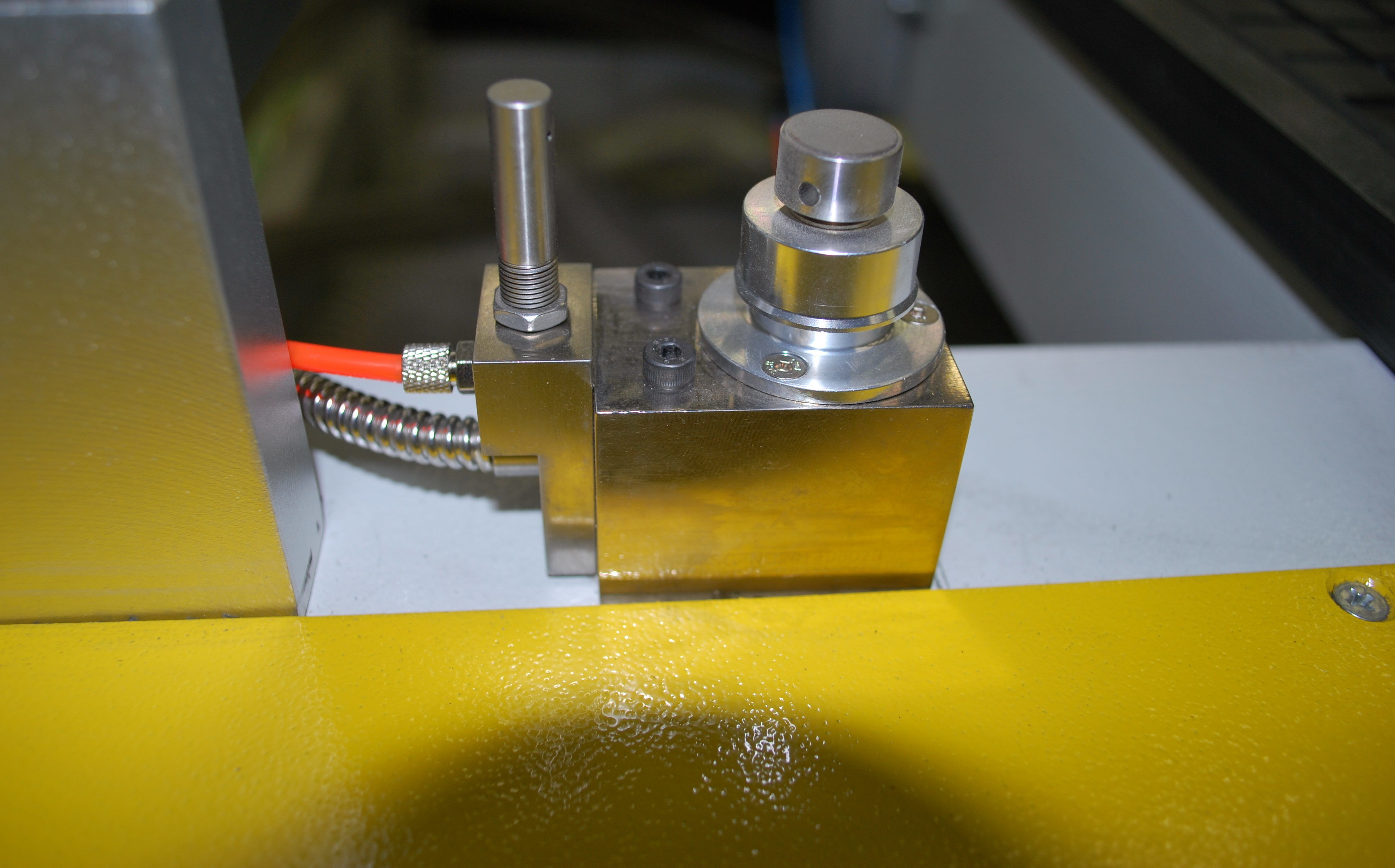

TOOL CALIBRATION

Automatic tool calibration pad is designed for easy and accurate recording of tool length off-sets

VACUUM SHROUD

The HDS Dual Bed includes a pneumatically operated vacuum hood that has concentrated air flow at the spindle thus efficiently cleaning up the dust and debris as it is routed.

