ATLAS DIGITAL REGISTRATION

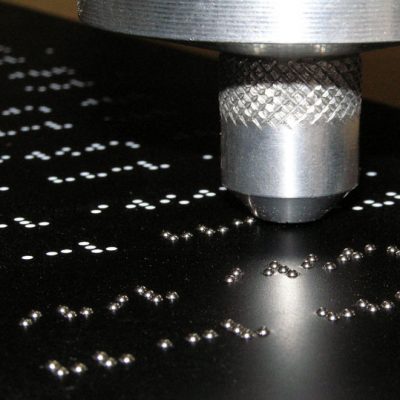

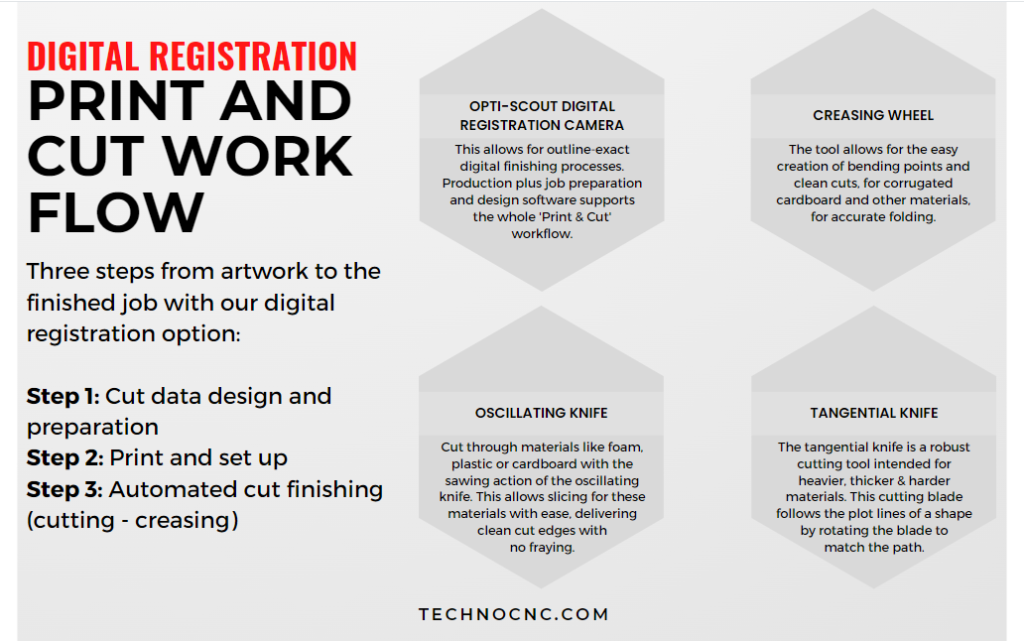

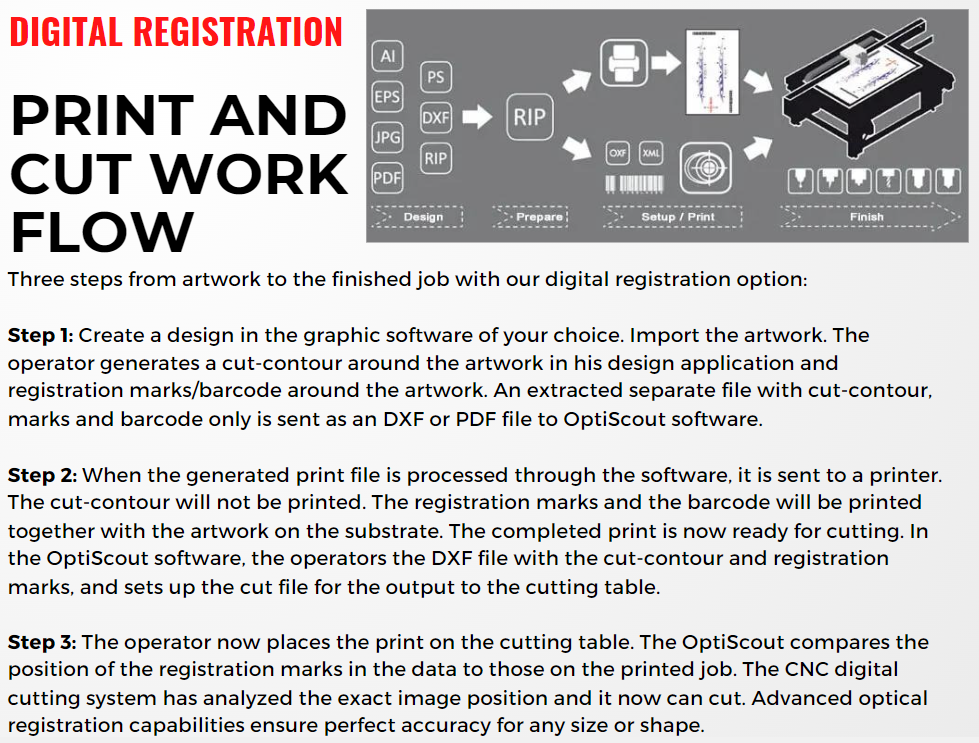

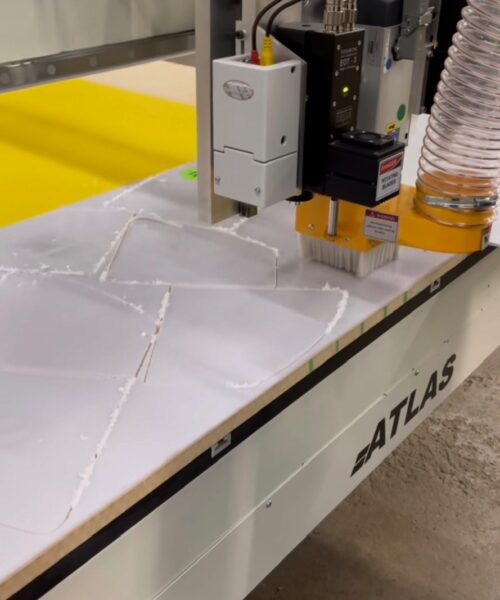

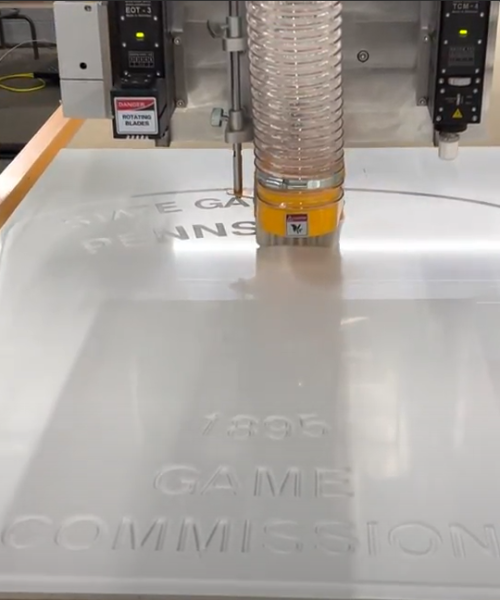

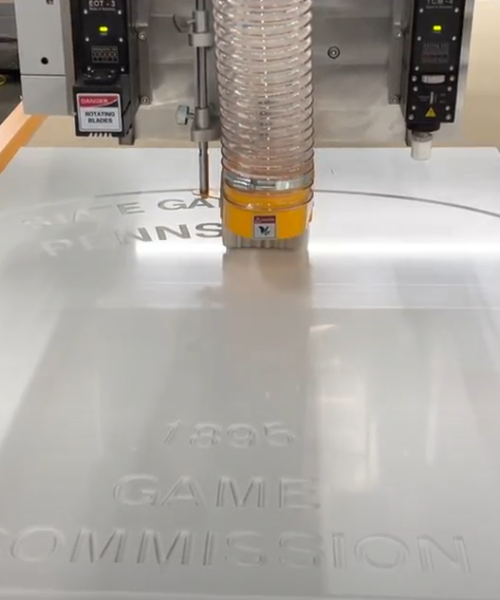

Techno’s New Atlas Series Digital Registration Cutting System is a heavy-duty, high-performance, affordable CNC System. The Atlas machine comes standard with a 4HP HSD collet spindle, with multi-zone vacuum table, and 10HP rotary vane vacuum pump. The Atlas machine can be equipped with a variety of different cutting head such as an electronic oscillating knife, creasing wheel, drag knife, and an Optiscout Digital Software Suite. The machine registers, routes, and cuts with precision at high speeds providing Sign and Graphics Shops a complete CNC digital finishing solution. The Atlas Series Digital Cutting System registers, routes and cuts with precision at high speeds – print and cut workflow. The operator loads the material, selects the image for routing, and the software automatically recognizes the media marks, compensating for skew, distortion, and image drift, and proceeds in cutting the pattern.

Featured List

4×4, 4×8 and 5×10 Standard sizes

