CNC Base Frame | 02.29.2024 | Techno CNC Systems Blog | 2 Minute Read

WHY IS THE BASE FRAME OF A CNC SO IMPORTANT?

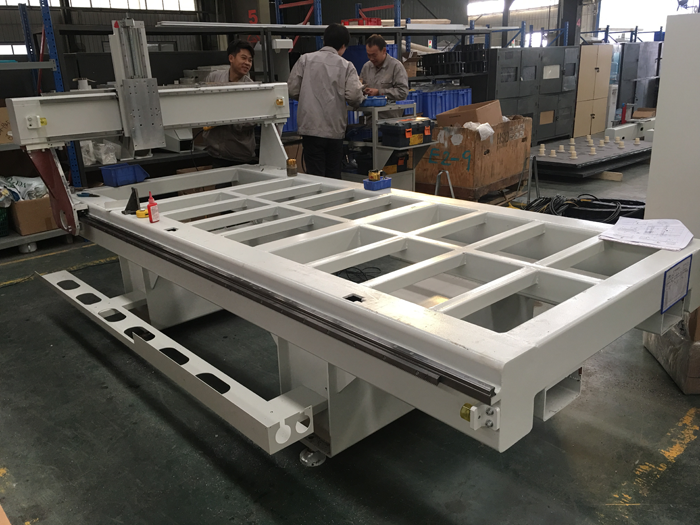

Machine frame construction is essential to the machine’s performance because, literally, everything is riding on it. At Techno, our engineers use Finite Element Analysis design software (CAD/CAM), which allows them to analyze the steel frame loads. This advanced technology allows our engineers to design and build frames that stand the test of time. The process of manufacturing a precision steel frame starts with the tubular steel weldment. Once the assembly is complete, the frame goes to stress relieving. This process relaxes the weld. Once the weld is relaxed, the metal will not change. If this process was not complete, time would eventually allow the welds to relax themselves thus changing the machine’s dimensions.

Once the stress relieving process is done, the frame is rough machined on a 5-axis milling machine. After the rough machining process is complete, it goes back to stress relieving for one more treatment, then back to the 5-axis mill for its last precision machining cycle. The last process trues up all the linear rails and helical rack machining locations, assuring precise parallelism and perpendicularity. It’s this precision that the X-axis gantry and Z-axis ride on.