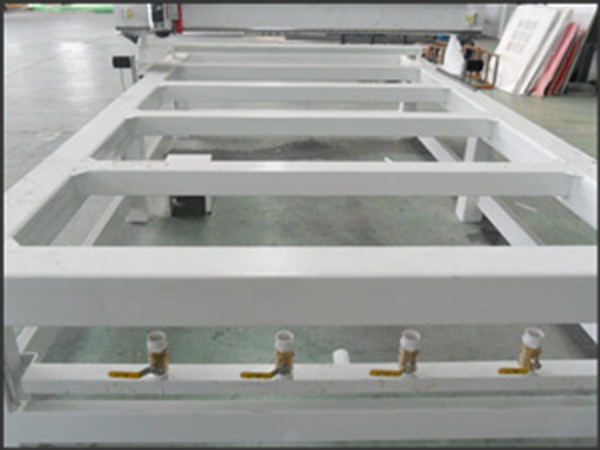

VACUUM TABLE

The vacuum plenum table surface is multi-zoned which allows the operator to easily switch from full sheet processing to smaller part processing (which requires a smaller segmented area). Zones can be turned off easily via control valves on the front of the machine. Gasketing can also be routed to accommodate various material sizes and styles.

POP-UP PINS

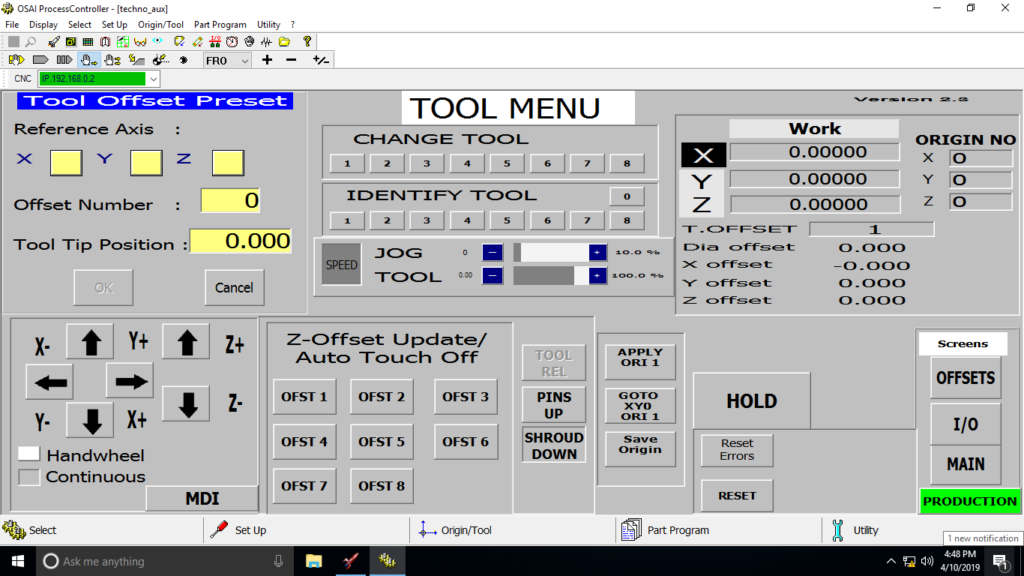

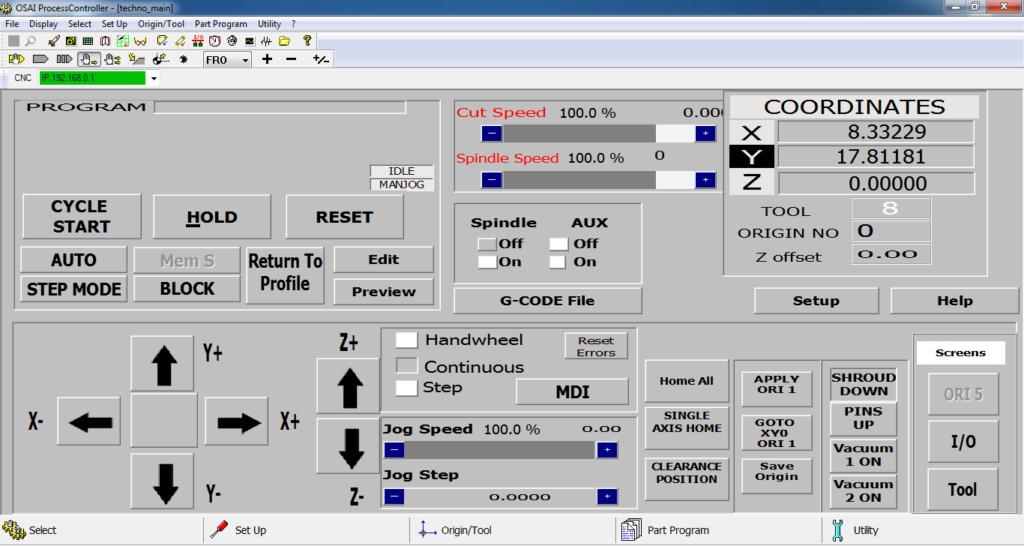

Controller

Techno CNC’s HDS Dual Bed Windows-Based G-Code Osai Interface is included with each machine and is an indispensable tool in any CNC Router application. Its open architectural design accepts G-Code files from any industry standard CAD/CAM software package, and can operate using inch or metric units