All Steel Construction

4 HP HSD High Frequency Collet Spindle

Multi-zone vacuum table

Maintenance free brushless micro stepper drive motors

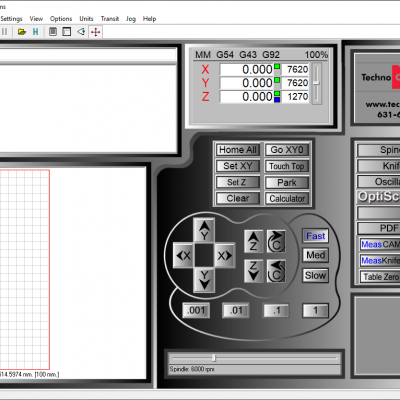

PC Based WinCNC controller

Automatic tool calibration

Features

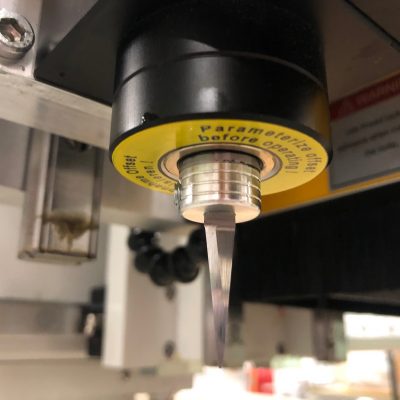

Spindle

The Atlas machine comes standard with a 4HP HSD high frequency collet spindle. These precision spindles require no maintenance, use industry standard ER collets, fully programmable speeds from 6000 to 18000 RPM, and comes complete with vacuum hood / hose support system and wrenches.

Gantry

The gantry is constructed of tubular steel with reinforcing ribs, welded throughout the length of the column, which results in a steady firm beam assembly. This quality engineering and workmanship result in smooth precision cutting.

Vacuum Table

The vacuum plenum table surface is single-zoned which is controlled via main gate valve. The table can be zoned by easily moving gasket around to customize specific sections. Gasketing can also be routed to accommodate various material sizes and styles

Tool Calibration

Automatic tool calibration pad allows for easy and accurate “Z” zero position.

Electronics

All the electrical components are housed and wired in a doubled-doored Nema electrical enclosure. This allows for easy access and service when needed. All wiring is tagged so that when service is required, the customer can easily navigate the cabinet. In addition, the cabinet serves as a work bench for the tools.

Drive Train Assembly

Techno CNC Systems uses new-generation precision helical rack and pinion drives with high dynamic performance and accuracy. These pinion drives deliver ultra smooth motion, power, and speed to the equipment. The helical pinion is directly driven by the digital AC servo motor with ultra-quite performance. The result of this new generation helical drive is superior cut quality, accuracy and machine longevity. This technology allows Techno to build large format machines that deliver speed and accuracy where ball screw driven machines are limited.

Customer Reviews

MACHINE Options

Small Investment, Large Return

Efficient, affordable and budget-friendly CNC routers

-

29 Trade Zone Drive

Ronkonkoma, NY 11779

- 631-648-7481

- technosales@technocnc.com

Get Connected with our Team

Follow us on Instagram

GET INSPIRED!

@technocnc

Be the first to know about new CNC machinery, CNC plasma cutters, CNC lasers, CNC projects, CNC tips and tricks, and so much more!