and is highly customizable to better suite your needs. Customers that are new to automation find the Techno CNC Interface easy to learn and operate. Most are up and running in less than one day of training. They find the intuitive design and functions easy to use and remember. The most fundamental controls and displays are all visible on the main page. Customers soon discover that just because the Techno CNC Interface is easy to use, it does not mean that it is not a comprehensive CNC program.

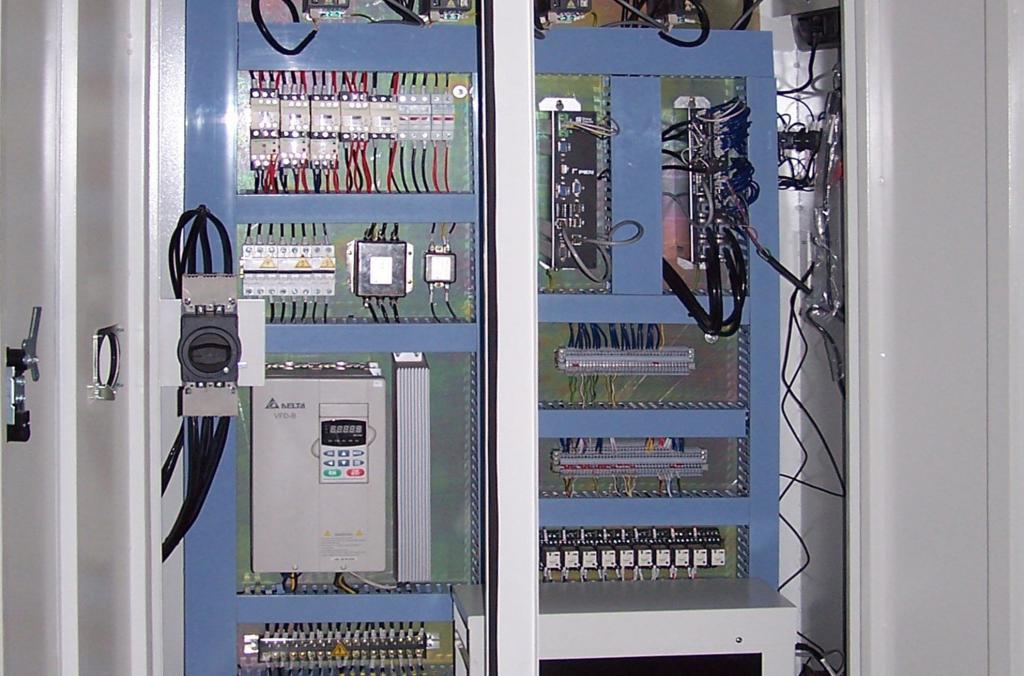

ELECTRONICS

All the electrical components are housed and wired in a doubled-doored Nema 4 electrical enclosure. This allows for easy access and service when needed. All wiring is tagged so that when service is required, the customer can easily navigate the cabinet.

Manual Pulse Generator (MPG)

The MPG allows the operator to move around the machine, making for easy setup

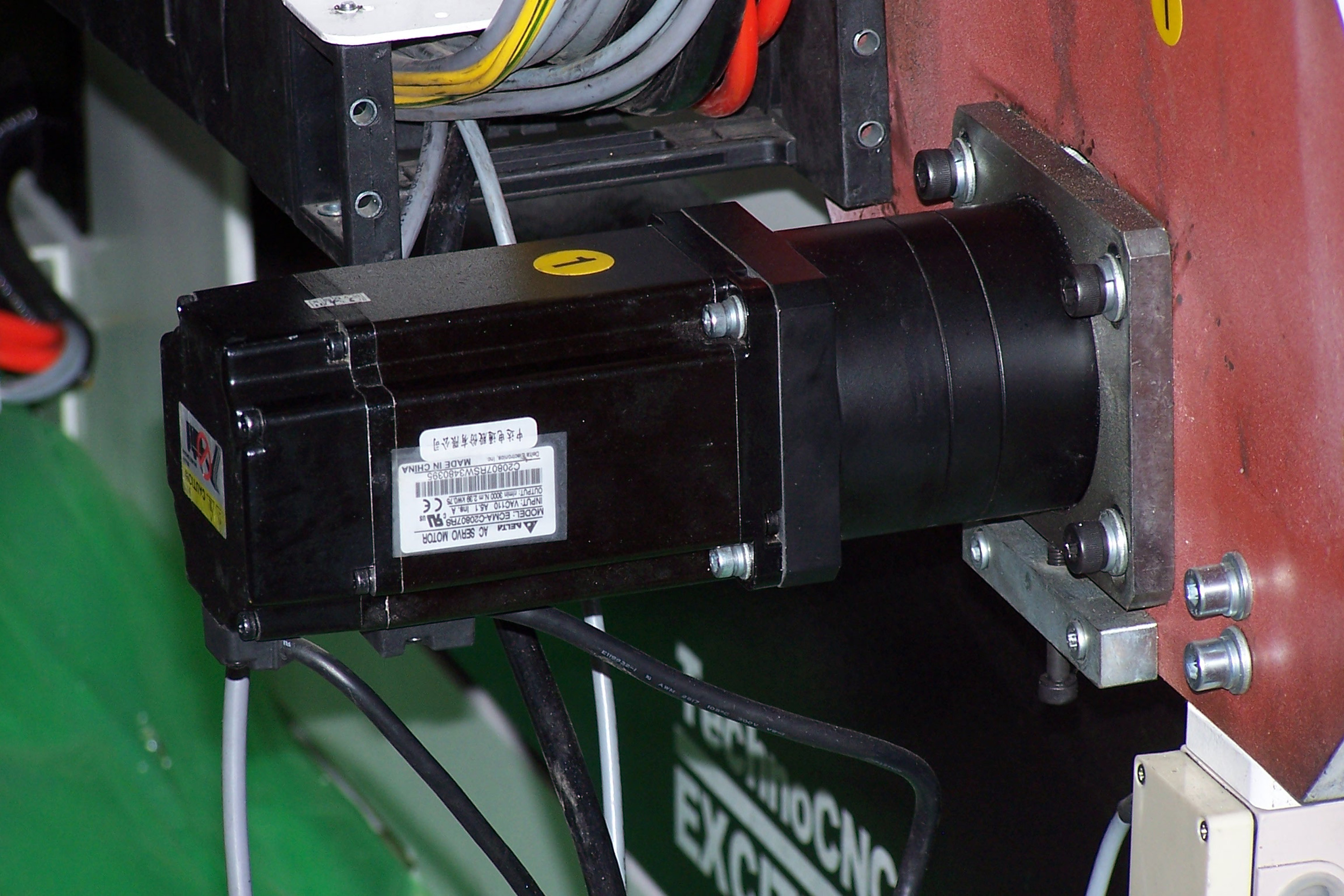

DRIVE MOTORS

The HDS Dual Bed Series CNC Router utilizes AC Servo motors powered by Yaskowa drives. These motors require no regular maintenance — therefore, reducing any maintenance downtime.

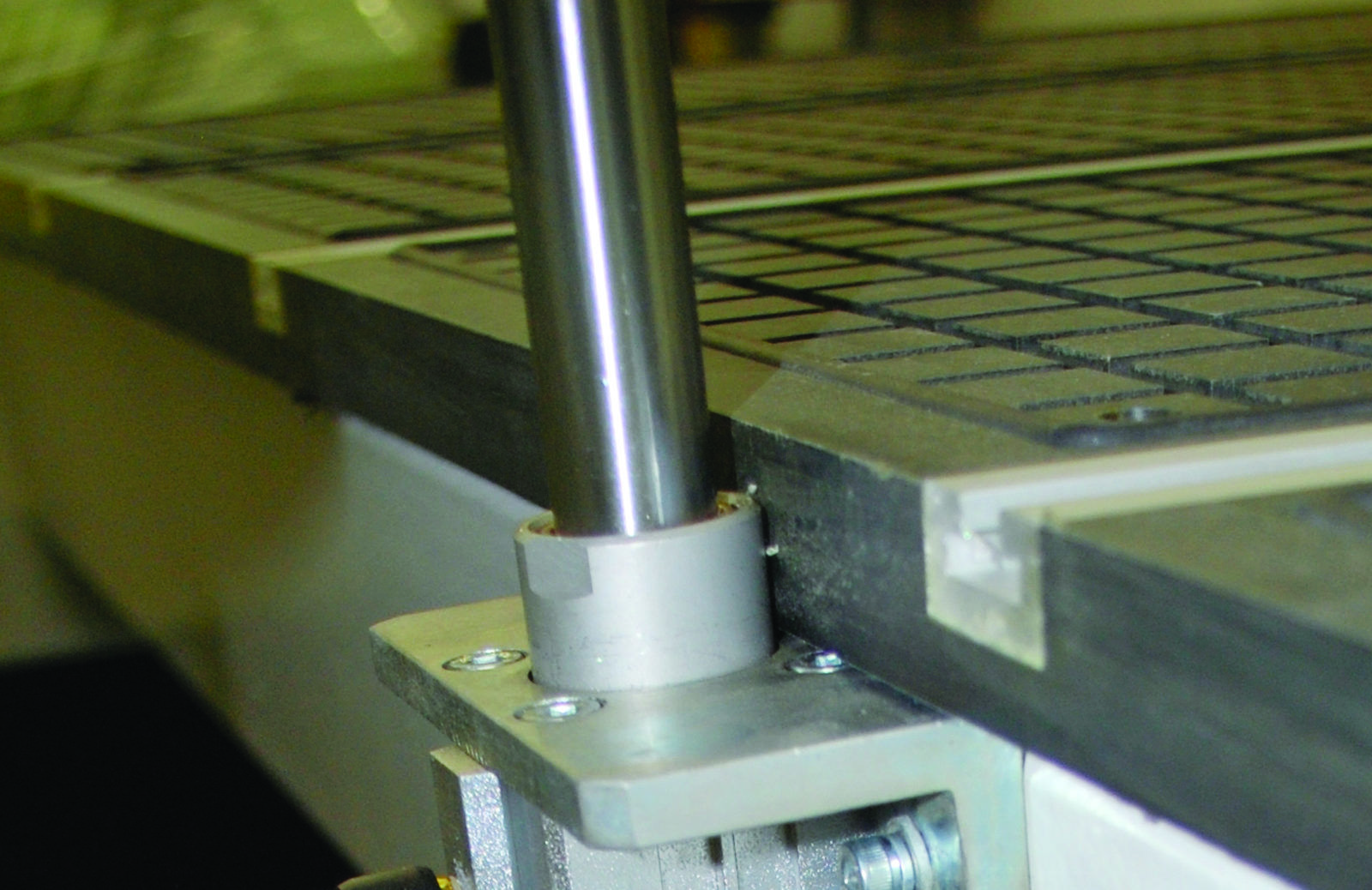

DRIVE TRAIN ASSEMBLY

The Techno HDS Dual Bed Series CNC Router uses precision helical gear racks on the X and Y axes. The mounting of the rack is inverted to help keep dust and debris from building up on the drive system, this assures smooth motion and long term reliability. The precision gearbox is directly coupled to the Servo motor and pinion. This eliminates belt stretch inaccuracies assuring high-speed machining while the system positions the spindle accurately

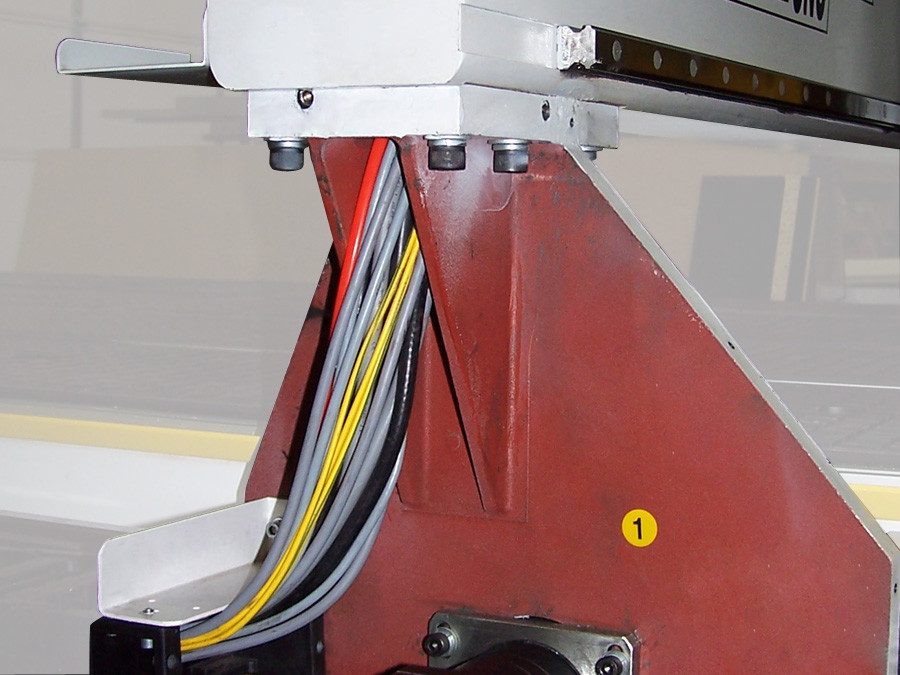

GANTRY

The gantry is constructed of tubular steel with reinforcing ribs welded throughout the length of the column which results in a steady firm beam assembly. This quality engineering and workmanship result in smooth precision cutting.

GANTRY UPRIGHTS

The Gantry uprights are cast iron with heavy duty gussets formed into the casting. Each support is machined for housing the various drive assemblies including motors, bearings, belts, and wiring harnesses.

OPTIONS

VACUUM PUMP

Techno offers Becker Rotary Vane vacuum pumps which are quiet, clean, and require minimal maintenance. The standard size we offer is a 10 HP or twin pack, which incorporates two 10 HP pumps mounted on a steel frame. These pumps pull 25” Hg @173CFM each. This level of vacuum is essential for holding the parts in place while being routed.

Take a Closer Look